An Intensive Locking Multi-mode Hydraulic Variable Valve Drive System

A drive system, locking technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., to achieve the effect of improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

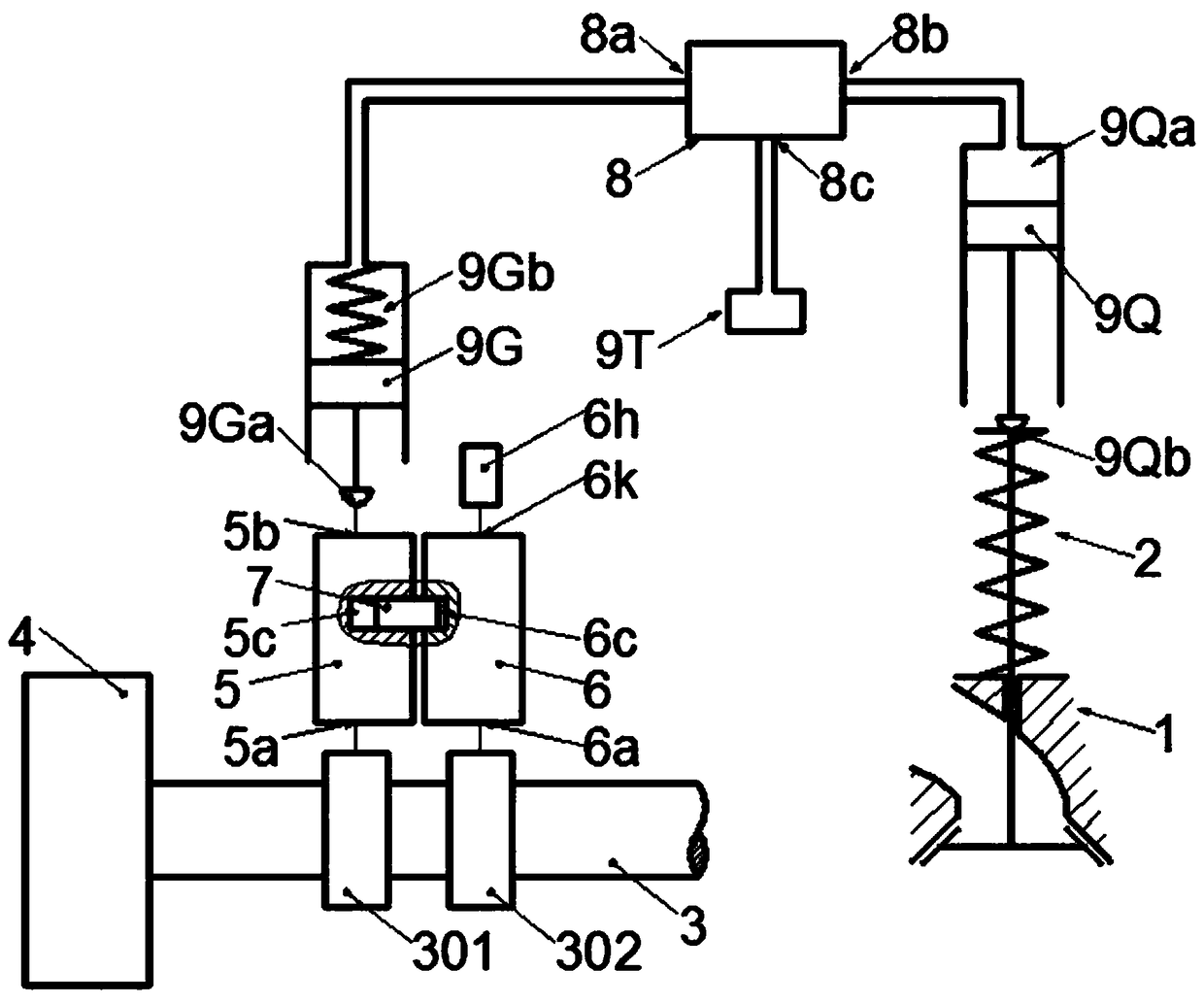

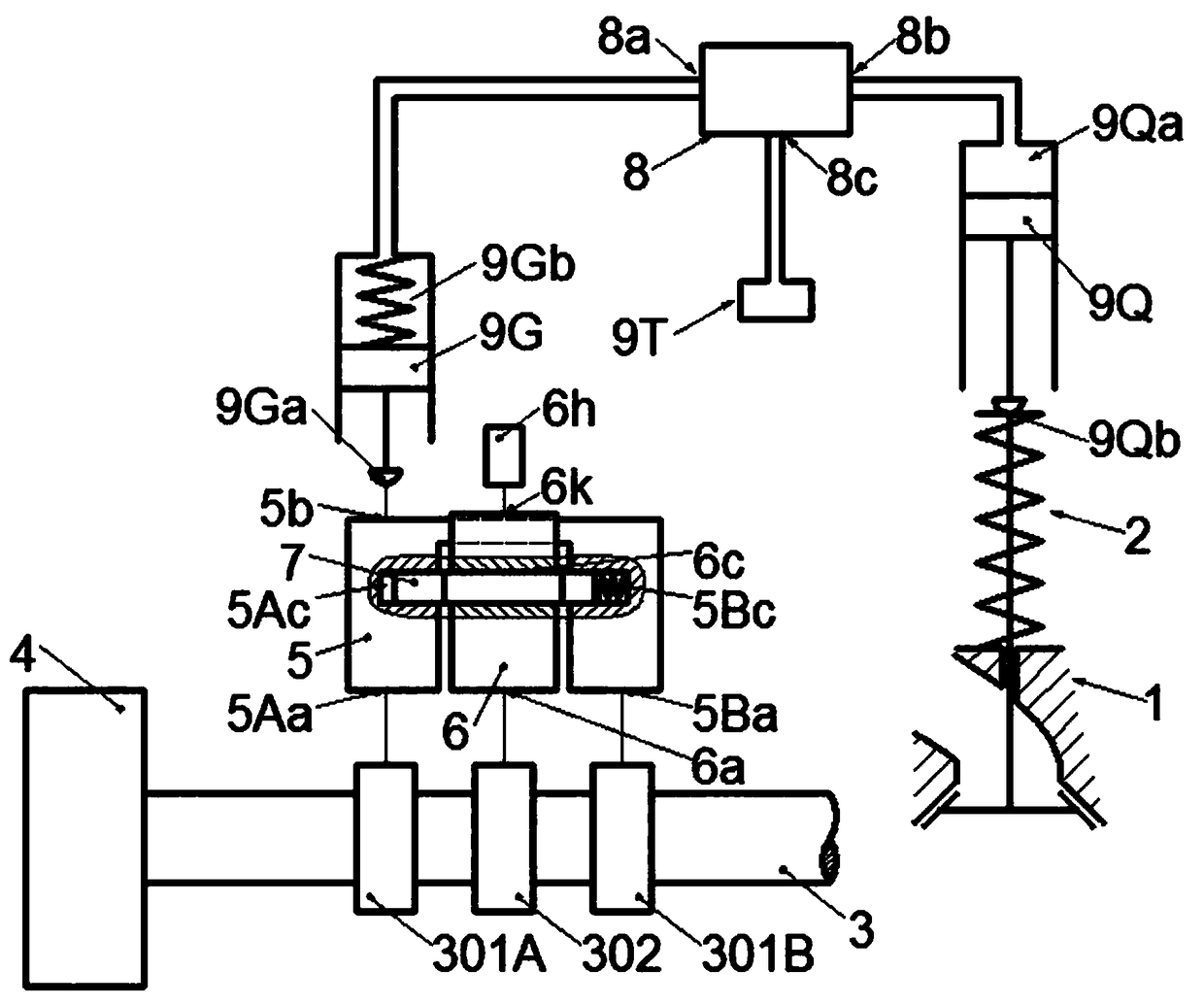

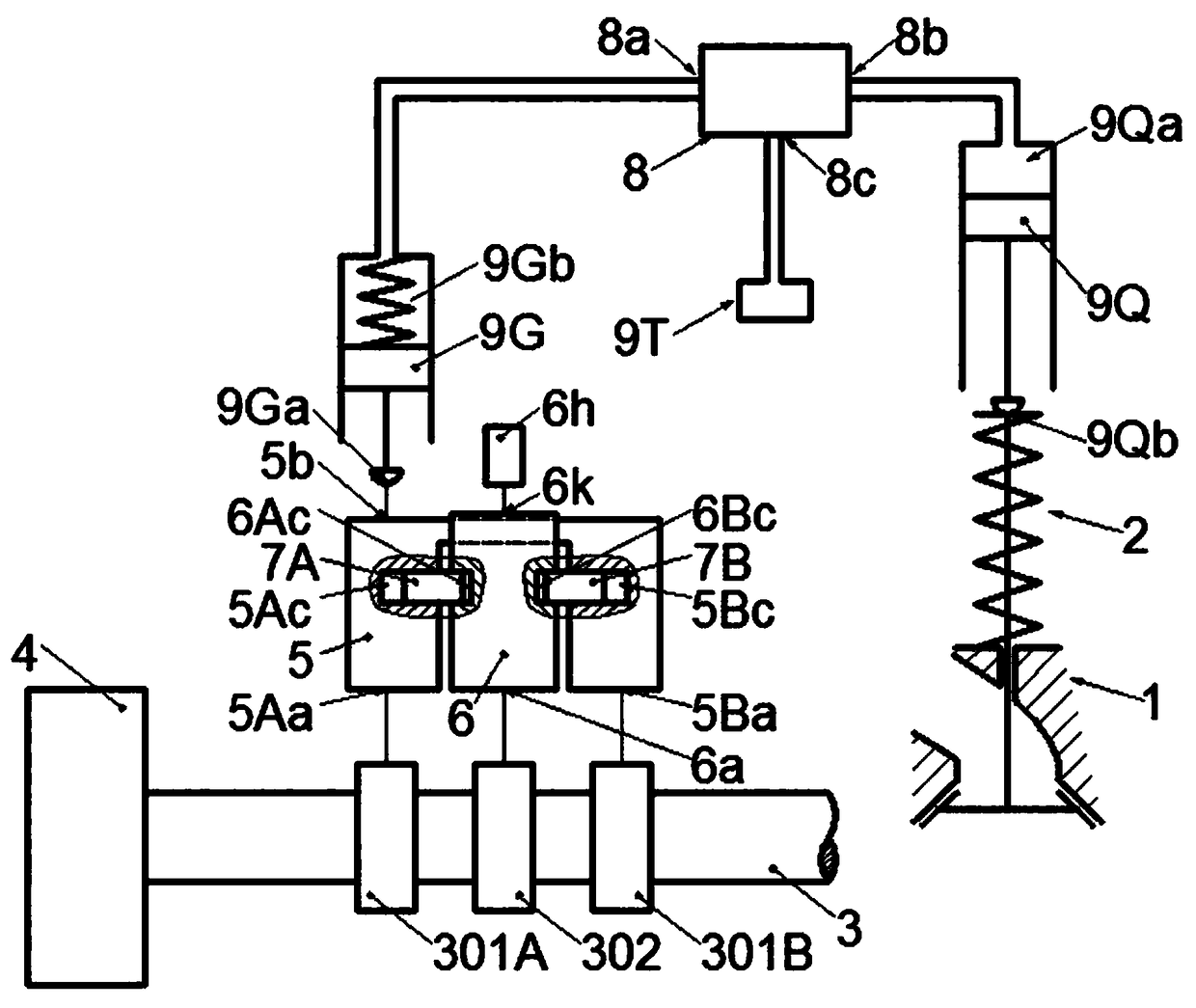

[0040] The invention relates to an intensive locking multi-mode hydraulic variable valve drive system. It includes valve driving mechanism 2, camshaft phase adjustment mechanism 4 on camshaft 3, camshaft 3, mode transmission mechanism 5, mode selection mechanism 6, mode switching mechanism 7, valve control mechanism 8, plunger oil supply 9G, piston driver 9Q and oil reservoir 9T. figure 1 It is a schematic diagram of an intensive lock-type multi-mode hydraulic variable valve drive system with double-cam drive, double-input, single-output, single-switching, single-valve operation, and single-regulation. The camshaft 3 is provided with a first cam 301 and a second cam 302 . The first cam 301 has one protrusion, and the second cam 302 has one protrusion or two protrusions. The projection of the second cam 302 having one projection has the same profile as the projection of the first cam 301, and the phase difference is 180° of camshaft rotation angle. The profiles of the two pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com