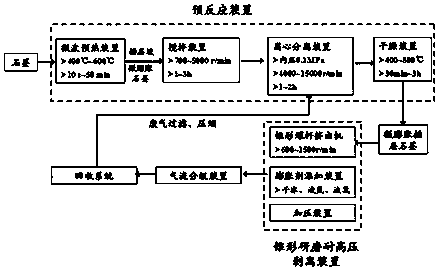

A complete set of equipment for dry conical grinding and exfoliating graphene

A stripping device and cone-shaped technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of difficult removal of solvent residues, product pollution, etc., to improve the efficiency of mechanical stripping, reduce exhaust emissions, and improve the utilization rate of raw materials and products. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0021] Take by weighing 150g1-ethyl-3-methylimidazole trifluoromethanesulfonimide, and be dissolved in 850g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant, cool for subsequent use;

[0022] will step Cool and dry graphite in the middle, add it after metering through the feed port of the pre-reaction device, heat it to 450±5°C through the microwave preheating device, and control the microwave preheating time at 30 min, so that the graphite raw material can form micro-expanded graphite, and then mix with After metering the layer liquid feed port, add 800ml of intercalation solution, and transfer the mixture to the stirring device for pre-intercalation reaction. The stirring device rotates at 3500 rp...

Embodiment 2

[0027] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0028] Take by weighing 150g1-ethyl-3-methylimidazole trifluoromethanesulfonic acid, and be dissolved in the 850g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant, cool for subsequent use;

[0029] will step The graphite that is cooled and dried in the middle is added after metering through the feed port of the pre-reaction device, heated to 450±5°C by the micro-bo pre-heating device, and the microwave pre-heating time is controlled at 30 min, so that the graphite raw material forms micro-expanded graphite, and then passed through After metering the intercalation liquid inlet, add 900ml of intercalation liquid, and transfer the mixture to the stirring device for pre-intercalation reaction. The stirr...

Embodiment 3

[0034] Weigh 500g of commercially available graphite and place it in a constant temperature box-type drying oven at 80°C for 2 hours to remove moisture and other impurities adsorbed on the graphite surface, and cool it for later use;

[0035] Take by weighing 200g1-ethyl-3-methylimidazole trifluoromethanesulfonyl carbon, and be dissolved in 900g propylene carbonate solvent, prepare the propylene carbonate solution with surfactant, cool for subsequent use;

[0036] will step The graphite that is cooled and dried in the middle is added after metering through the feed port of the pre-reaction device, and heated to 500±5°C by the micro-wave pre-heating device, and the microwave pre-heating time is controlled at 35 min, so that the graphite raw material forms micro-expanded graphite, and then is mixed with the After metering the intercalation liquid inlet, add 900ml of intercalation liquid, and transfer the mixture to the stirring device for pre-intercalation reaction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com