Freeze-thaw thermal cycle triaxial seepage multifunctional pressure chamber for geotechnical materials

A geotechnical material and thermal cycle technology, which is applied in soil material testing, material inspection products, etc., can solve problems such as the inability to control the test temperature and the inability to perform seepage testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the invention will be further described:

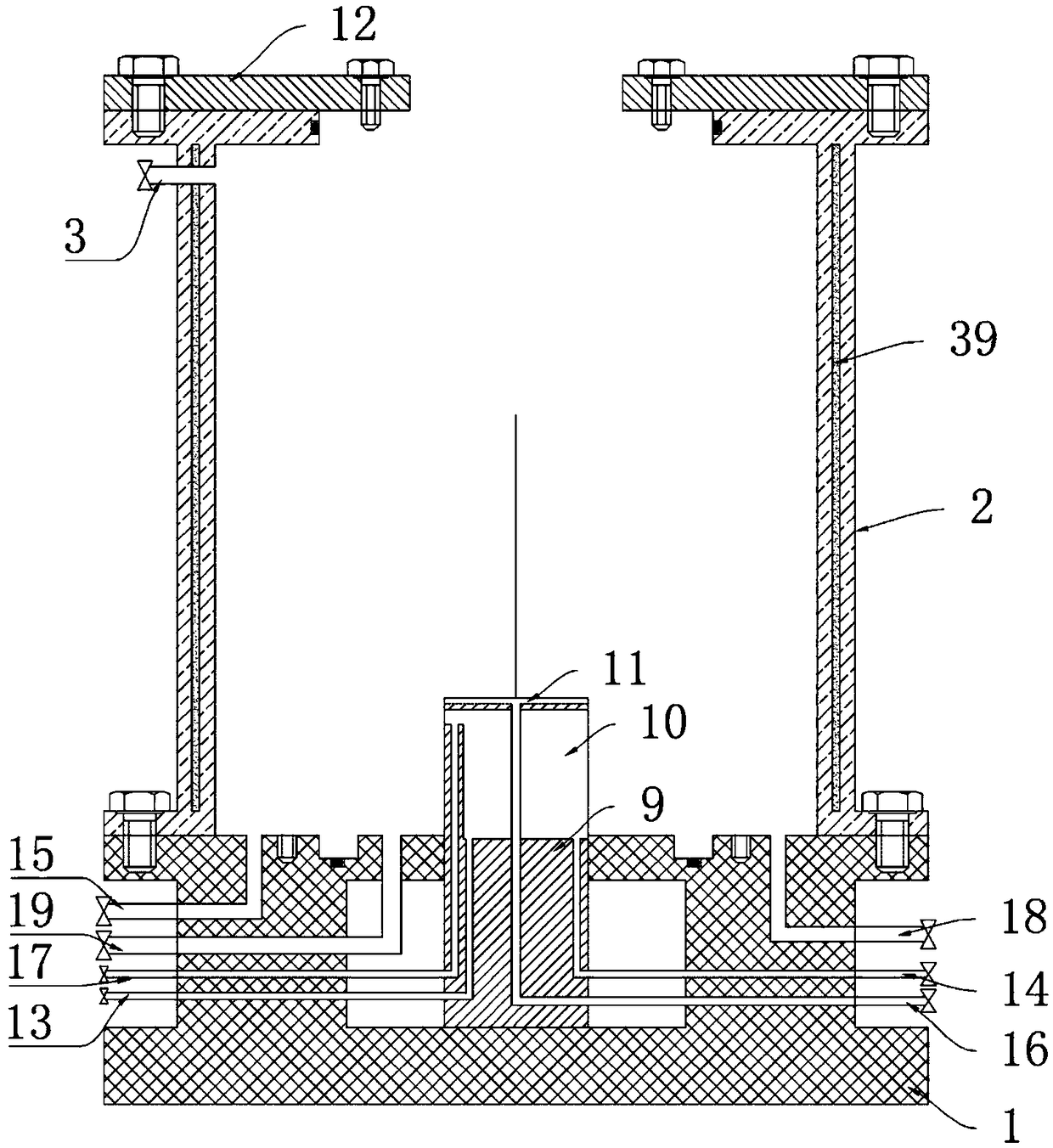

