High-aspect-ratio wing frame architecture design method

A design method and a technology with a large aspect ratio, applied in the field of aircraft, can solve the problems such as the inability to accurately measure the geometric aerodynamic twist angle distribution of the wing, the difficulty in obtaining the best lift-to-drag ratio, and the low cruising efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

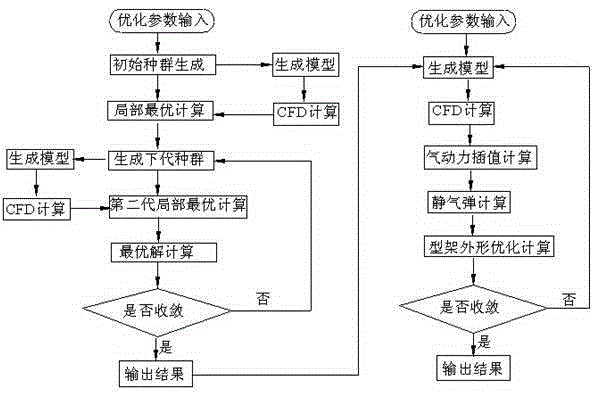

[0018] see figure 1 , a method for designing an airfoil structure with a large aspect ratio, comprising the following steps:

[0019] A. The rigid wing optimization step is to generate the initial population of the wing configuration, calculate the lift-to-drag ratio of the initial population, obtain the local optimal solution, perform optimization calculation on the obtained local optimal solution, and then obtain Calculate the lift-to-drag ratio of the local optimal solution and compare it with the local optimal solution obtained by calculating the lift-to-drag ratio of the initial population, select the global optimal solution, and finally judge the global optimal solution until convergence;

[0020] B. The elastic wing optimization step is to calculate the aerodynamic load on the elastic wing during flight, and then couple the structural static balance equation to calculate the elastic deformation of the wing. Through multiple iterative calculations, the elastic wing struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com