Wind tunnel test model assembly and disassembly assistance system

A wind tunnel test and auxiliary system technology, applied in the field of aerodynamics, can solve the problems of reducing the assembly accuracy of each part of the model, damage to the surface of the model and screw holes, difficulty in assembly and disassembly of the model, etc., to achieve automatic operation and simple appearance. , the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

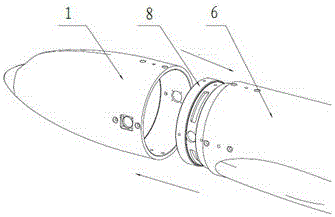

[0035] Such as figure 1 As shown, the test model consists of two parts, one is the fixed model part, the other is the movable model part, the connection part on the fixed model part is the mouth section, in order to ensure the integrity of the test model when doing the test, the movable model needs to be The component is fixedly connected with the fixed model component. However, the traditional method is like the operation described in the background art, but it will bring various adverse consequences, resulting in a decrease in test accuracy.

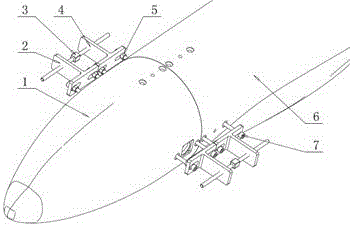

[0036] Such as figure 2 As shown, in order to solve the problem, this scheme provides a set of auxiliary tools for fast and easy connection of fixed model parts and movable model parts. Fixing holes are respectively arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com