Equipment for detecting durability of castors of office chair

A technology for testing equipment and durability, which is applied in the field of office chair caster durability testing equipment, can solve problems such as the inability to ensure the consistent placement of counterweights, the inconvenient connection between the load-bearing box and the air pressure rod, and the impact on the consistency of test results. Prevent gravity from being loaded accurately, improve detection efficiency and operation convenience, and facilitate counterweight loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

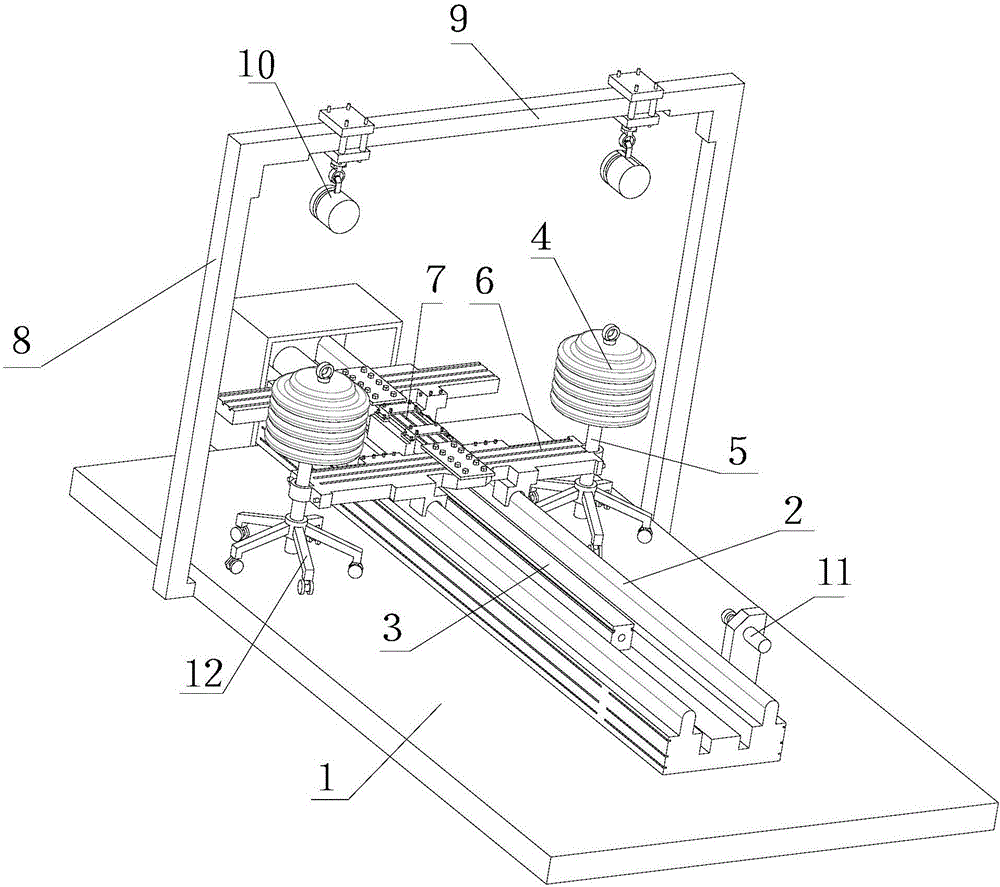

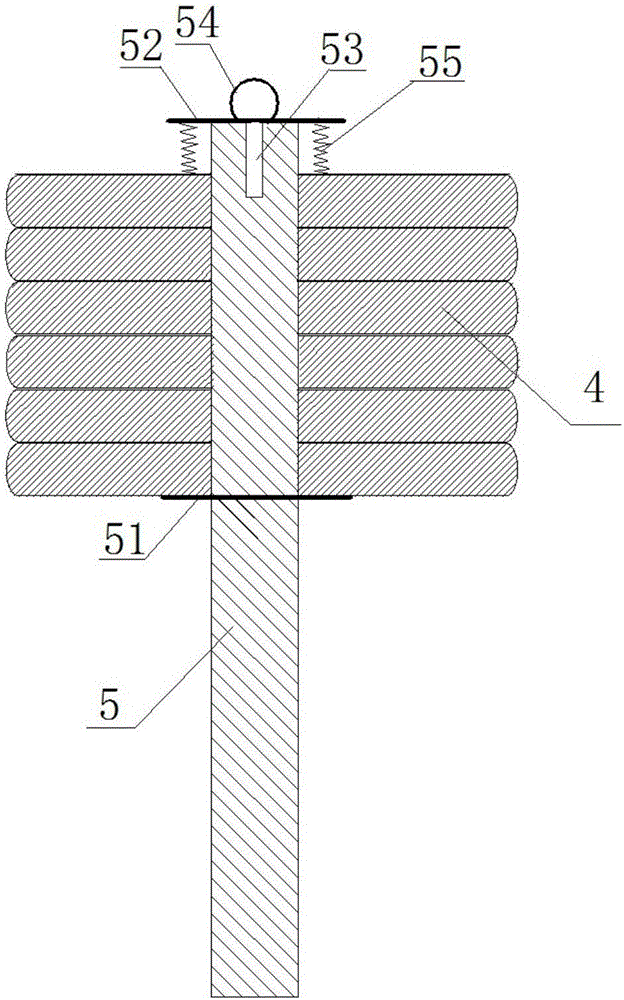

[0029] A kind of office chair caster durability testing equipment, such as figure 1 As shown, it includes a platform 1, a slide rail 2 arranged on the platform 1, a transmission arm slidingly connected with the slide rail 2, a driver 3 for driving the transmission arm to reciprocate along the slide rail 2, and a controller (controller) connected to the driver 3 in communication. not shown in the figure) and the counterweight mechanism connected with the transmission arm, the present embodiment selects a linear motor as the driver 3, and sets the transmission arm displacement limiter 11 on the slide rail 2, and the counterweight mechanism includes a counterweight 4 And the counterweight bar 5, the counterweight bar 5 is connected with the counterweight 4, the bottom of the counterweight bar 5 protrudes from the bottom of the counterweight 4, and during work, the lower part of the counterweight bar 5 and the transmission arm slide in the vertical direction Connect, the bottom of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap