A Dining Cart Using Directional Constant Pressure Difference to Purify Air

An air purification and differential pressure technology, applied in air treatment equipment, applications, household stoves, etc., can solve the problems of air pollution in restaurants, and create a dining environment for guests who cannot dine, so as to avoid air pollution and prevent pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

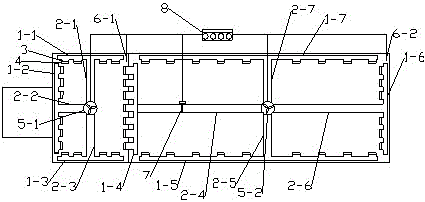

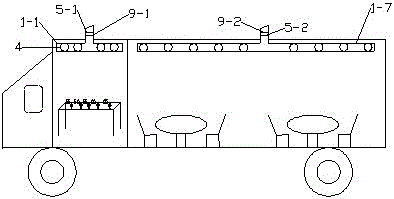

[0023] Embodiment 1: as attached figure 1 And attached figure 2 As shown, a dining car using directional constant pressure difference to realize air purification, its structure includes: 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7 respectively One, second, third, fourth, fifth, sixth and seventh static pressure chambers, 2-1, 2-2, 2-3, 2-4, 2-5, 2-6, 2-7 They are the first, second, third, fourth, fifth, sixth and seventh main air ducts, 3 is a small diameter filter, 4 is a branch air duct, 5-1, 5-2 are the first Fan and the second fan, 6-1, 6-2 are the first and second differential pressure gauges respectively, 7 is the valve switch, 8 is the control panel, 9-1, 9-2 are respectively the first and second largest Pipe diameter filter. The first, second and third static pressure chambers 1-1, 1-2 and 1-3 are respectively connected to the first Fan 5-1; the fourth, fifth, sixth and seventh static pressure chambers 1-4, 1-5, 1-6 and 1-7 pass through the fourth, fifth, sixth and seventh ...

Embodiment 2

[0025] Embodiment 2: as attached figure 1 And attached figure 2 As shown, a dining car using directional constant pressure difference to realize air purification, its structure includes: 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7 respectively One, second, third, fourth, fifth, sixth and seventh static pressure chambers, 2-1, 2-2, 2-3, 2-4, 2-5, 2-6, 2-7 They are the first, second, third, fourth, fifth, sixth and seventh main air ducts, 3 is a small diameter filter, 4 is a branch air duct, 5-1, 5-2 are the first Fan and the second fan, 6-1, 6-2 are the first and second differential pressure gauges respectively, 7 is the valve switch, 8 is the control panel, 9-1, 9-2 are the first and second largest Pipe diameter filter. The first, second and third static pressure chambers 1-1, 1-2 and 1-3 are respectively connected to the first Fan 5-1; the fourth, fifth, sixth and seventh static pressure chambers 1-4, 1-5, 1-6 and 1-7 pass through the fourth, fifth, sixth and seventh main air ducts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com