A measuring device and method for capacitive sound

A technology for measuring devices and measuring methods, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of subjective and environmental noise, inaccurate methods for measuring capacitive sound, etc., and improve measurement accuracy and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

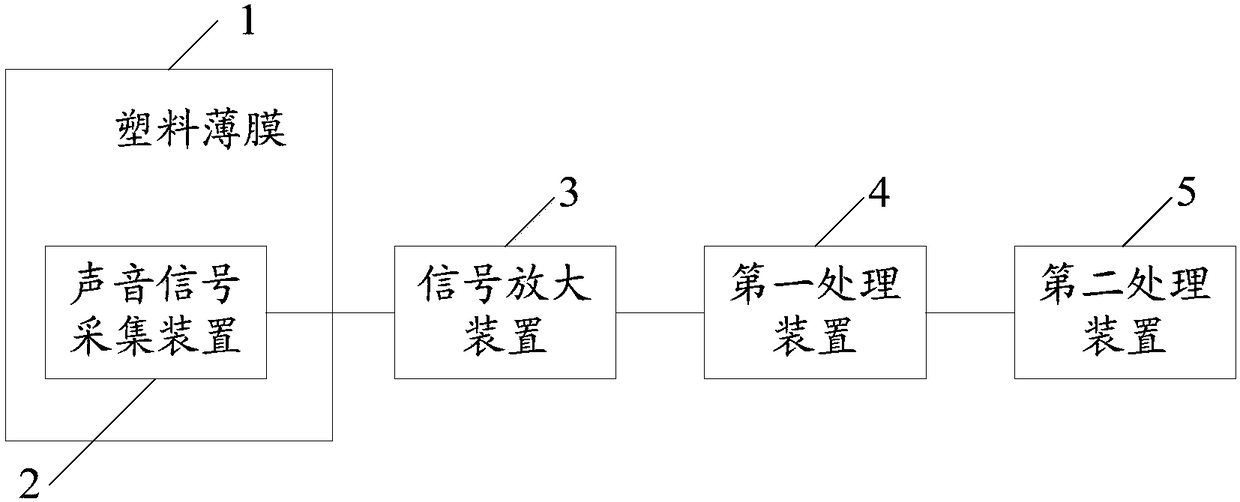

[0023] The first embodiment of the present invention provides a capacitive sound measuring device, which is applied to a terminal, and the capacitive vibration on the main board of the terminal generates the capacitive sound around the receiver of the terminal. The measuring device includes:

[0024] Plastic film 1, the plastic film 1 is covered on the receiver of the terminal; wherein, the capacitive vibration on the main board of the terminal drives the air in the plastic film to vibrate to generate vibration sound, and the vibration sound is the same as the capacitive sound.

[0025] The ceramic capacitor of the terminal has a piezoelectric effect due to the stacked structure. During a call, the voltage at both ends of the capacitor changes due to the large power draw, causing mechanical deformation of the capacitor, which drives the terminal motherboard to vibrate, and generates capacitance sound. The capacitive sound generated by the vibration of the main board of the term...

no. 2 example

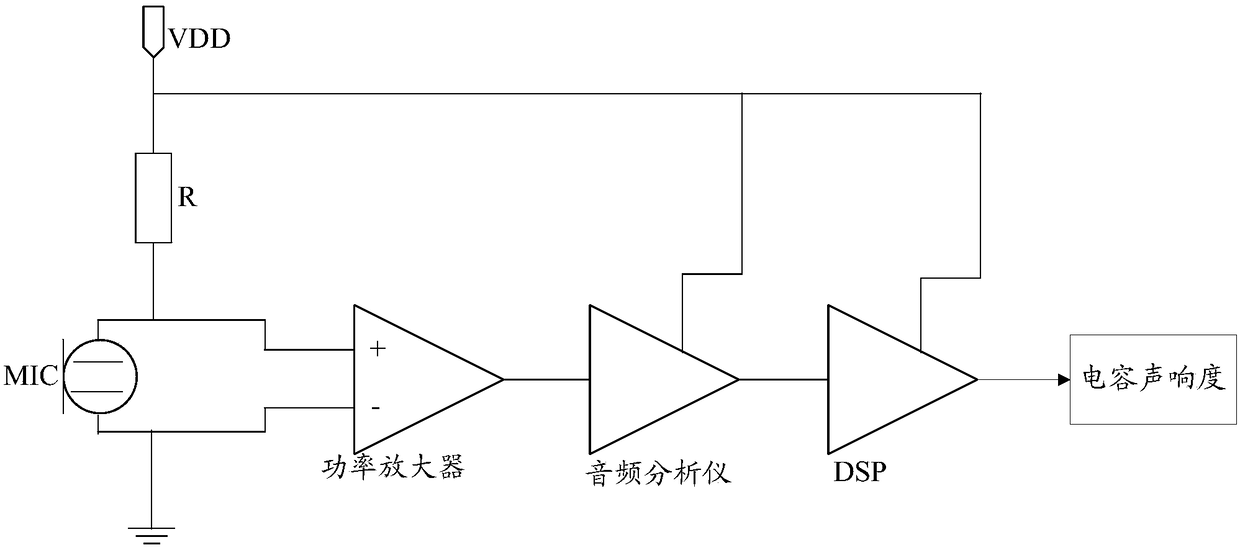

[0036] like figure 2 As shown, the second embodiment of the present invention provides a measuring device for capacitive sound, which includes:

[0037] Plastic film 1, the plastic film 1 is covered on the receiver of the terminal; wherein, the capacitive vibration on the main board of the terminal drives the air in the plastic film to vibrate to generate vibration sound, and the vibration sound is the same as the capacitive sound.

