Hydraulic jack base convenient to repair

A technology of hydraulic jack and seat body, applied in the field of hydraulic jack, can solve the problems of high cost, time-consuming and labor-intensive one-way valve, etc., and achieve the effect of convenient cleaning and avoiding inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

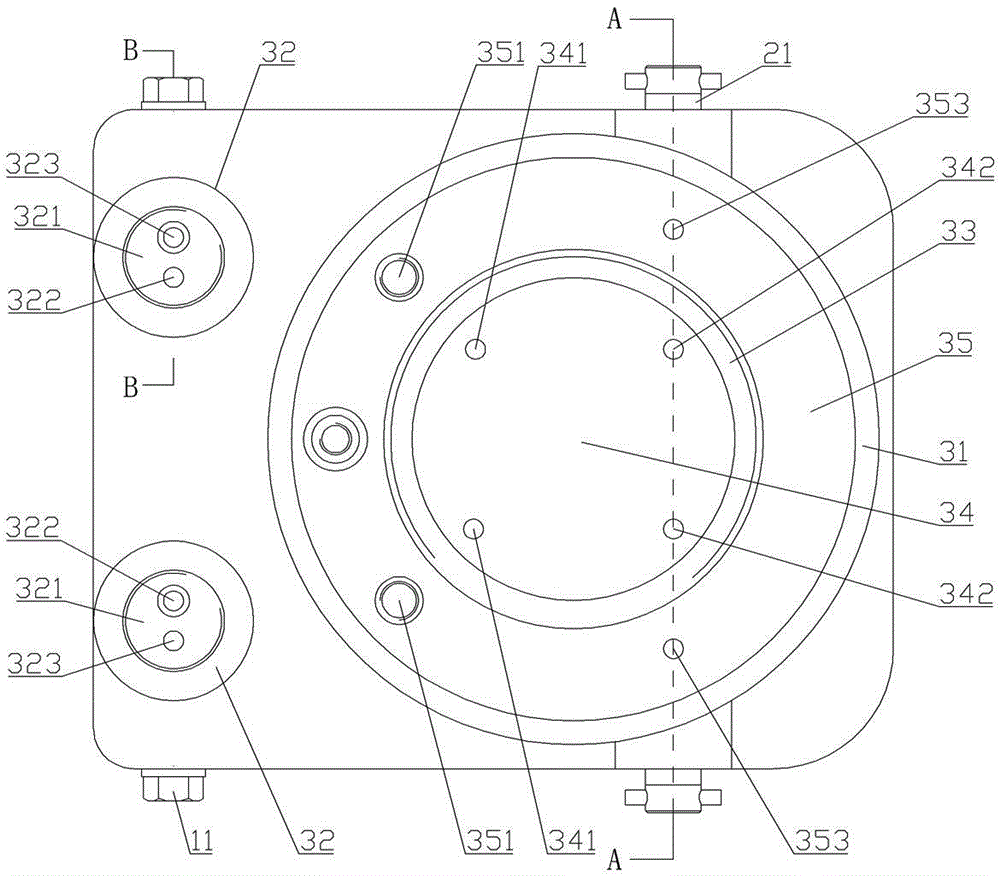

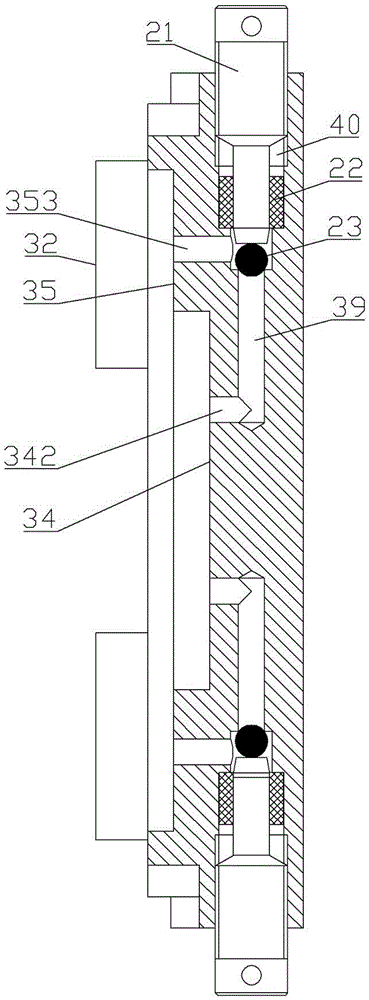

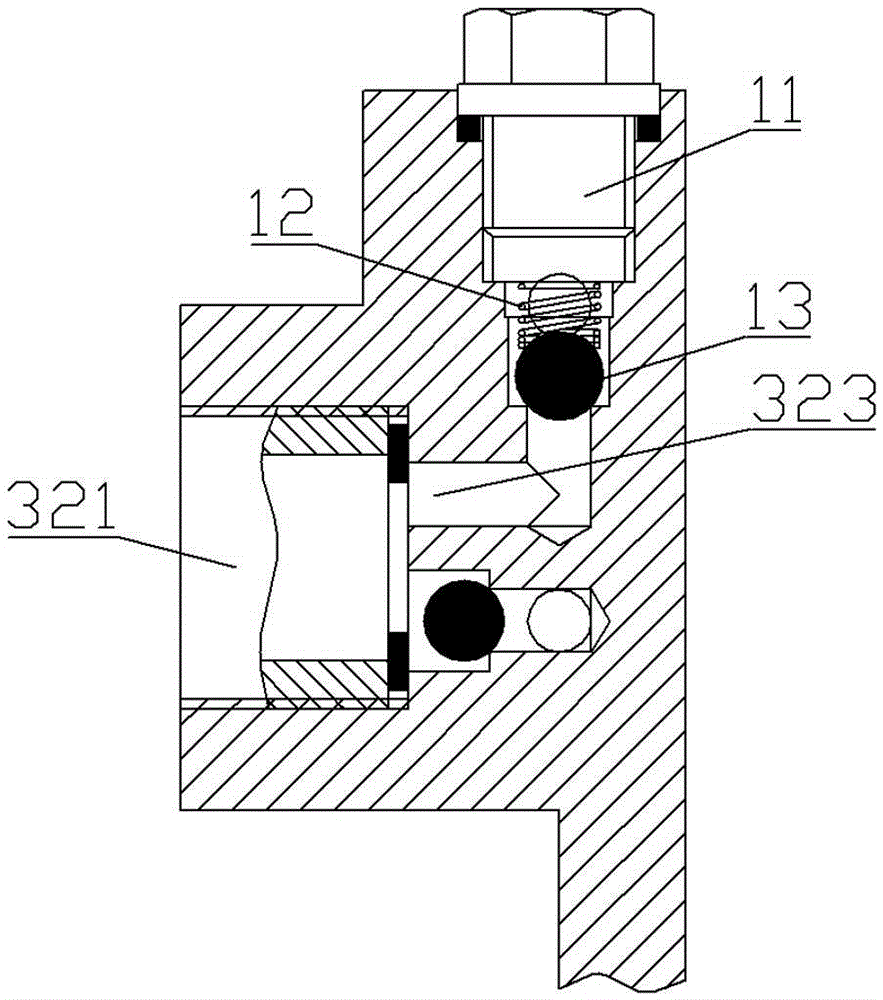

[0028] Such as Figure 1-7 As shown, the hydraulic jack base that is easy to maintain includes a one-way valve, an oil return valve and a seat body; the upper end surface of the seat body is provided with a housing installation groove 31, a boss 32 located outside the housing installation groove 31 and a housing installation groove 31 The oil cylinder installation groove 33 inside; the area inside the oil cylinder installation groove 33 is the bottom surface 34 of the working oil chamber, and the annular area between the shell installation groove 31 and the oil cylinder installation groove 33 is the bottom surface 35 of the oil storage chamber; the inside of the boss 32 is provided with a buffer chamber 321, the buffer chamber 321 is provided with a buffer chamber oil inlet 322 and a buffer chamber oil drain port 323; the oil storage chamber bottom surface 35 is provided with an oil storage chamber oil drain port 351 and an oil storage chamber oil inlet 353, and the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com