Weaving technology for three-dimensional embossment weft knitting fabric

A three-dimensional embossing and weft knitting technology, applied in the field of weft knitted fabrics, can solve the problems of low production efficiency and complex three-dimensional pattern weaving process, and achieve the effect of well-arranged structure, excellent performance, and thick and warm texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments.

[0018] In this embodiment, a weaving process of a three-dimensional embossed weft-knitted fabric is weaved by a weft-knitted double-sided jacquard machine, and computerized jacquard is used, which is divided into two areas:

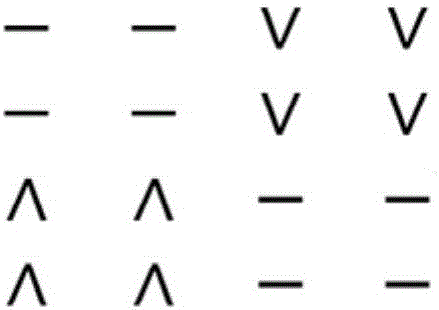

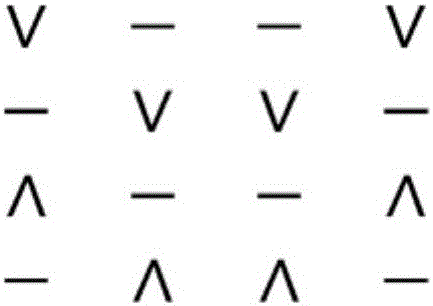

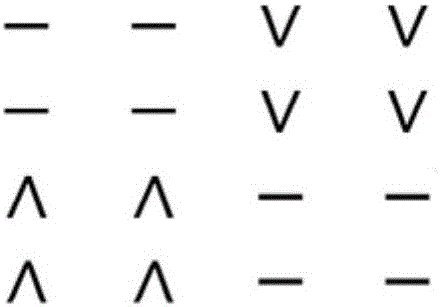

[0019] Among them, the stitches in the pattern area are organized as follows:

[0020]

[0021] The first road and the second road are combined into one road, using coarse sand for high-density weaving on the surface of the fabric, and the third road and the fourth road are combined into one road, using fine sand mixed with a spandex covered yarn to carry out low-density weaving on the back of the fabric. Density weaving; the coarse sand used in the first and second roads is three strands of 200D / 72F nylon heavy mesh DTY. The fine sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com