Piling machine for containing river dike break

A technology for pile drivers and river dams, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of prolonged containment work, great effort, and difficulties in containment, and achieves faster embedding speed and simpler production. , the effect of speeding up the rescue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

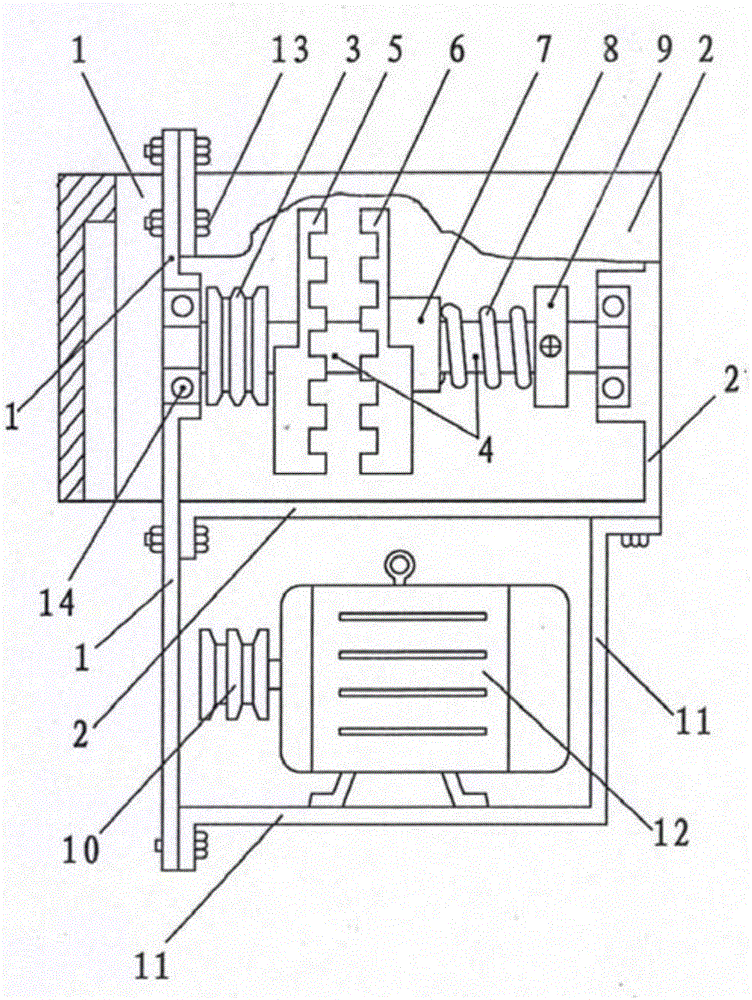

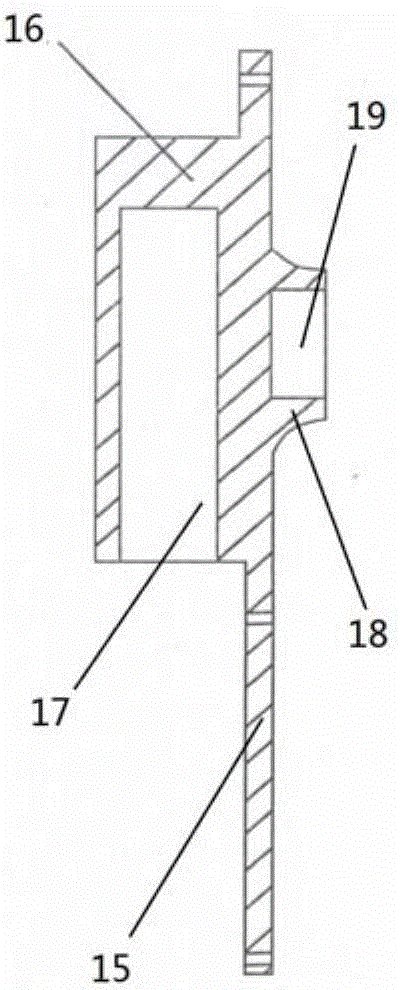

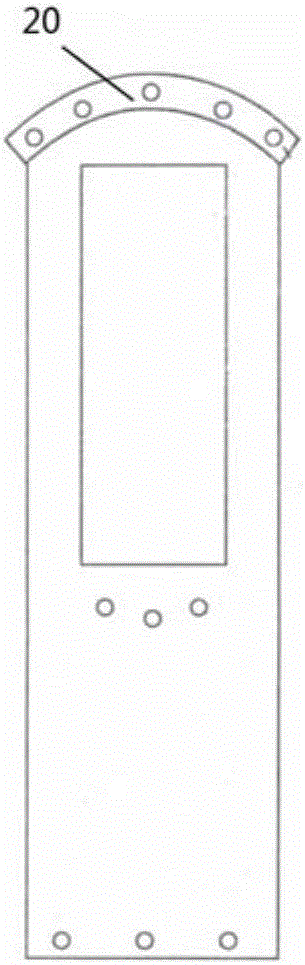

[0019] Such as figure 1 , a pile driver for containment of river dam collapse, which includes a special-shaped hammer 1, a support frame 2, a main shaft pulley 3, a main shaft 4, an active eccentric wheel 5, a passive eccentric wheel 6, a special-shaped sleeve 7, a spring 8, and a spring collar 9 , motor pulley 10, motor support base 11, motor 12, fastening bolt 13 and bearing 14, such as figure 2 and image 3 The middle part of the special-shaped hammer 1 is an elongated flat plate structure 15, and one side of the flat plate structure 15 is provided with an elongated hammer head 16 integrally formed with the flat plate structure 15, and a hammer head 16 is opened from the lower end. An impermeable mounting hole 17, the other side of the flat plate structure 15 protrudes and is provided with a cylindrical boss 18 integrally formed with the flat plate structure 15, and the middle part of the cylindrical boss 18 is provided with a circular recess that is assembled and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com