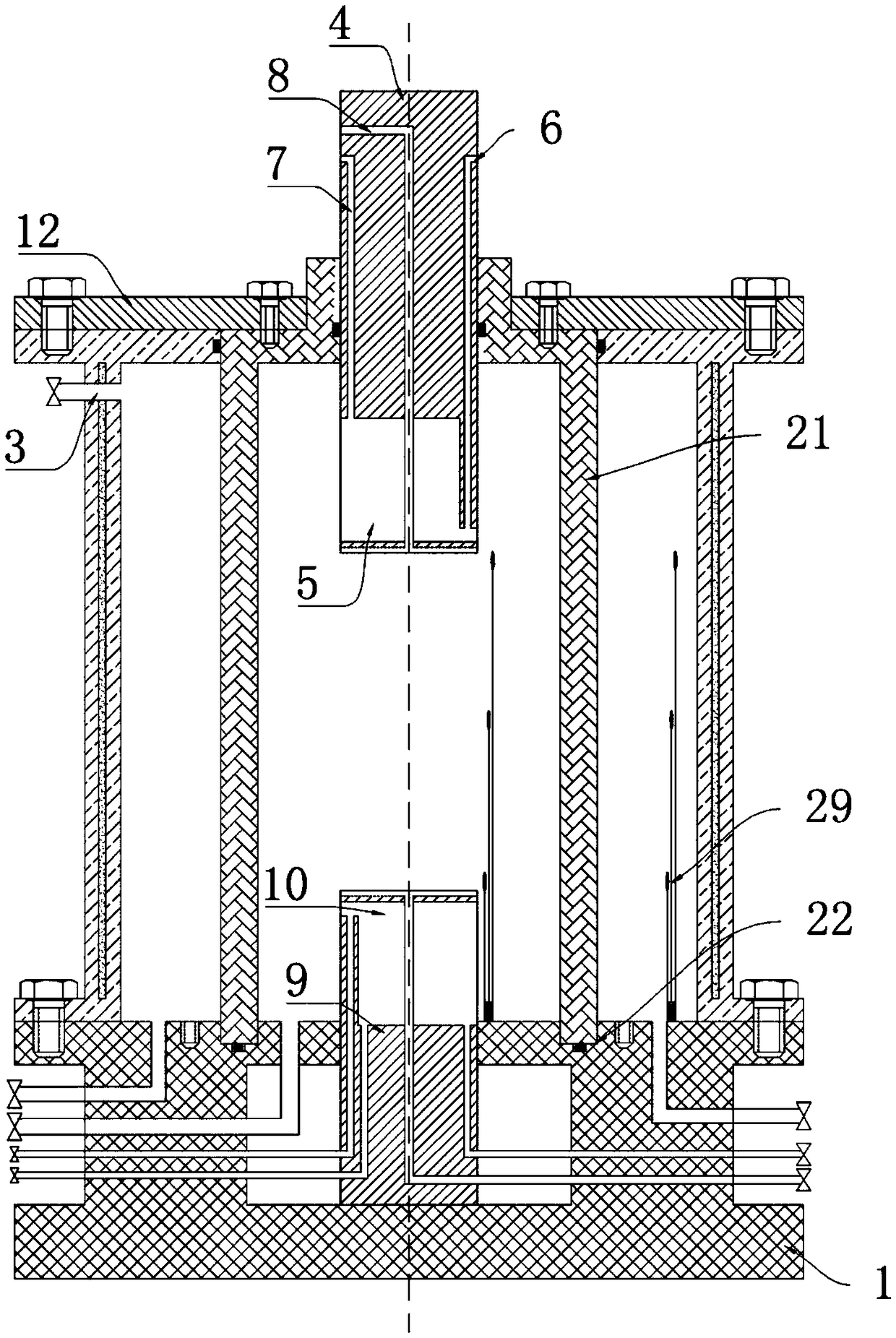

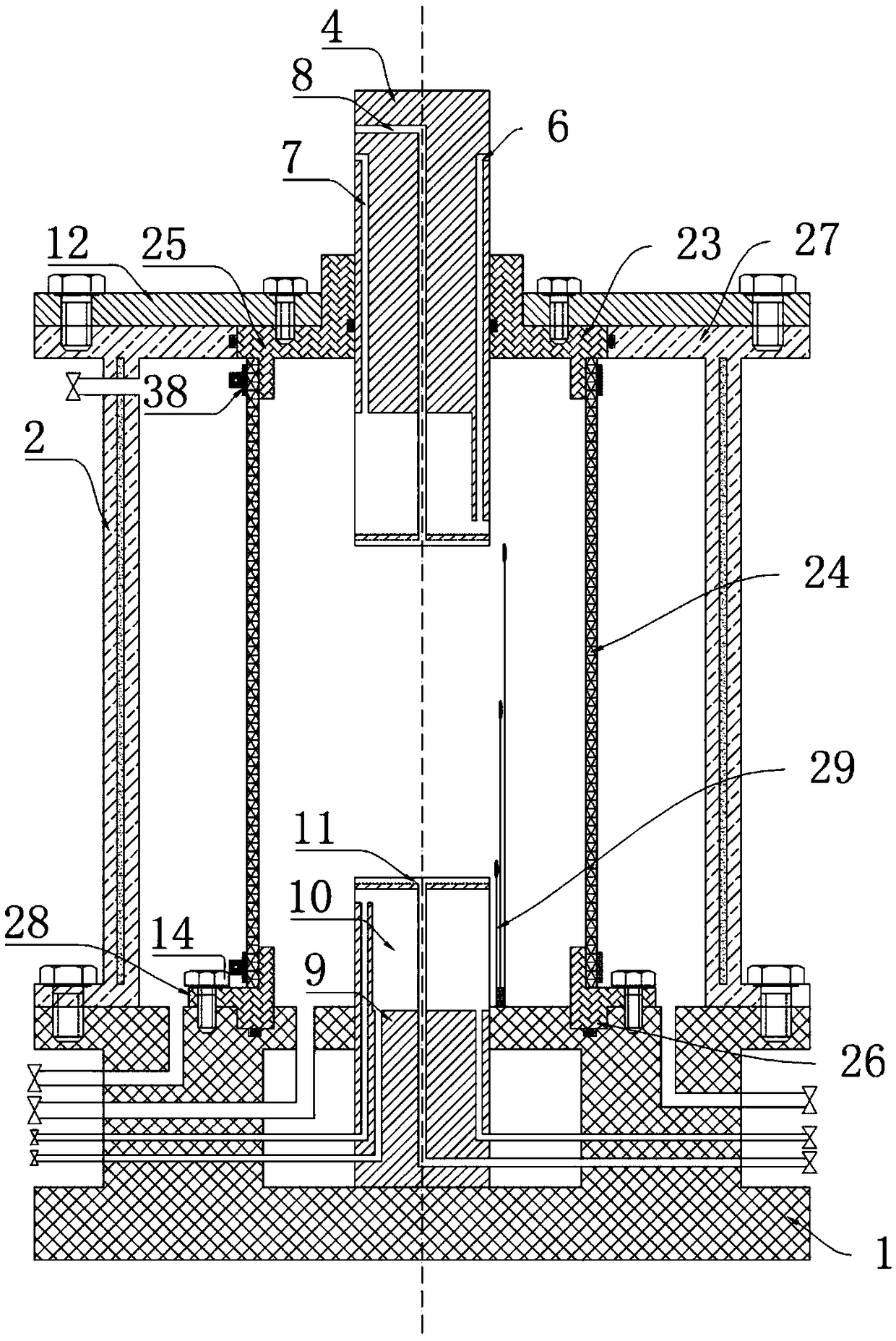

[0041] like Figure 1 to Figure 5 In the shown geotechnical material freeze-thaw thermal cycle triaxial seepage multifunctional pressure chamber, the cylindrical outer cavity 2 is fixed on the base 1 . The upper part of the side wall of the outer cavity body 2 is provided with an outer cavity circulating liquid outlet 3, and an inner cavity body is arranged in the outer cavity body 2, and the lower end of the inner cavity body is fixed to the base 1. The upper end of the inner cavity passes through the top cover 12 provided on the top of the outer cavity 2 , and an annular chamber is formed between the inner cavity and the outer cavity 2 . A heat insulation layer 39 is embedded in the side wall of the outer cavity 2 .

[0042] As a preferred mode of the present invention, the inner cavity has a two-stage tube 21 with a small top and a large bottom. In the ring gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com