Environment-friendly type composite disperse dye and preparation method and application thereof

A compound dispersion and environmental protection technology, applied in dyeing method, organic dyes, textiles and paper making, etc., can solve the problems of poor compatibility, poor dyeing head and tail, overflow dyeing prone to color flowers, etc., to achieve good compatibility, Good hiding property and excellent light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

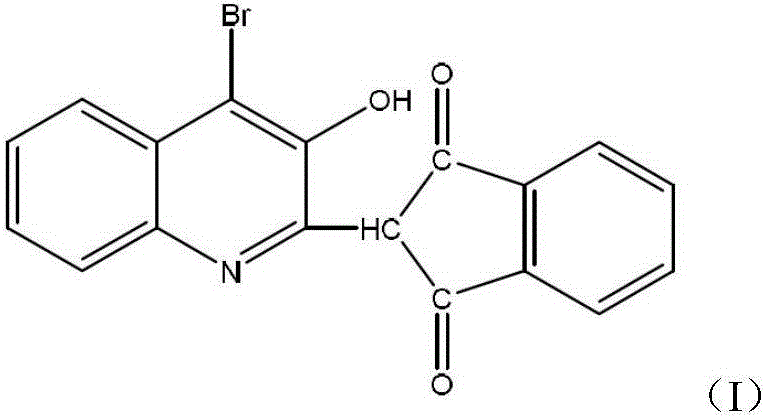

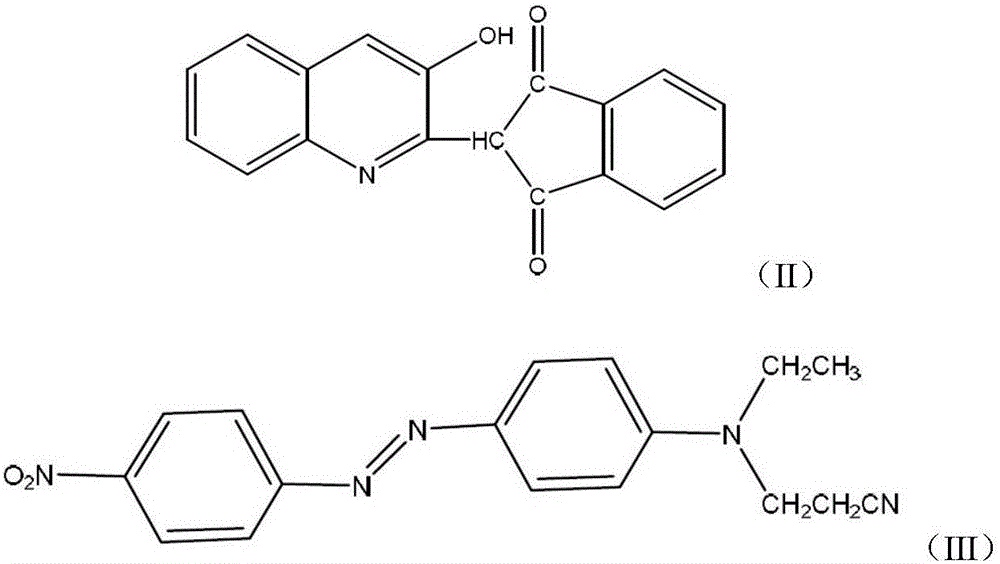

Method used

Image

Examples

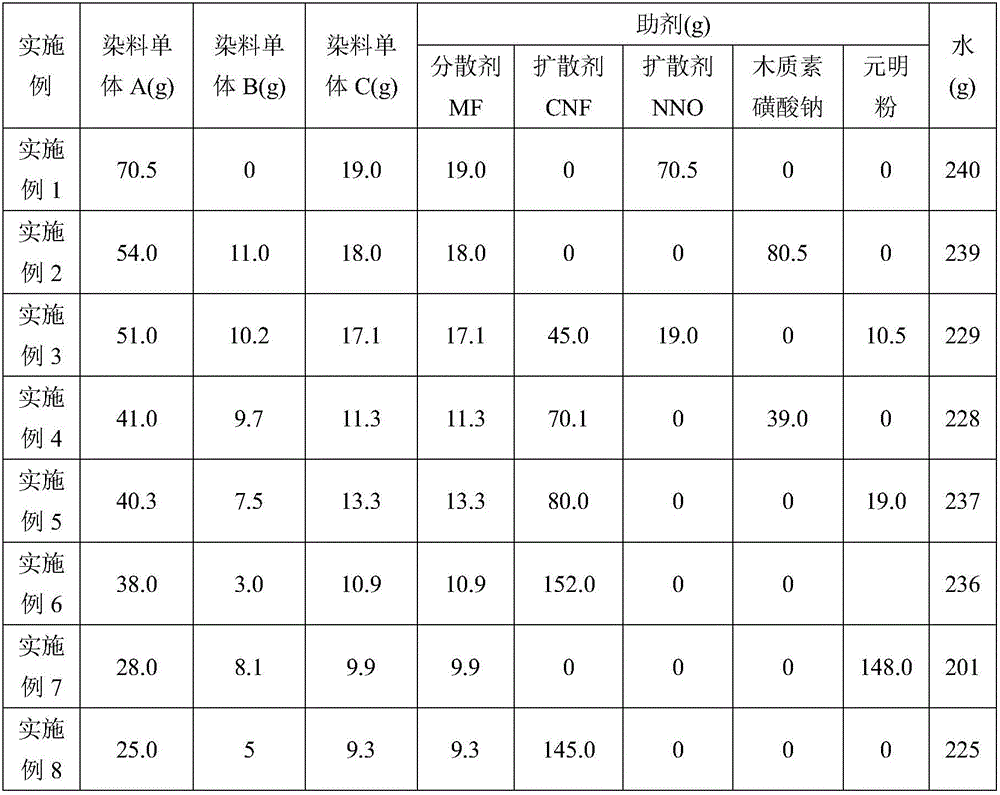

Embodiment 1~8

[0048] According to the metering data shown in Table 1, dye monomer A, dye monomer B, auxiliary agent [dispersant MF (methylnaphthalene sulfonate formaldehyde condensate), diffusing agent CNF (benzyl naphthalene sulfonate formaldehyde condensate) , diffusing agent NNO (naphthalene sulfonic acid formaldehyde condensate), sodium lignin sulfonate, Yuanming powder] After adding water and blending, use SB250 sand mill according to the flow rate of 0.5 ~ 1.0m 3 Grind and disperse at 120-135°C, spray pressure 3.5-5.0MPa, solid content 40%-45% and spray dry.

