Low-temperature environment-friendly dispersed dye

An environmentally friendly disperse dye technology, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of color incompatibility, dark color, incompetence, etc., and achieve ideal compatibility and compatibility, bright color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

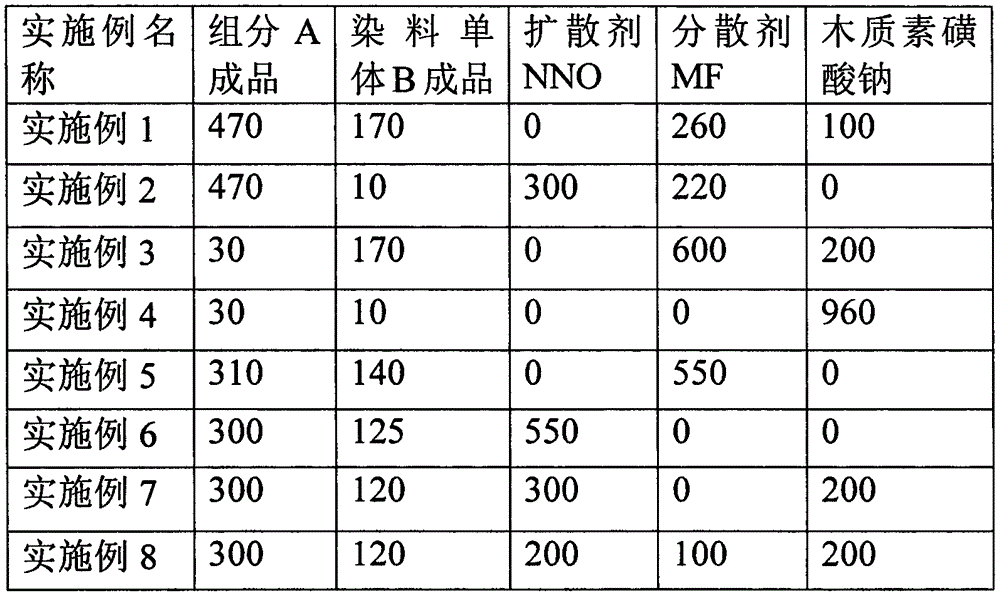

[0026] Embodiment 1-8: According to the data shown in Table 1, the component A finished product (component A content 53%), dyestuff disperse orange E-RL250% (monomer B content 42%), auxiliary agent are fully mixed in a stirring pot Stir well, then commercialize.

[0027] Table 1 Unit weight: grams

[0028]

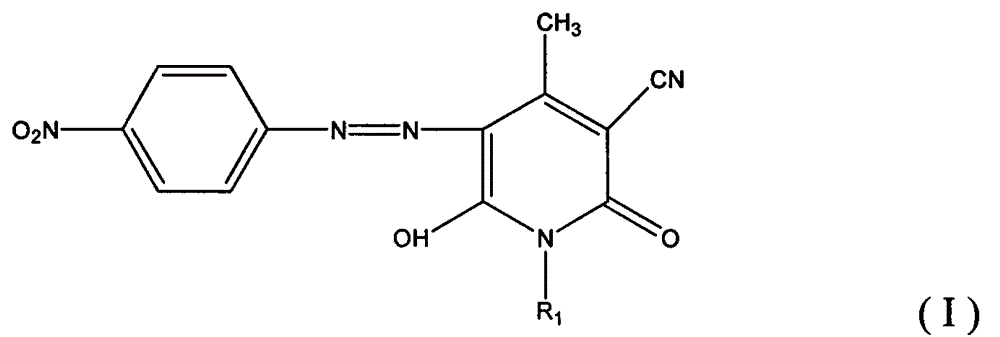

[0029] In embodiment 1-8, the substituent R corresponding to one or more dye monomers shown in formula (I) constituting component A 1 , and the weight of the dye monomer corresponding to each substituent is listed in Table 2:

[0030] Table 2

[0031]

[0032] Examples 9-16: According to the data shown in Table 3, component A, dye monomer B, additives, water or other wetting agents were mixed, ground and dispersed with a grinder, spray-dried, and then commercialized.

[0033] Table 3 Unit weight: grams

[0034]

[0035] In embodiment 9-16, the corresponding substituent R of one or more dye monomers shown in formula (I) constituting component A 1 , and the wei...

Embodiment 17

[0038] Embodiment 17: respectively get the disperse dye that 0.5 gram embodiment 1-18 makes and disperse in the water of 500ml, draw 20ml in the dyeing cup, add the distilled water of 80ml, with 10% (weight fraction) acetic acid will dye in the cup Adjust the pH value of the dye solution to 4.5-5.0, add 2.0 grams of polyester fiber cloth at room temperature, tighten the cup cover, and weigh 0.5 grams of Disperse Yellow E-GL produced by Longsheng Company, disperse it in 500ml of water, and absorb 20ml is the same as in the dyeing cup, add 80ml of distilled water, adjust the pH value of the dyeing solution in the dyeing cup to 4.5-5.0 with 10% (weight fraction) acetic acid, add 2.0 grams of polyester fiber cloth at room temperature, and tighten the cup cover , put the two staining cups into the dyeing machine at the same time, raise the temperature from room temperature to 130°C, and keep it warm for 30 minutes. Cool to about 60°C, open the cup lid, take out 2.0 grams of polyest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com