Flexible shock-absorbing clutch mechanism

A clutch mechanism and vibration type technology, applied in clutches, slitting machinery, mechanical equipment, etc., can solve the problems of unsolved clutch mechanism, high-frequency vibration of the handle, improve reliability and safety, and solve high-frequency vibration. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

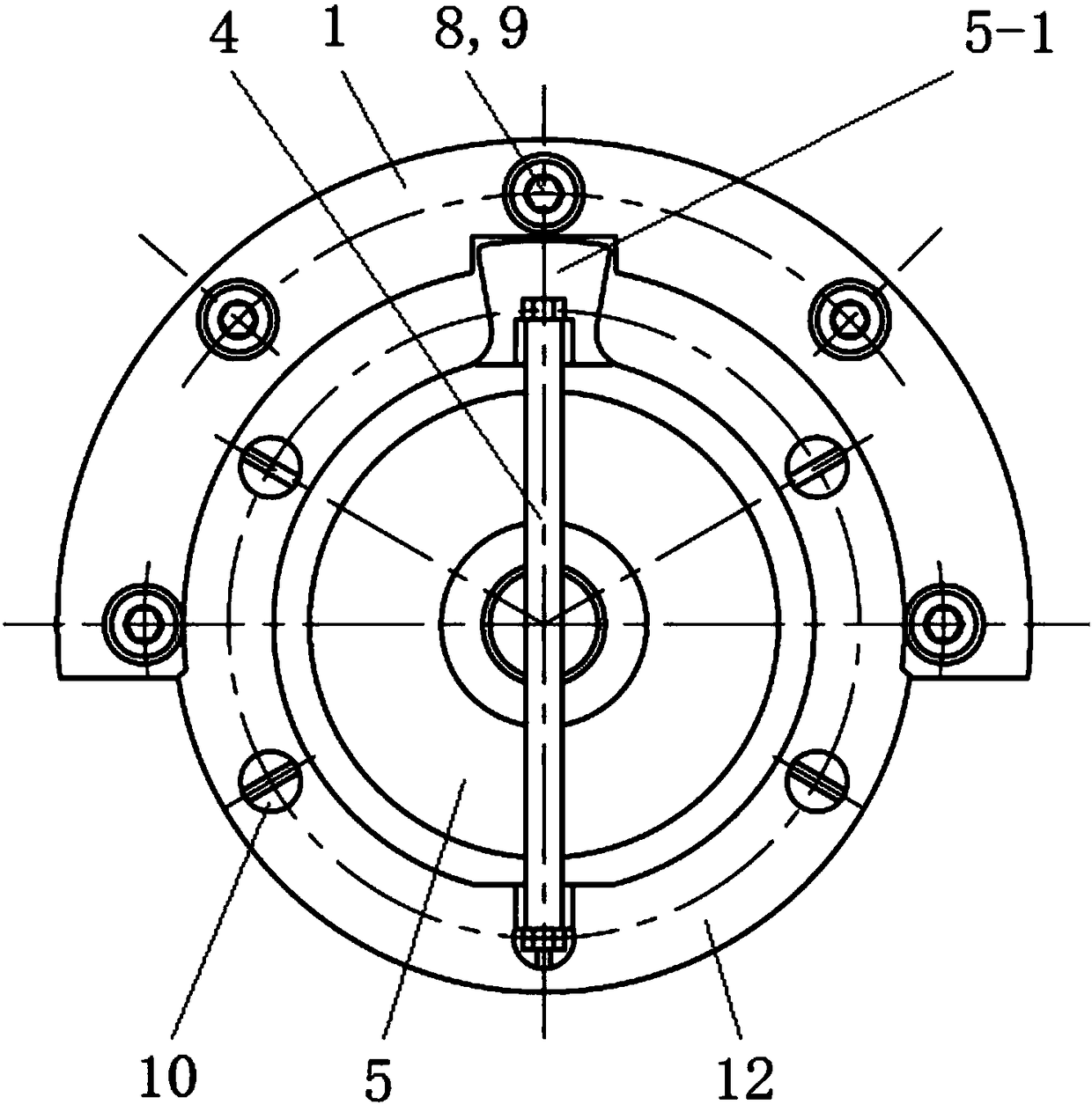

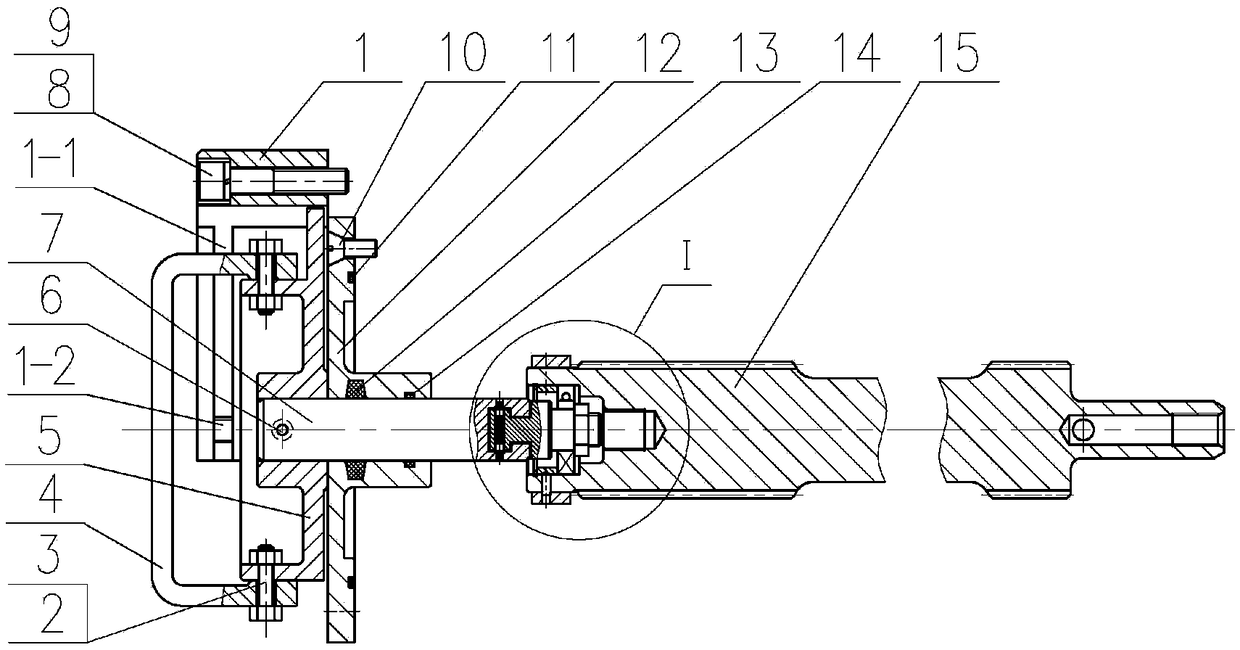

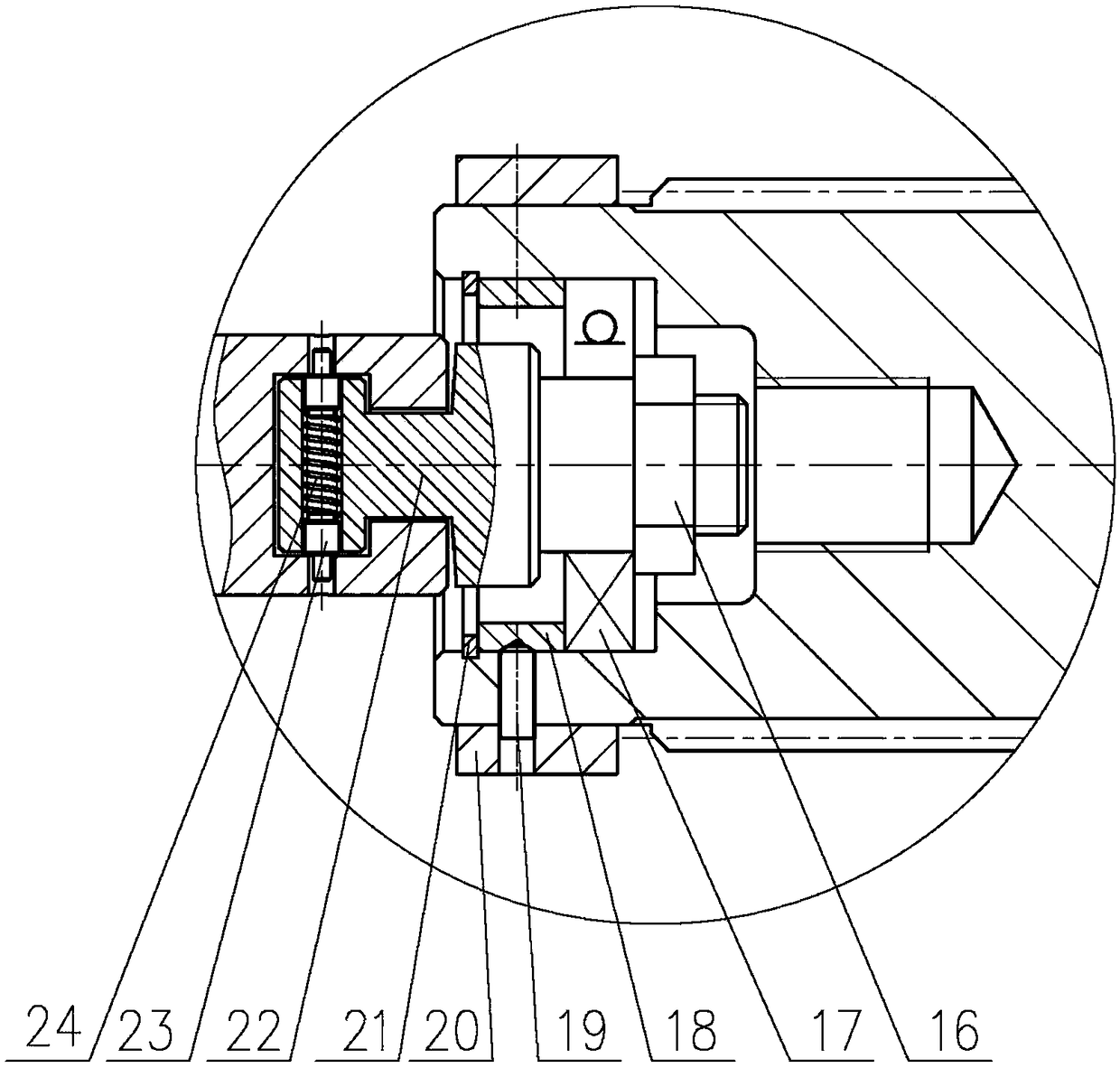

[0025] The invention discloses a flexible shock-absorbing clutch mechanism (hereinafter referred to as the clutch mechanism), such as figure 1 , 2 , 3, including handle 4, handle base 5, end cap 12, push-pull rod and flexible shaft 15. The push-pull rod includes a first push-pull rod 7 and a second push-pull rod 22, the rear end of the first push-pull rod is flexibly connected to the front end of the second push-pull rod, and the first push-pull rod passes through the end cover and is coaxially slidably connected with the end cover. Of course, when the handle is rotated, the first push-pull rod can also rotate relative to the end cover. The handle base is located in front of the end cover, and is fixedly connected to the front part of the first push-pull rod, the handle is fixed on the handle base, and the rear end of the second push-pull rod is connected to the flexible The front end of the shaft is coaxially rotatably connected, specifically axially fixed and circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com