Holing machine for limiting hole site

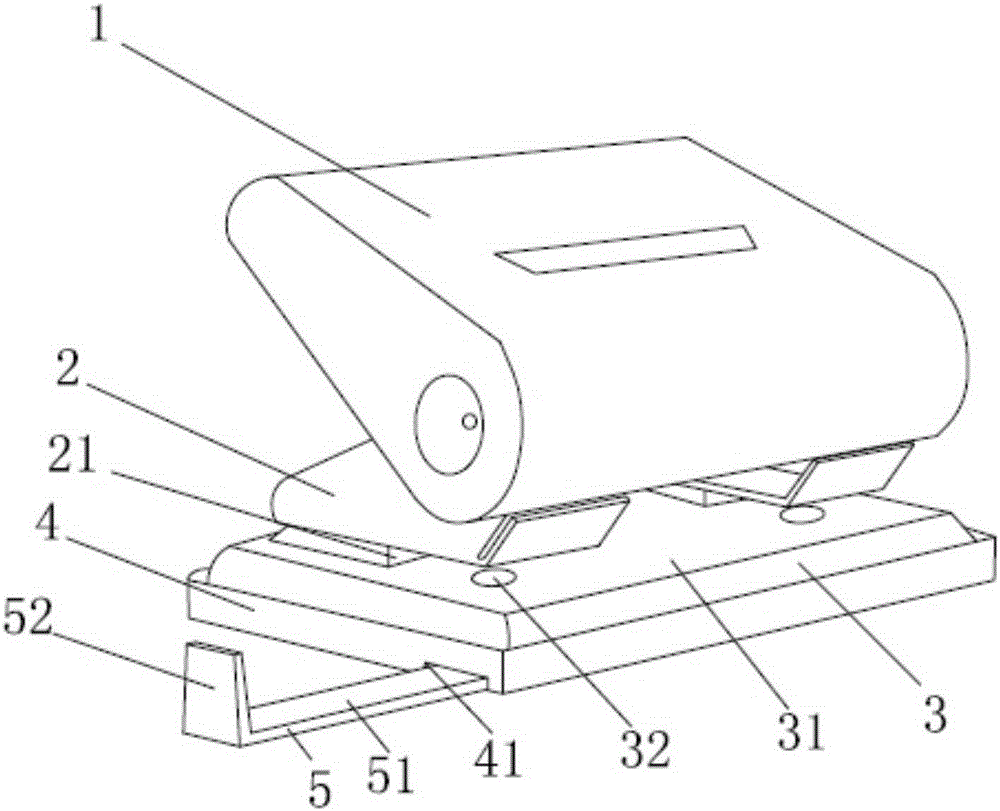

A technology for punching and limiting holes, which is applied in the field of punching machines, and can solve the problems of affecting the limiting sheet, unable to limit the fixing function of part 5, affecting the use of file managers, etc., and achieves the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

