Non-leakage pressure compensated electro-proportional throttle valve

A pressure compensation, electric proportional technology, applied in the field of hydraulic valves, can solve the problems of unsustainable load, large leakage, non-pressure maintaining of valves, etc., and achieve the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

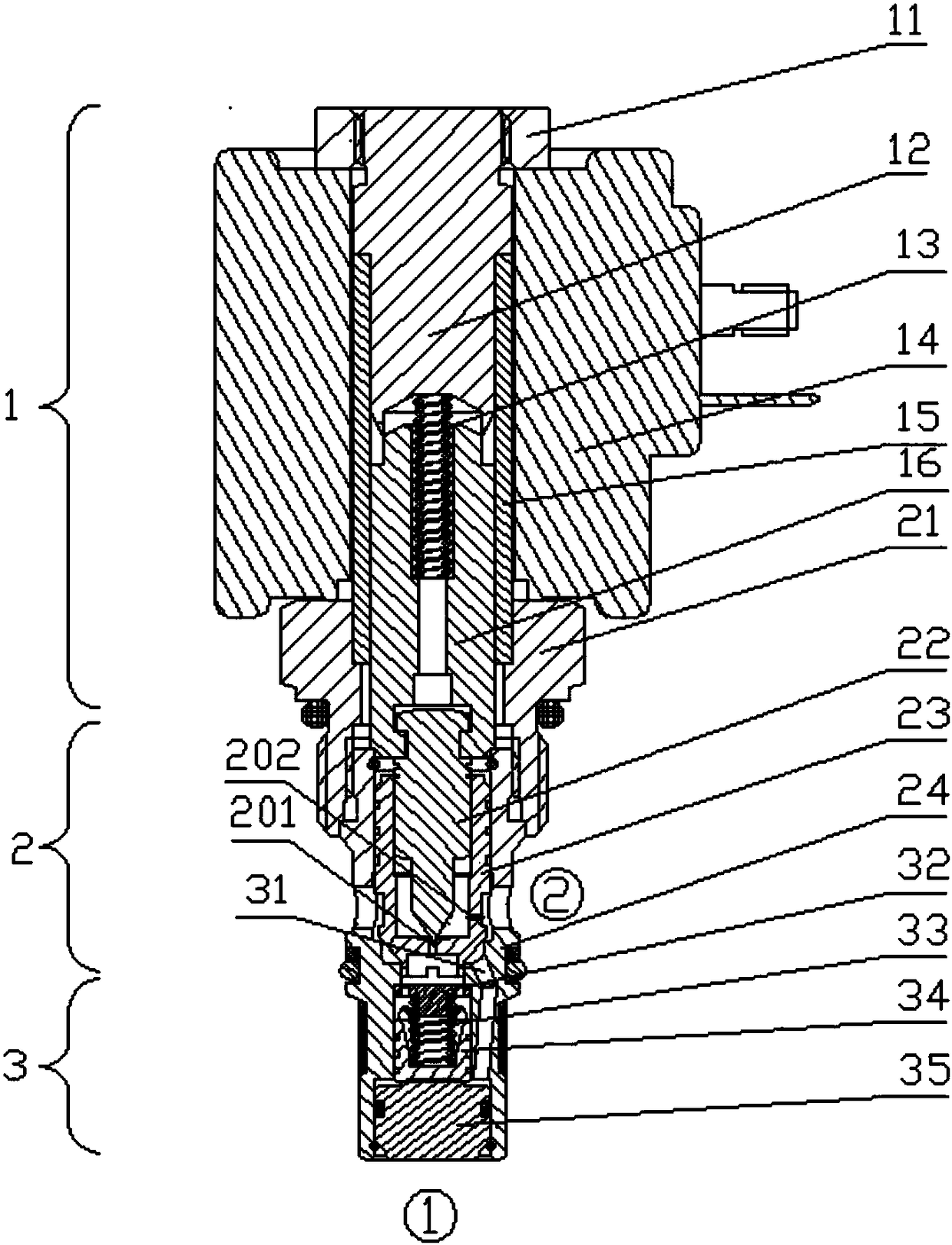

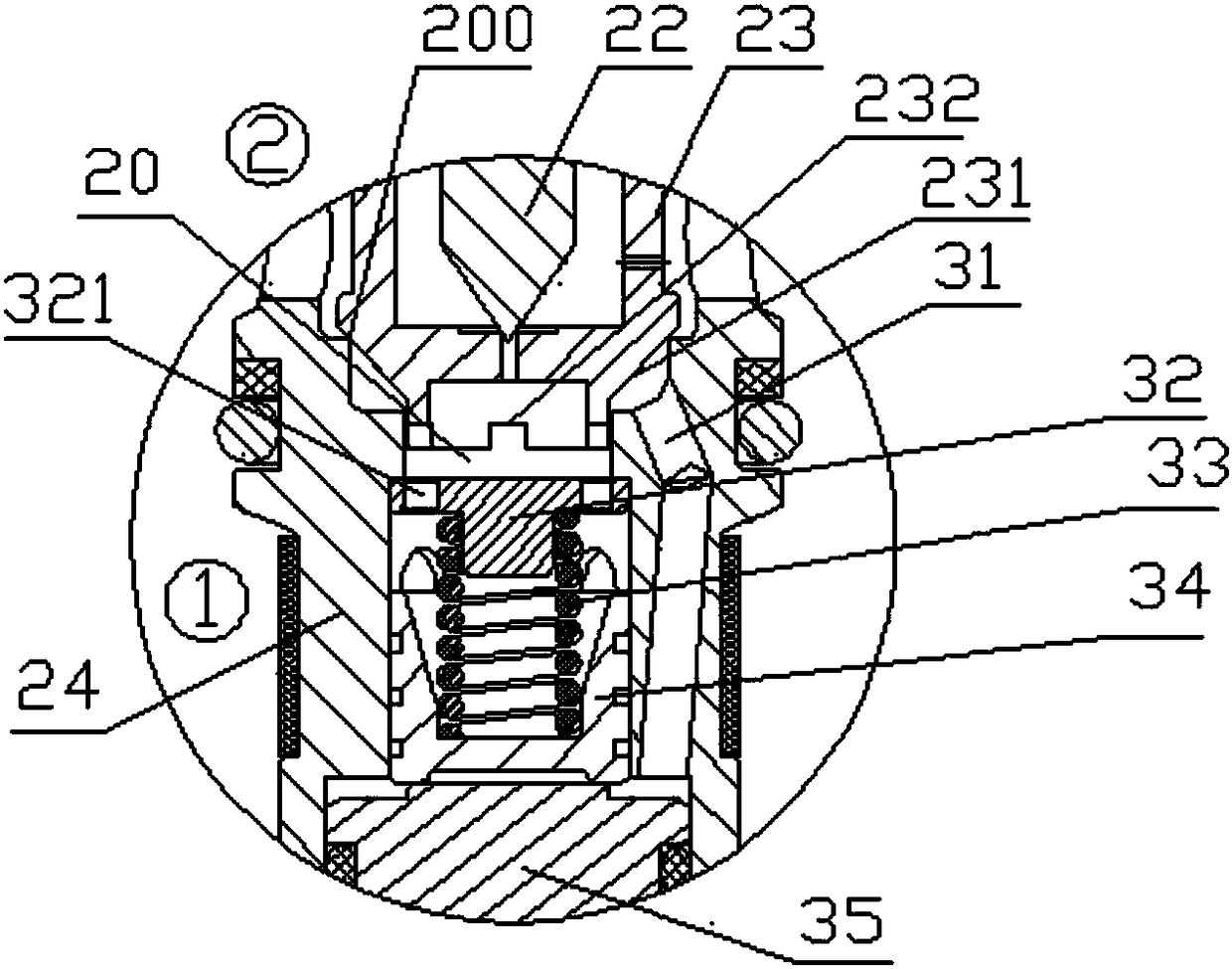

[0020] Such as figure 1 and figure 2 As shown, the non-leakage pressure-compensated electric proportional throttle valve includes proportional solenoid 1, main valve 2 and pressure compensator 3, which form a two-way non-leakage threaded cartridge valve, which can realize direction control and proportional flow adjustment Function, non-leakage function when fully closed, constant flow during work and many other functions.

