A kind of preparation method of expanded graphite

A technology of expanded graphite and flake graphite, which is applied in the direction of graphite, etc., can solve the problems of difficult continuous production of graphite and long production cycle of expanded graphite, and achieve the effect of complete oxidation of graphite, short production cycle and continuous reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

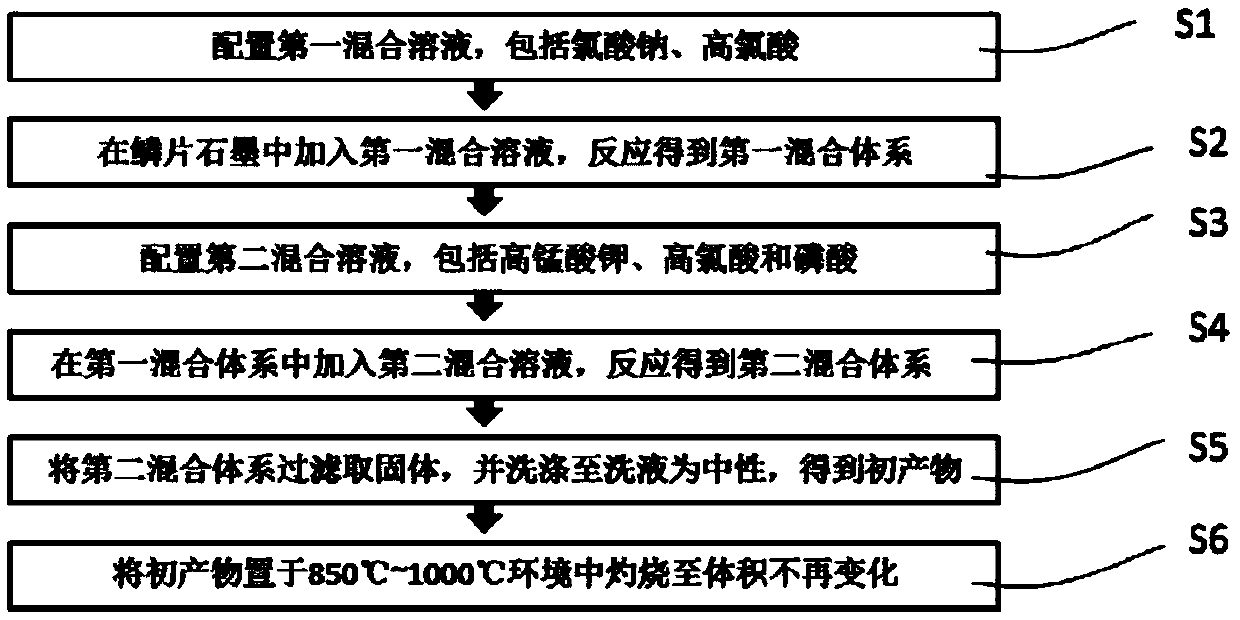

[0037] A kind of preparation method of expanded graphite of the present invention, such as figure 1 shown, including the following steps:

[0038] S1. Prepare a first mixed solution, including sodium chlorate and perchloric acid, and the ratio of the sodium chlorate to the perchloric acid is 0.1 g: 6 mL.

[0039] S2. Add the first mixed solution to the flake graphite, stir at 30°C at 100r / min for 3min, and then stir at 300r / min for 20min to obtain the first mixed system; the particle size of the flake graphite is 30 mesh, and the flake graphite The ratio with the first mixed solution is 3g:4mL.

[0040] The first mixing system was subjected to ultrasonic vibration for the first time for 8 minutes, and the ultrasonic power was 600w.

[0041] S3. Configure a second mixed solution, including potassium permanganate, perchloric acid and phosphoric acid; the ratio of potassium permanganate, perchloric acid and phosphoric acid in the second mixed solution is 1g: 3mL : 1mL.

[0042]...

Embodiment 2

[0049] A kind of preparation method of expanded graphite of the present invention, comprises the steps:

[0050] S1. Prepare a first mixed solution, including sodium chlorate and perchloric acid, the ratio of the sodium chlorate to the perchloric acid is 2g:4mL.

[0051] S2. Add the first mixed solution into the flake graphite, stir at 20°C at 80r / min for 5min, and then stir at 280r / min for 30min to obtain the first mixed system; the particle size of the flake graphite is 20 mesh, and the flake graphite The ratio with the first mixed solution is 2g:1mL.

[0052] The first mixing system was subjected to ultrasonic vibration for the first time for 5 minutes, and the ultrasonic power was 800w.

[0053] S3. Configure a second mixed solution, including potassium permanganate, perchloric acid and phosphoric acid; the ratio of potassium permanganate, perchloric acid and phosphoric acid in the second mixed solution is 2g: 6mL : 0.1mL.

[0054] S4. Add the second mixed solution into...

Embodiment 3

[0060] A kind of preparation method of expanded graphite of the present invention, comprises the steps:

[0061] S1. Prepare a first mixed solution, including sodium chlorate and perchloric acid, and the ratio of the sodium chlorate to the perchloric acid is 1 g: 1 mL.

[0062] S2. Add the first mixed solution to the flake graphite, stir at 45°C at 120r / min for 1min, and then stir at 350r / min for 10min to obtain the first mixed system; the particle size of the flake graphite is 35 mesh, and the flake graphite The ratio with the first mixed solution is 2g:3mL.

[0063] The first mixing system was subjected to ultrasonic vibration for the first time for 10 minutes, and the ultrasonic power was 500w.

[0064] S3, configure the second mixed solution, including potassium permanganate, perchloric acid and phosphoric acid; the ratio of the potassium permanganate, the perchloric acid and the phosphoric acid in the second mixed solution is 0.1g: 1mL: 2mL.

[0065] S4. Add the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com