An Intensive Locking Multi-mode Variable Valve Drive System

A drive system, locking technology, applied in the direction of combustion engine, engine components, machine/engine, etc., to achieve high cost performance, optimized operation, and improved power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

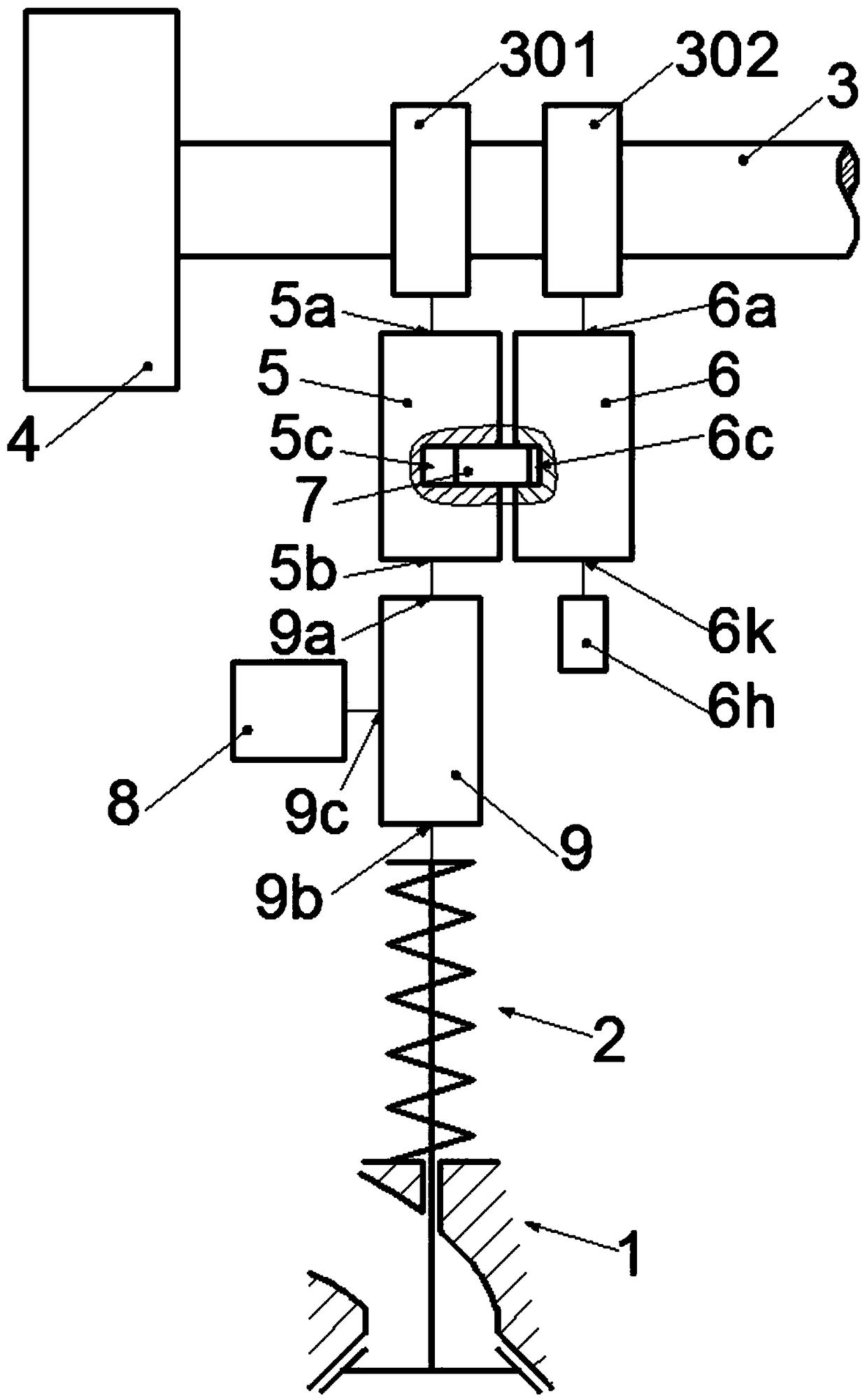

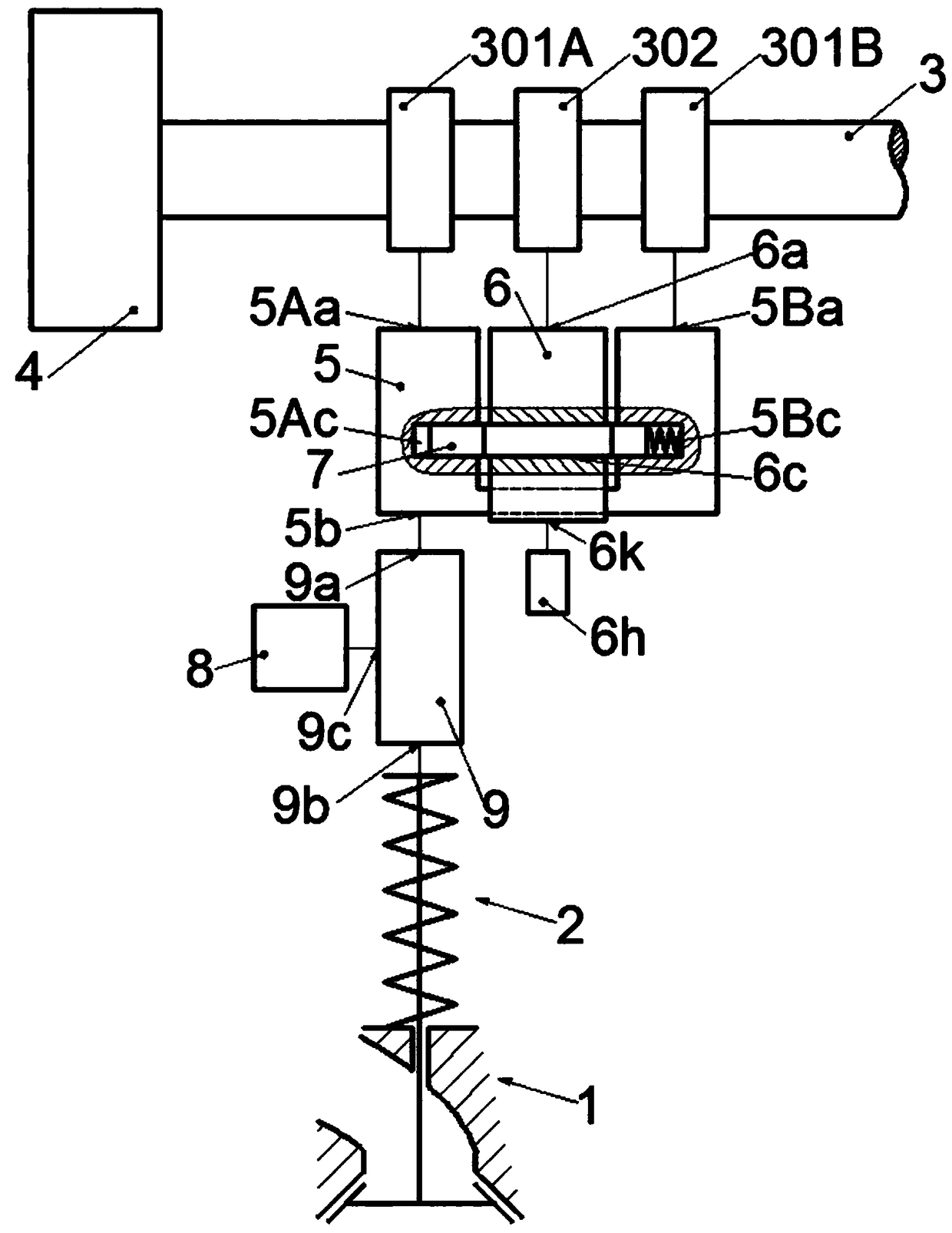

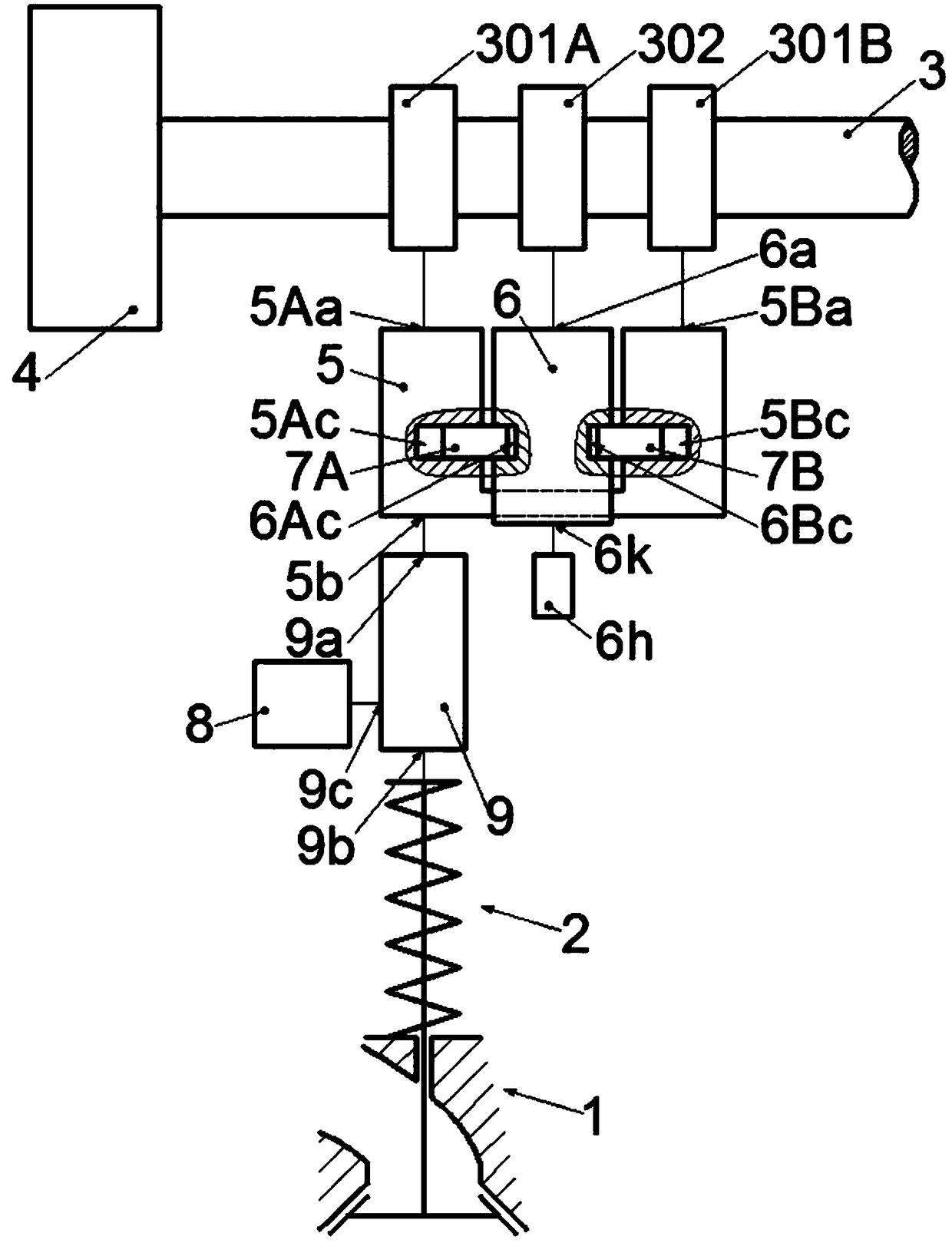

[0032] The invention relates to an intensive locking multi-mode variable valve drive system. It includes a valve driving mechanism 2 and a camshaft phase adjustment mechanism 4 arranged on the camshaft 3 . It also includes a camshaft 3 , a mode transmission mechanism 5 , a mode selection mechanism 6 , a mode switching mechanism 7 , a valve control mechanism 8 , and a valve adjustment mechanism 9 . figure 1It is a schematic diagram of an intensive lock-type multi-mode variable valve drive system with double-cam drive, double-input, single-output, single-switching, single-valve operation, and single-regulation. The camshaft 3 is provided with a first cam 301 and a second cam 302 . Since both the four-stroke driving mode and the four-stroke braking mode operate once every 720° of the crankshaft angle, the intake / exhaust valves are called the four-stroke mode; the two-stroke driving mode and the two-stroke braking mode both operate every 360° °The intake / exhaust valve operates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com