Bridge pipeline supporting structure

A pipeline support and bridge technology, applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, devices to prevent contact with live contacts, etc., can solve the problems of pipeline maintenance or moving fixed positions, difficult to remove, etc., to achieve convenient and automatic Controlled unlocking, avoiding the risk of electric shock, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

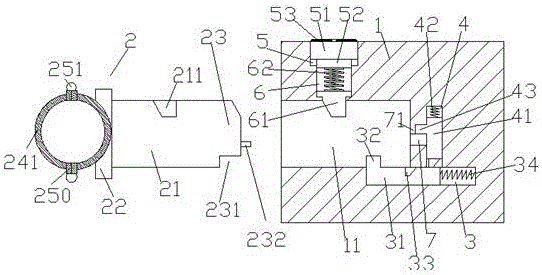

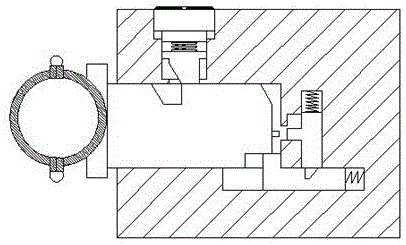

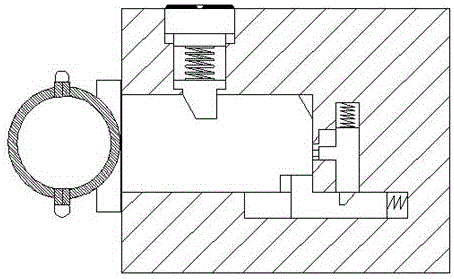

[0023] like Figure 1-Figure 5 As shown, a bridge pipeline support structure of the present invention includes a support base 1 and a support member 2 cooperating with the support base 1, and the support member 2 is composed of a support ring 241, a fastening plate 22 and a support rod 21. , the support ring 241 is fixedly arranged on the left side of the fastening plate 22, and the ring body of the support ring 241 is symmetrically arranged with two outwardly extending ends 250, and the ends 250 are provided with There is a warning light 251, and the right side of the fastening plate 22 is fixedly connected with a support rod 21, and the end surface of the support rod 21 away from the fastening plate 22 is provided with a beveled portion 23, and the beveled portion 23 is connected to the The top of the support rod 21 between the fastening plates 22 is provided with a left insertion slot 211, and the support seat 1 is provided with a plug-in compartment 11 for cooperating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com