Charging gun heat exchange structure and charging gun

A heat exchange structure and charging gun technology, applied in battery circuit devices, electrical equipment structural components, current collectors, etc., can solve problems such as large heat generation and hidden fire hazards of charging equipment, achieve low hidden dangers, avoid overheating and fire hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

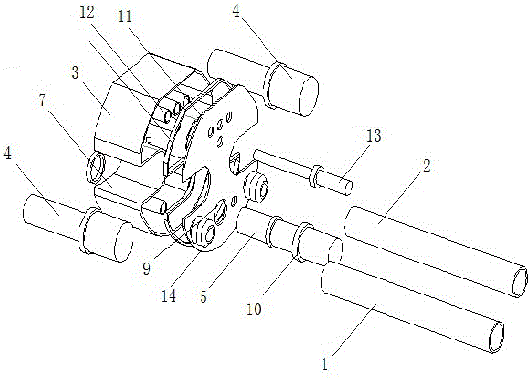

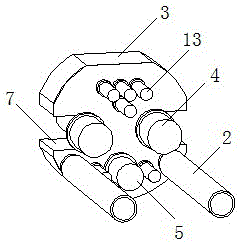

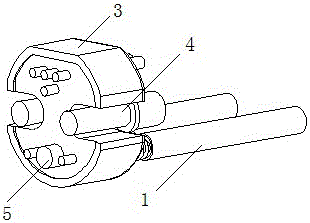

[0026] refer to Figure 1 to Figure 6 , in one embodiment, a charging gun heat exchange structure, including a heat exchange tank 3 arranged on the charging gun head 6, the heat exchange tank 3 is connected with the liquid inlet pipe 1 and the liquid outlet pipe 2, the main line terminal 4 and the ground wire terminal 5 pass through the heat exchange tank 3, and the cooling liquid flowing in from the liquid inlet pipe 1 flows through the heat exchange tank 3 and exchanges heat with the main wire terminal 4, and then flows from the liquid outlet pipe 2, the main line terminal 4 is electrically isolated from the cooling liquid in the heat exchange tank 3, and the ground wire terminal 5 is in electrical contact with the cooling liquid in the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com