An automatic drying system and method for live working equipment

A technology of live operation and drying system, applied in general control system, control/regulation system, program control and other directions, can solve problems such as major safety hazards, energy waste, insufficient drying time, etc., to ensure personal safety, prevent insulation fast aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

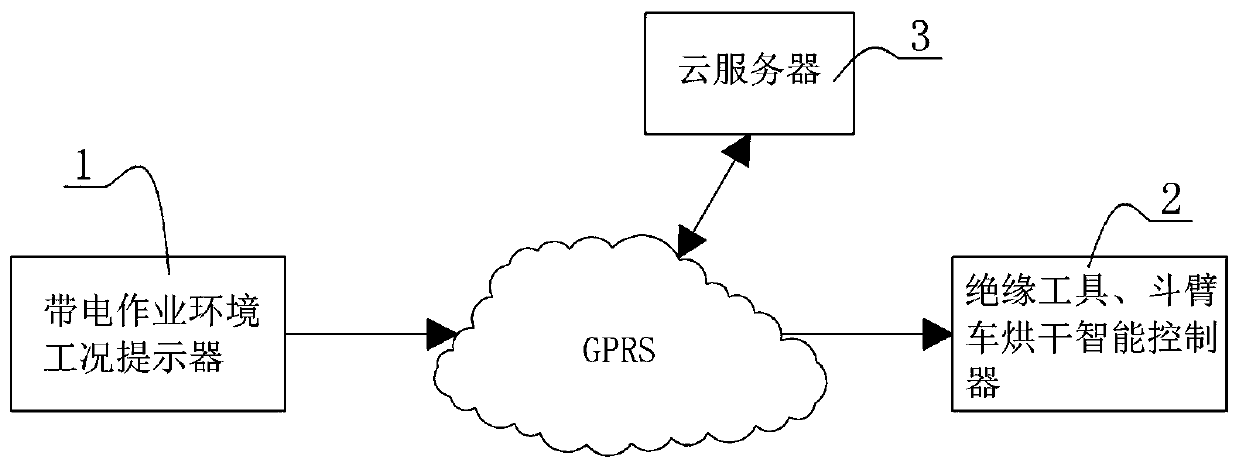

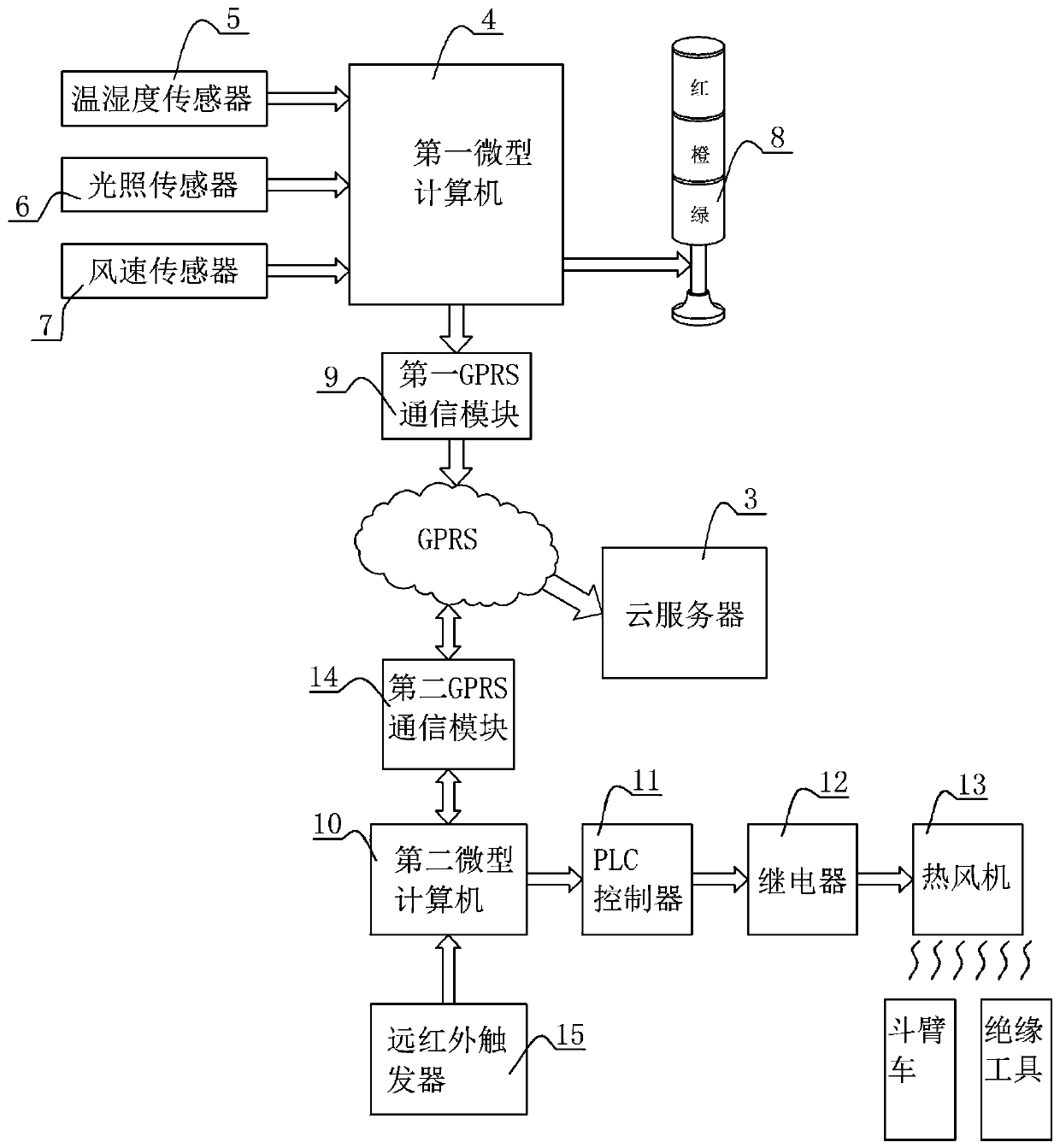

[0022] Such as figure 1 As shown, the principle diagram of the automatic drying system of the live working equipment of the present invention is given, which is composed of a live working environment working condition prompter 1 and an insulating tool and bucket arm truck drying intelligent controller 2. The live working working environment working condition The prompter 1 is fixed on the live working equipment and is used to detect the humidity, temperature, illuminance and wind speed in the working environment. The working condition prompter 1 of the live working environment transmits the collected humidity, temperature, illuminance and wind speed signals to the insulating tool and bucket arm truck drying intelligent controller 2 through the GPRS network, and also uploads them to the cloud server 3 at the same time. The intelligent controller 2 for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com