A method for pulling out prestressed pipe piles of a bridge abutment and its supporting equipment

A technology of prestressed pipe piles and supporting equipment, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of long construction period, large hole expansion rate of bored piles, and noise impact, and achieve the construction hole expansion rate Small size, improved pile pulling efficiency, and low noise impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

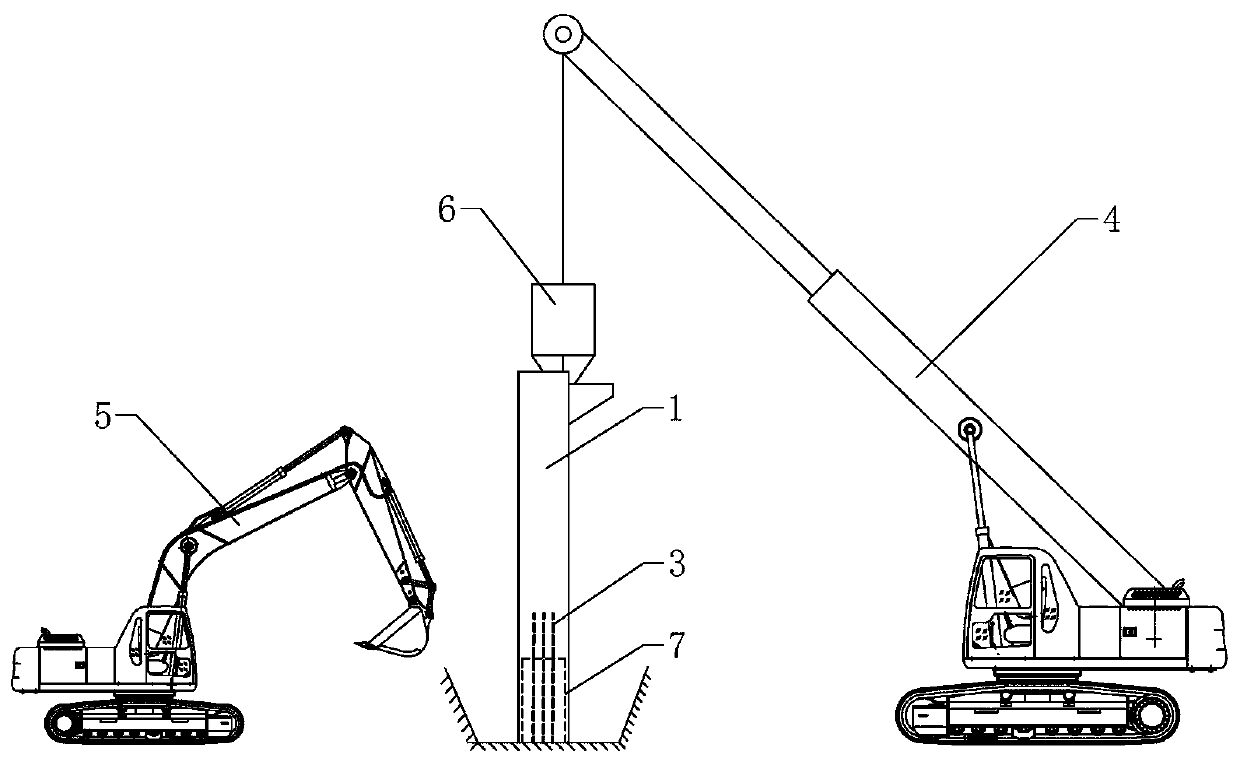

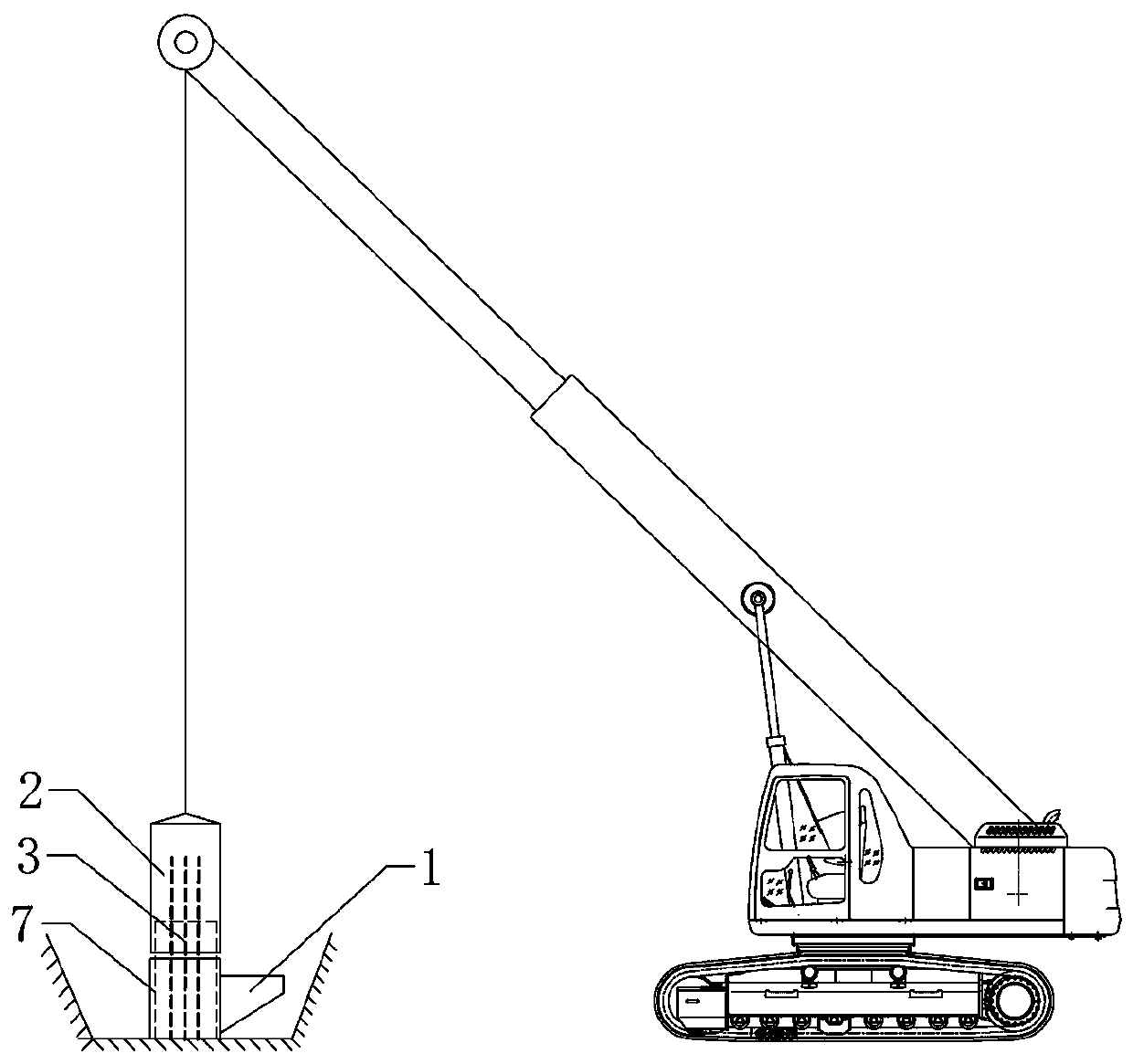

[0035] The length of the prestressed pipe pile 7 to be pulled is 22 meters. The supporting equipment for the method of pulling out the prestressed pipe pile of the abutment includes 4 cranes, 6 vibrating hammers, 5 excavators, 1 sinking steel pipe, and chuck plates 2 and tensile steel bar 3, the diameter of tensile steel bar 3 is ∅25, and the length is 22 meters.