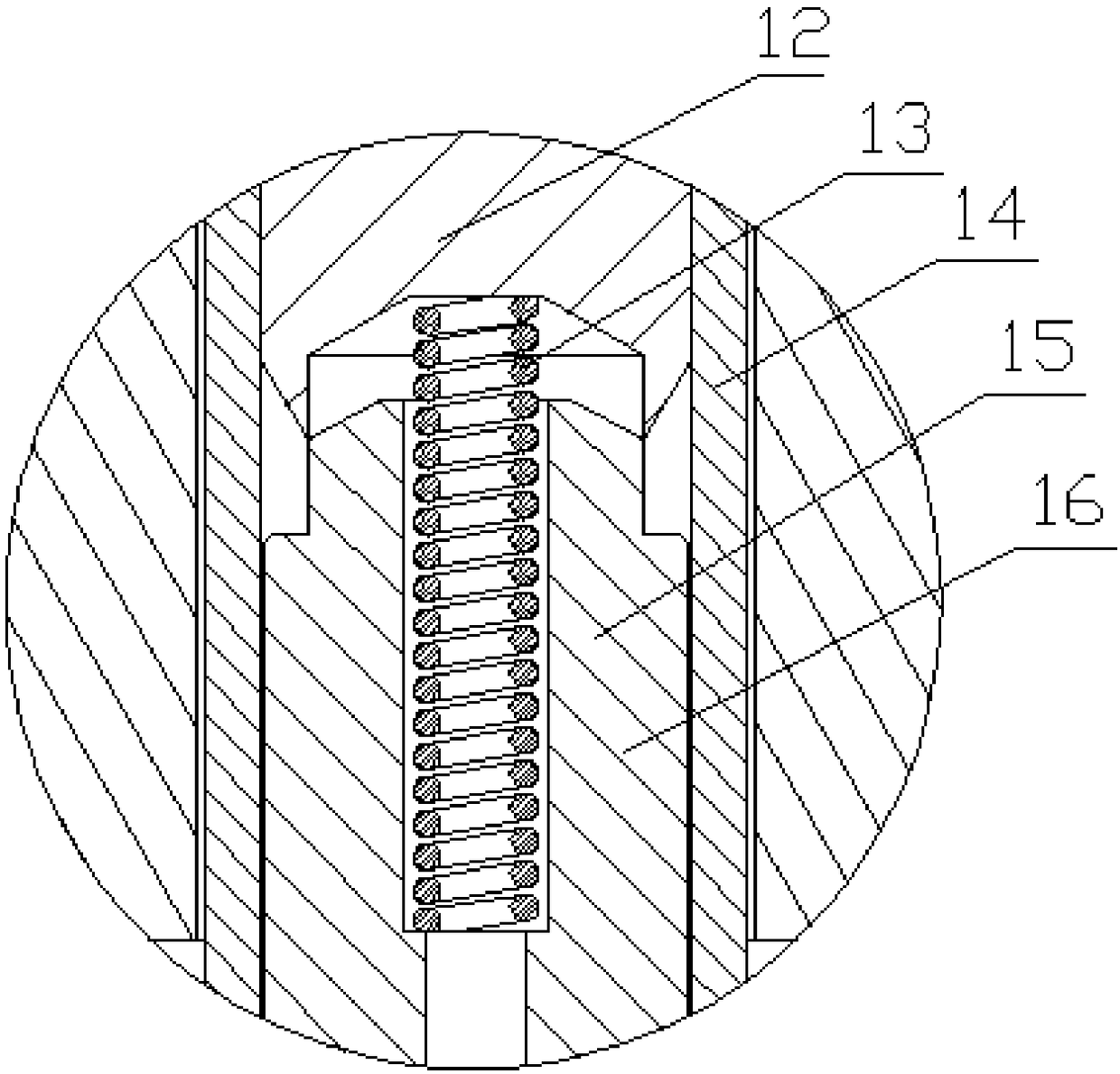

[0021] Among them, the proportional electromagnet 1 includes a magnetic isolation sleeve 15, a front end 21 located on the front side of the magnetic isolation sleeve 15 and connected to the main valve 2, a tail end 12 located on the rear side of the magnetic isolation sleeve, and an armature located inside the magnetic isolation sleeve. 16 and the first spring 13 that is located between the armature 16 and the tail to elastically press the armature forward, and the locking nut 11 locks and fixes the coil 14 on the magnetic isolation sleeve 15 . Tail 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com