[0049] Table 1

[0050]

Embodiment 9~11

[0052] According to the measurement data shown in Table 2, C.I. Disperse Yellow 64, C.I. Disperse Yellow 54, C.I. Disperse Orange 25, auxiliary agent [dispersant MF (methylnaphthalenesulfonic acid formaldehyde condensate), diffusing agent CNF (benzylnaphthalenesulfonic acid Salt formaldehyde condensate), diffusing agent NNO (naphthalene sulfonate formaldehyde condensate), sodium lignin sulfonate, Yuanming powder] After adding water and blending, use SB250 grinder to grind and disperse according to the flow rate of 0.5~1.0m3 / h, Spray drying under the conditions of 120-135°C, spray pressure 3.5-5.0MPa, and solid content 40%-45%.

[0053] Table 2

[0054]

[0055]

Embodiment 12~15

[0057] According to the data shown in Table 3, C.I. Disperse Yellow 64, C.I. Disperse Yellow 54, C.I. Disperse Orange 25, additives [dispersant MF (methylnaphthalenesulfonic acid formaldehyde condensate), diffusing agent NNO (naphthalenesulfonic acid formaldehyde condensate) , Sodium Lignosulfonate, Sodium Sodium Sulfonate] Blend directly and grind until evenly dispersed.

[0058] table 3

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com