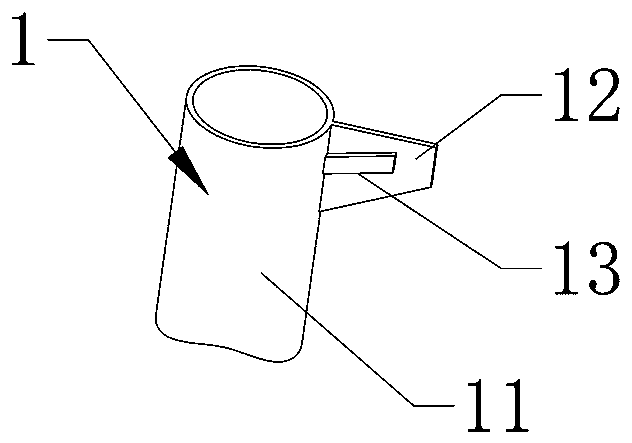

[0036] according to image 3 , Figure 4 As shown, the sinking steel pipe 1 includes a hollow cylindrical pipe body 11 and an overhanging vibration plate 12 at the head of the pipe body 11, and the overhanging vibration plate 12 and the head of the pipe body 11 are welded into a unified whole . Reinforcing ribs 13 are welded on both sides of the overhanging vibration plate 12, the overhanging vibration plate 12 is made of 20mm thick steel plate, and the sinking steel pipe 1 is 25 meters in length.

[0037] The chuck plate 2 includes a splint 21 and a hanging plate 22, the upper end of the hanging plate 22 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com