An integrated sand control and grease storage missile linkage locking device

A locking device, sand prevention and grease storage technology, applied in the direction of the launch device, etc., can solve the problems of poor coaxiality between multiple screws, high coaxiality requirements, and laborious locking and stagnation, etc., to reduce the mechanism Failure rate, good adaptability, and the effect of preventing rain erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

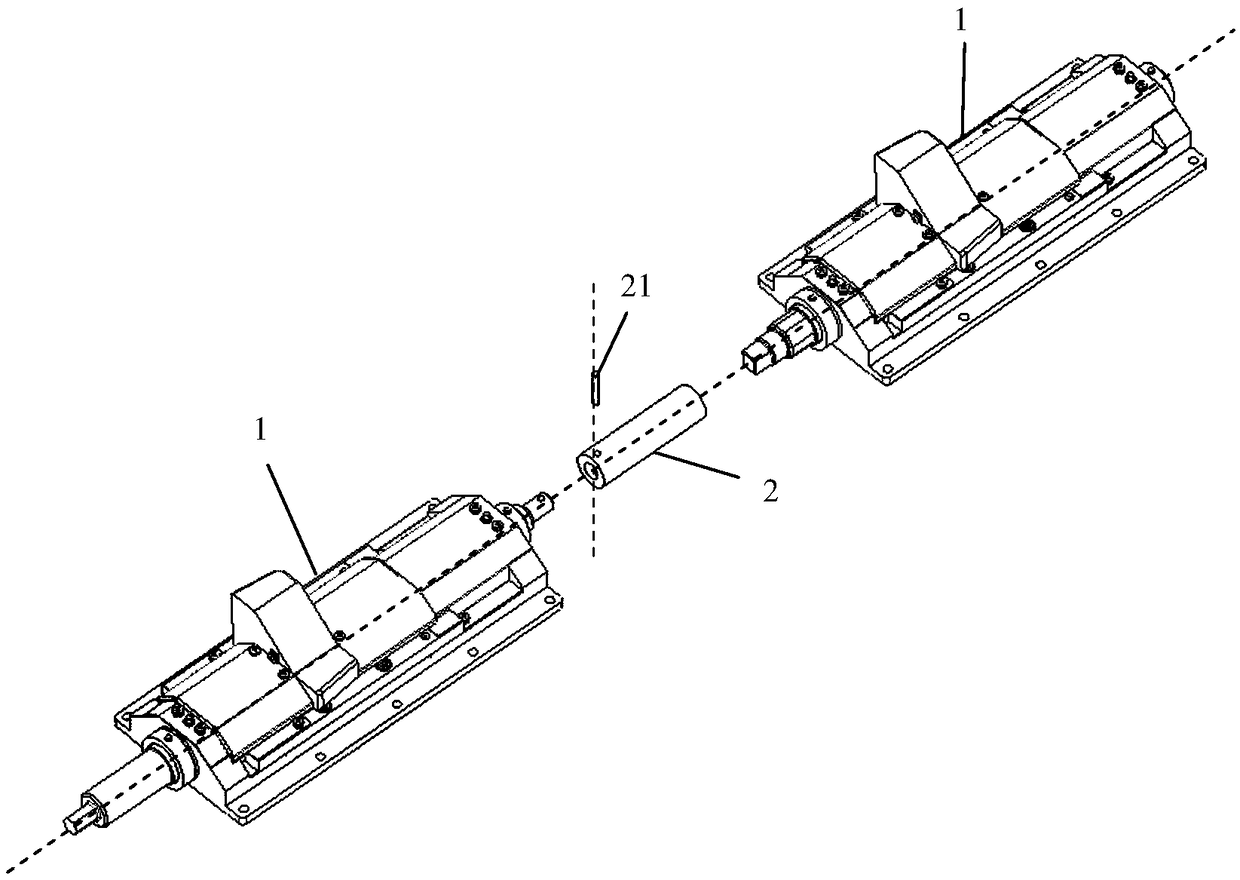

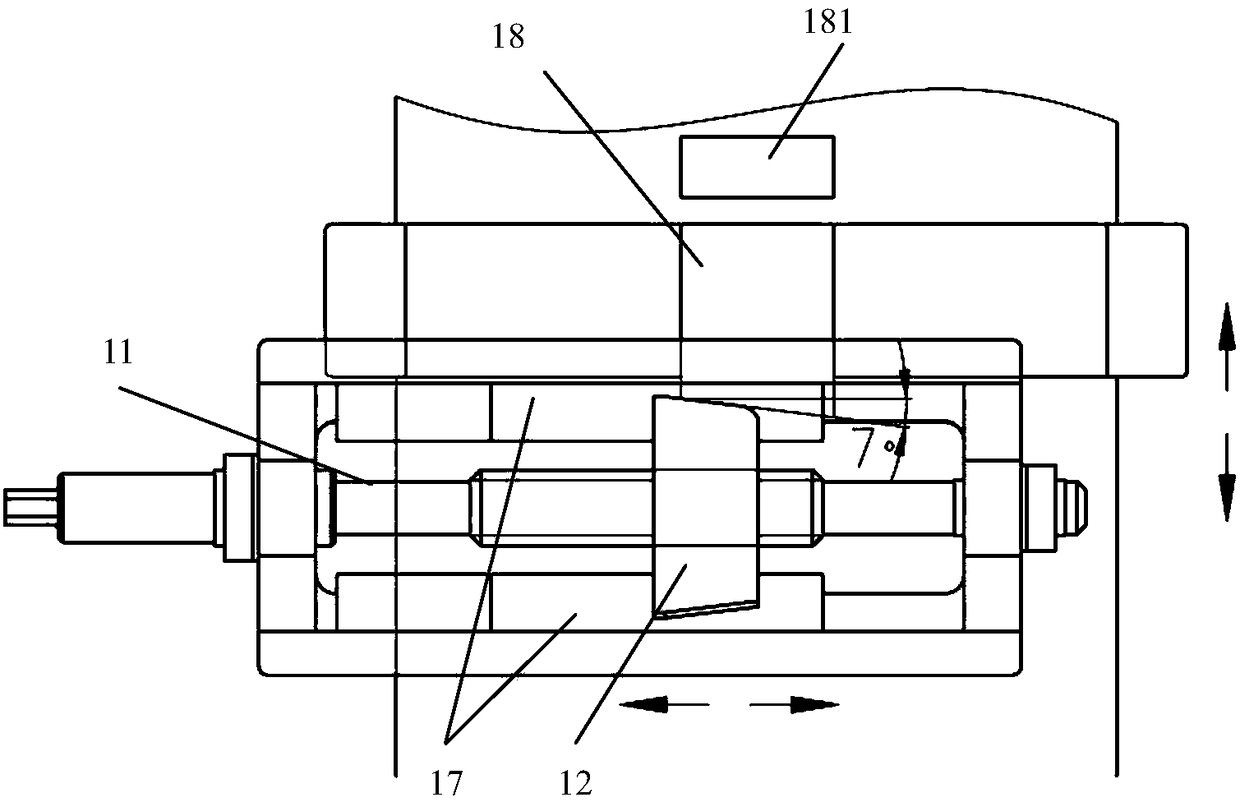

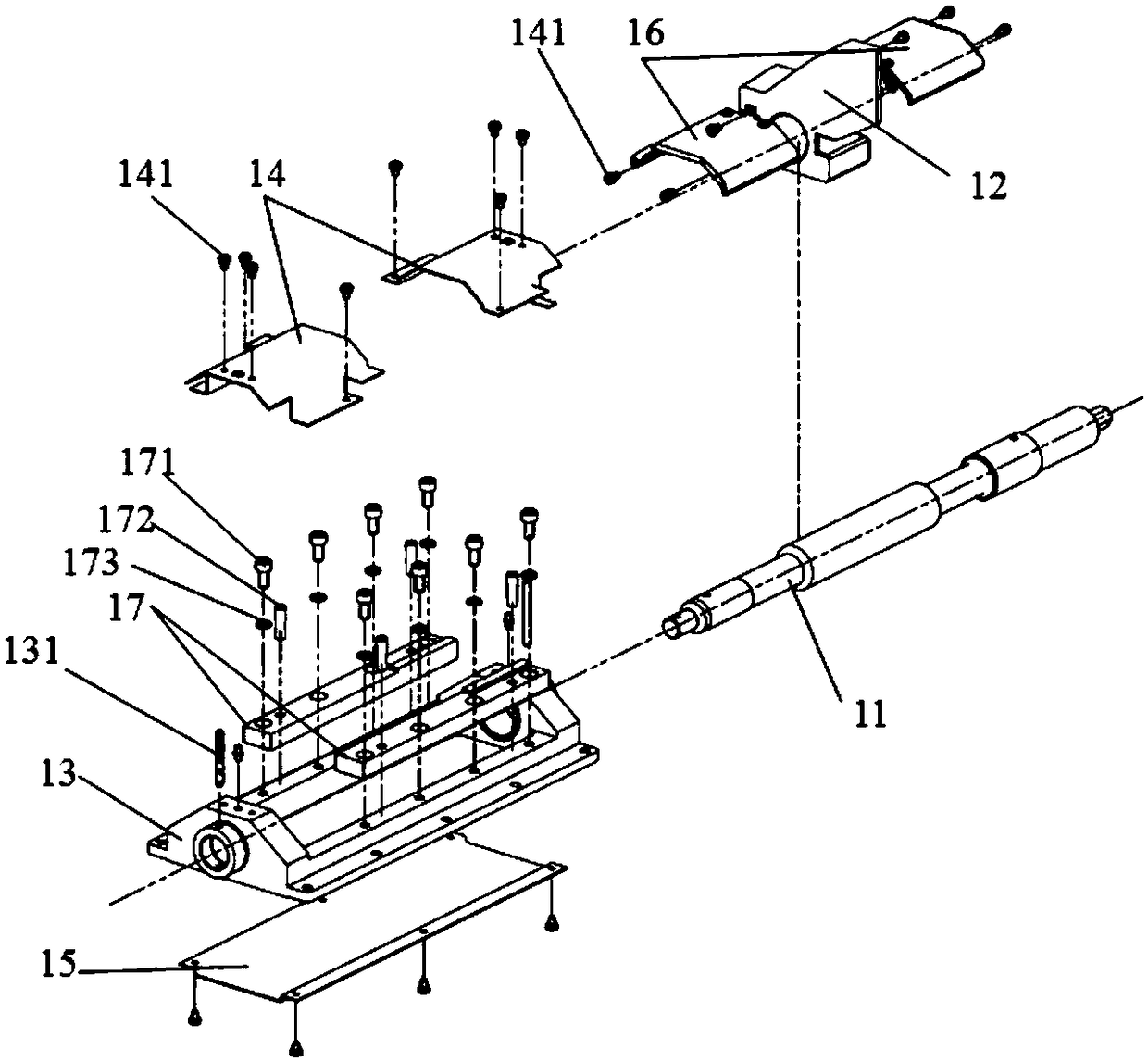

[0034] Such as figure 1 , 5 As shown in the figure, an integrated sand control and grease storage missile linkage locking device is suitable for ground and ship surface missile weapon system storage, transportation and launching devices. The linkage locking device includes a plurality of sequentially connected locking units 1, and each lock Tight unit 1 contains respectively: such as Figure 1~3 As shown, the base 13; the lead screw 11 is rotatably fixed in the base 13, and its two ends protrude from the two ends of the base 13 respectively and are connected with the corresponding ends of the lead screw 11 of the adjacent locking unit 1, The lead screw 11 has an external thread, the lead screw 11 is covered with a briquetting block 12, and the briquetting block 12 is provided with an internal thread, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com