Gate drive circuit with forward and reverse scan function

A gate drive circuit, forward and reverse scanning technology, used in static indicators, instruments, etc., can solve the problems of asymmetric control signals, the circuit cannot operate normally, the pull-up control node netAn cannot be maintained, etc., to reduce space, Reduce the number and achieve the effect of narrow bezel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

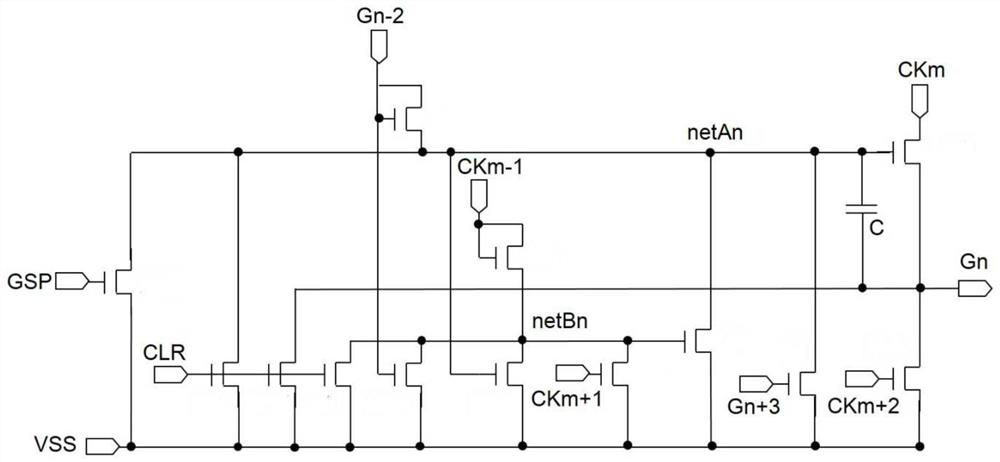

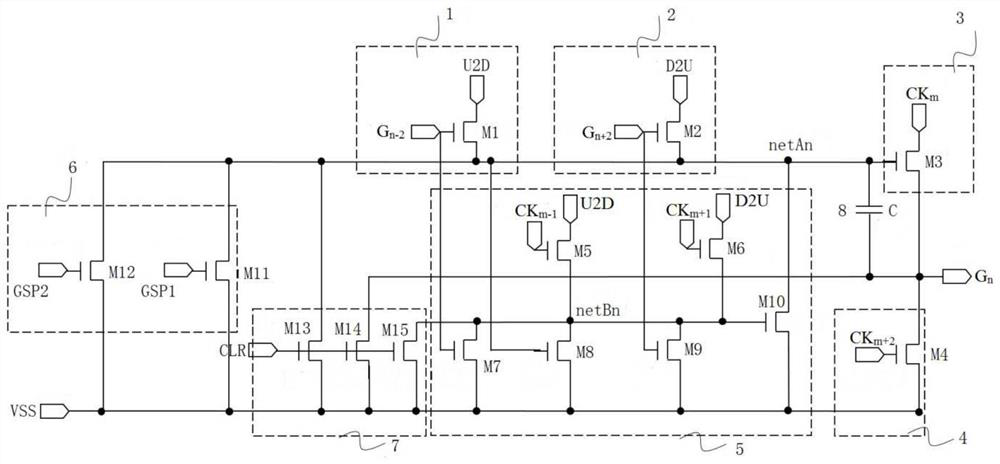

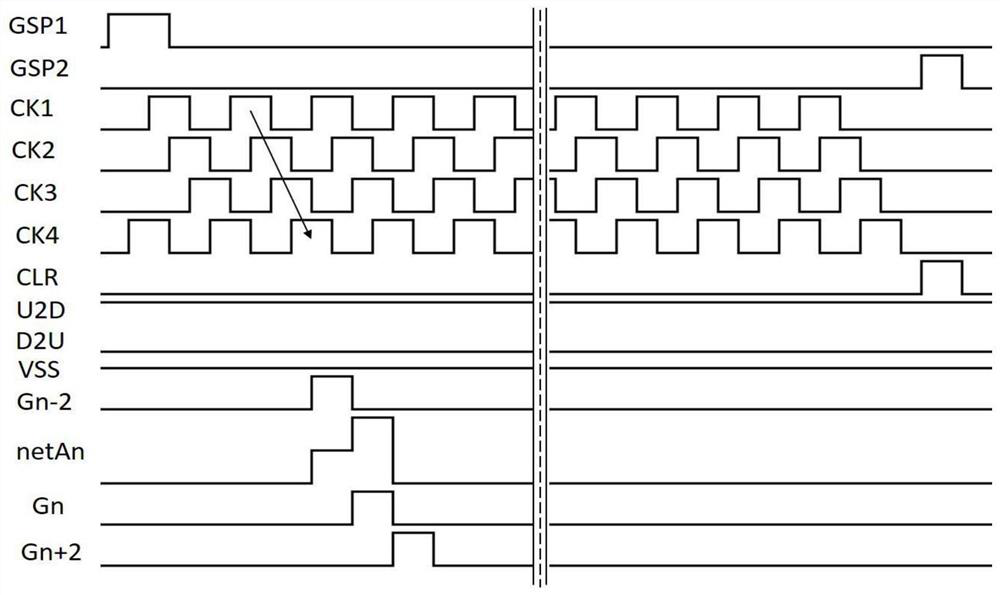

[0017] Such as figure 2 Shown is the circuit diagram of the gate drive circuit with forward and reverse scan functions according to the present invention, including forward scan pre-fill module 1, reverse scan pre-fill module 2, pull-up module 3, and gate scan signal maintenance Module 4, the maintenance module 5 of the pull-up control node, the auxiliary module 6, the empty reset module 7 and the bootstrap capacitor 8, the connection node of the forward scanning pre-charge module 1 and the pull-up module 3 is the pull-up control node netAn, and the upper The connection point of the pull module 3 and the maintenance module 4 of the gate scan signal outputs the gate scan signal G of the current stage n .

[0018] The specific circuit of the gate drive circuit is: forward scan pre-charge module 1, including a first thin film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com