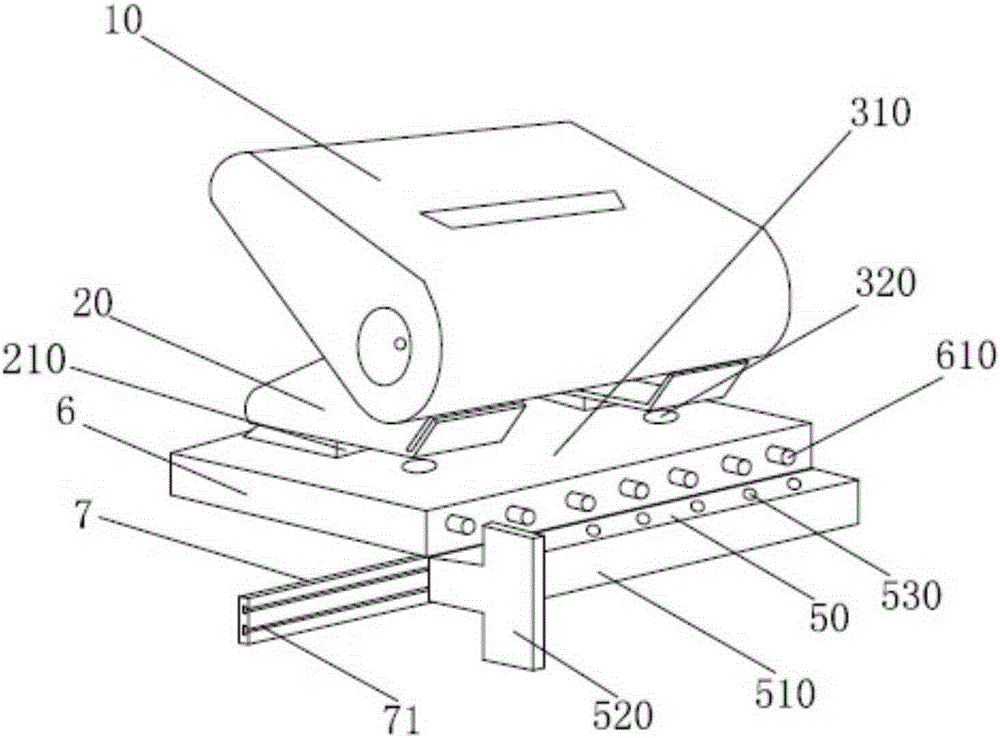

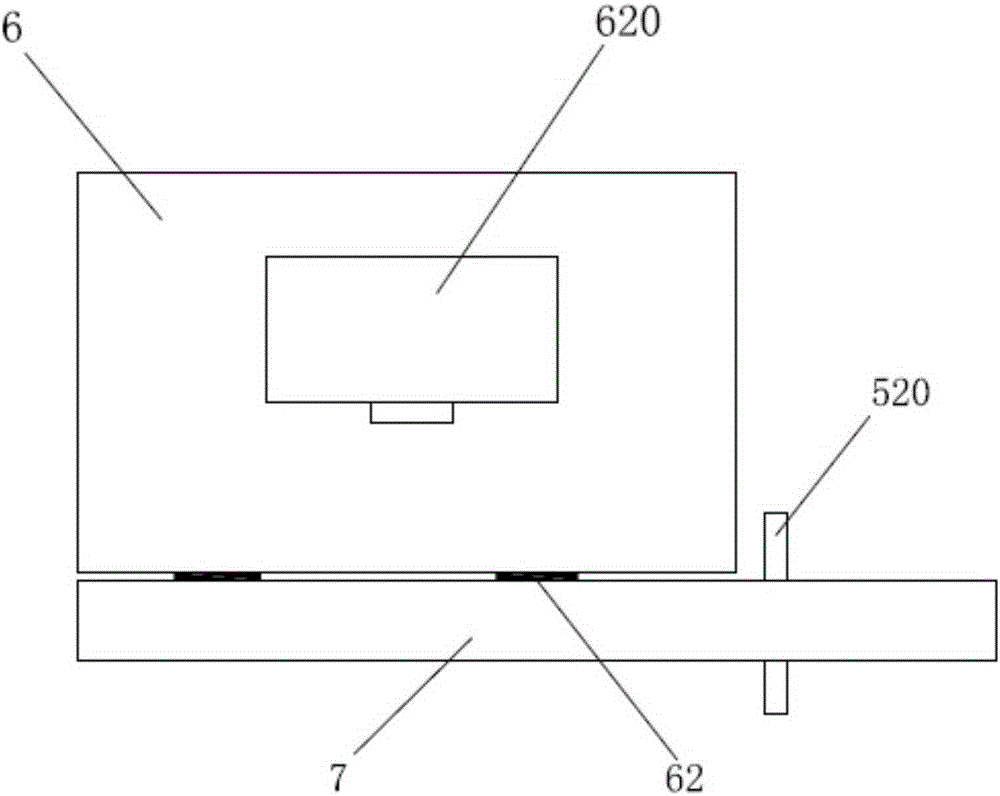

[0018] Such as figure 2 As shown, the supporting part 6 is a hollow structure, and the hollow structure allows the punching mechanism to pass through the through hole 320 to punch holes in the paper. A slide rail piece 7 is connected to the bottom edge of the front of the support portion 6 , and a slide groove 71 is provided on the surface of the slide rail piece 7 . The limiting part 50 is engaged with the sliding groove 71 and can slide along the slide rail piece 7. The end of the limiting part 50 is connected with a protruding limiting piece 520. The fronts of the support part 6 are spliced together, and the height of the limiting part 50 is equal to the height of the support part 6, which enables the paper to be placed evenly on the placement surface 310 of the support part 6, and prevents paper of the same specification caused by the height difference. The problem that the punching position is different depending on the paper.

[0019] A plurality of protruding limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com