Intelligent garbage recycling equipment

A smart device and garbage technology, applied in garbage collection, garbage cans, household appliances, etc., can solve the problems of scattered garbage in the bucket, easy to generate odor, and low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

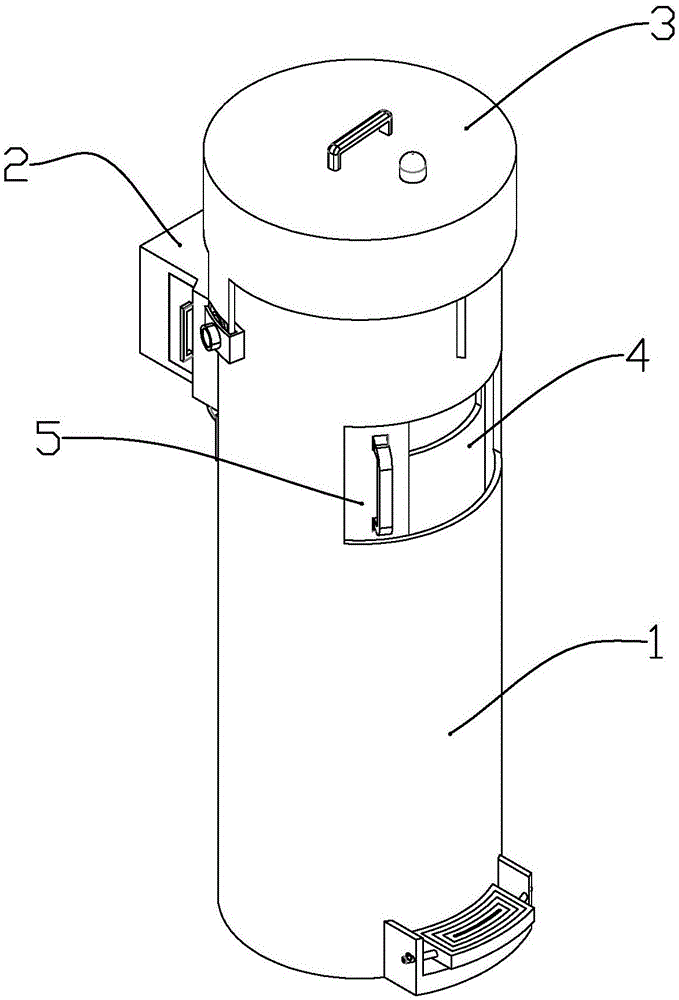

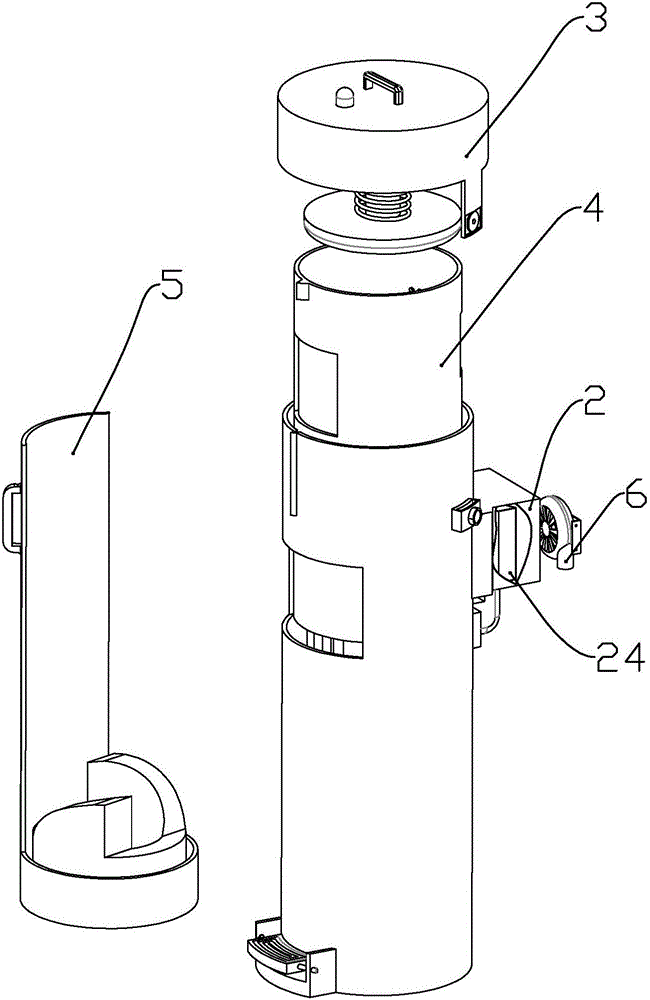

[0057] Such as Figure 1~Figure 11 , Figure 15 As shown, a garbage recycling smart device includes a barrel-shaped outer cylinder 1, an inner container 4 installed in the outer cylinder 1, and a handle compartment arranged between the outer cylinder 1 and the inner container 4. A cylinder 5, and a top cover 3 sleeved on the outer cylinder;

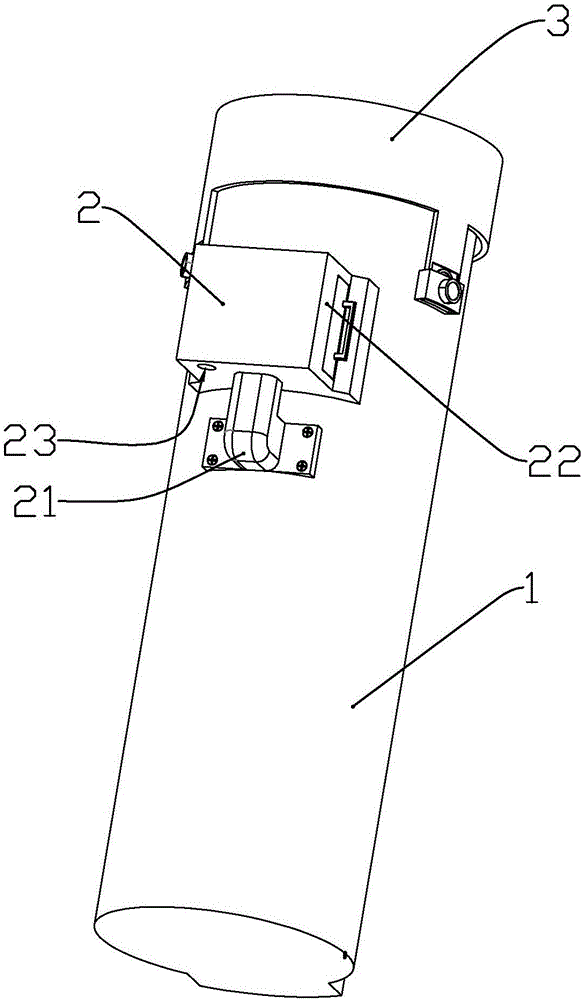

[0058] The outer cylinder 1 includes a cylinder body 11, and a V-shaped positioning slot 112 is formed on the inner wall of the upper end surface of the cylinder body along the axial direction of the cylinder body; the upper side wall of the cylinder body is located below the positioning slot and formed with a recovery Opening 111; the side wall of the cylinder body is formed with an exhaust outlet 116 at a position different from the recovery opening between the lower edge of the recovery opening and the upper edge of the cylinder; the upper side wall of the cylinder body is also symmetrically provided with a set of ear sockets 114 The...

Embodiment 2

[0095] Such as Figure 12 , Figure 13 , Figure 14 As shown, this embodiment has the following improvements on the basis of embodiment 1: an energy storage device 12 is installed at the outer lower part of the cylinder corresponding to the position of the recovery opening. The energy storage device includes a base 121 fixedly connected to the lower end of the barrel, a pedal 122 rotatably connected to the base through a rotating shaft 124, a connection joint 123 fixedly connected to the lower end of the pedal and connecting the pedal The connection mechanism 120 with the handle compartment; the connection mechanism includes a preloaded abutment plate 1202 fixedly connected to the inner wall of the cylinder body, a sliding push block 1205 for pushing the handle compartment to rotate, and one end fixedly connected The other end of the sliding push block is connected to the pre-tightening spring 1201 on the pre-tightening plate, and the pulley 1203 connected to the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com