[0038] The ceramic capacitor of the terminal has a piezoelectric effect due to the stacked structure. During a call, the voltage at both ends of the capacitor changes due to the large power draw, causing mechanical deformation of the capacitor, which drives the terminal motherboard to vibrate, and generates capacitance sound. The capacitive sound generated by the vibration of the main board of the terminal is concentrated around the receiver, so in the embodiment of the present invention, a plastic film is used to cover the receiver of the termin...

no. 3 example

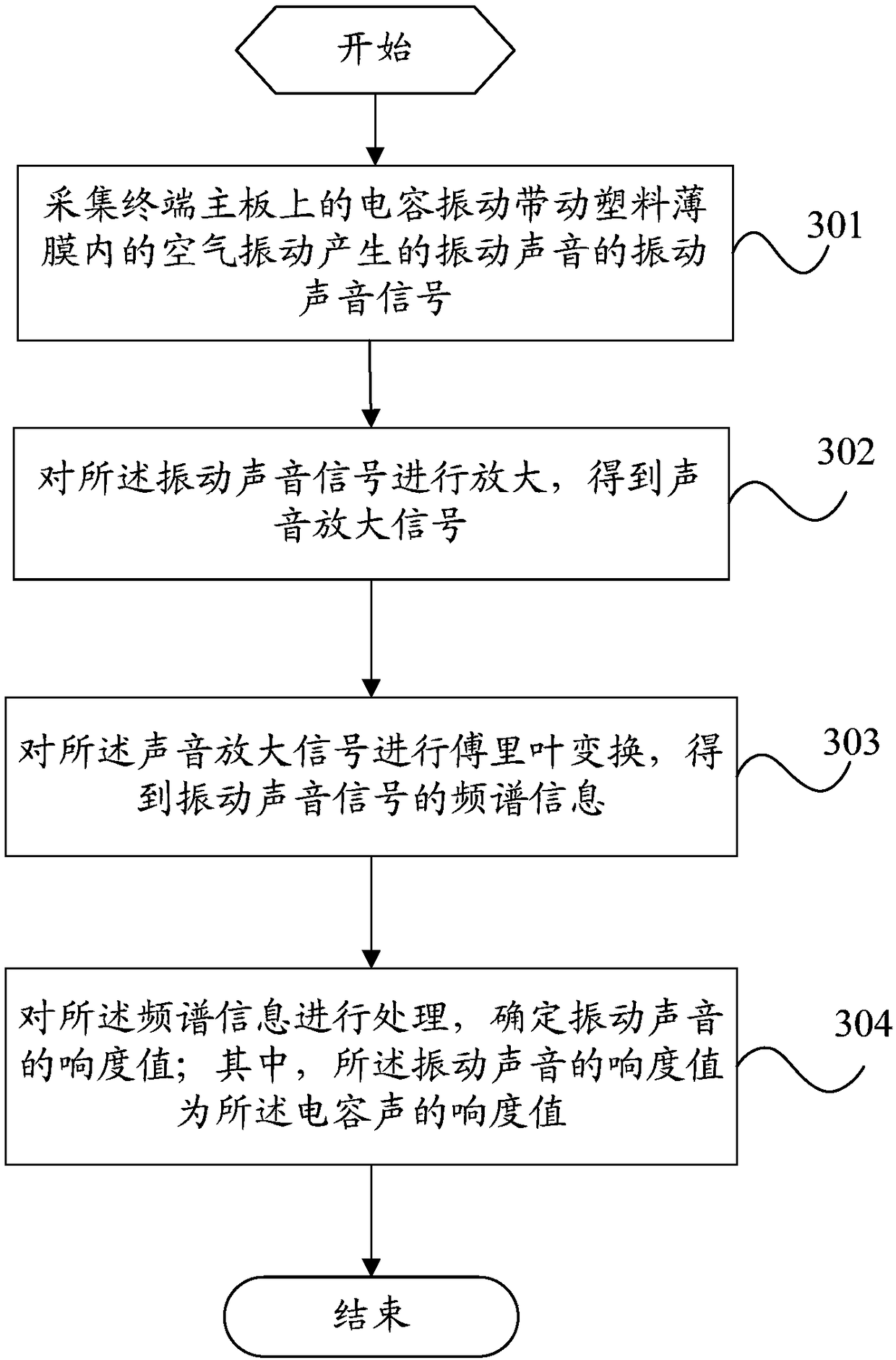

[0055] Such as image 3 As shown, the third embodiment of the present invention provides a method for measuring capacitive sound, the measuring method is applied to the measuring device for capacitive sound as described above, and the measuring method includes:

[0056] Step 301 , collecting a vibration sound signal of a vibration sound generated by vibration of air in a plastic film driven by capacitive vibration on the main board of the terminal.

[0057] In this step, the ceramic capacitor of the terminal has a piezoelectric effect due to the laminated structure. During a call, the voltage at both ends of the capacitor changes due to the large power draw, causing mechanical deformation of the capacitor, which drives the terminal motherboard to vibrate, and generates capacitive sound. The capacitive sound generated by the vibration of the main board of the terminal is concentrated around the receiver, so in the embodiment of the present invention, a plastic film is used to c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap