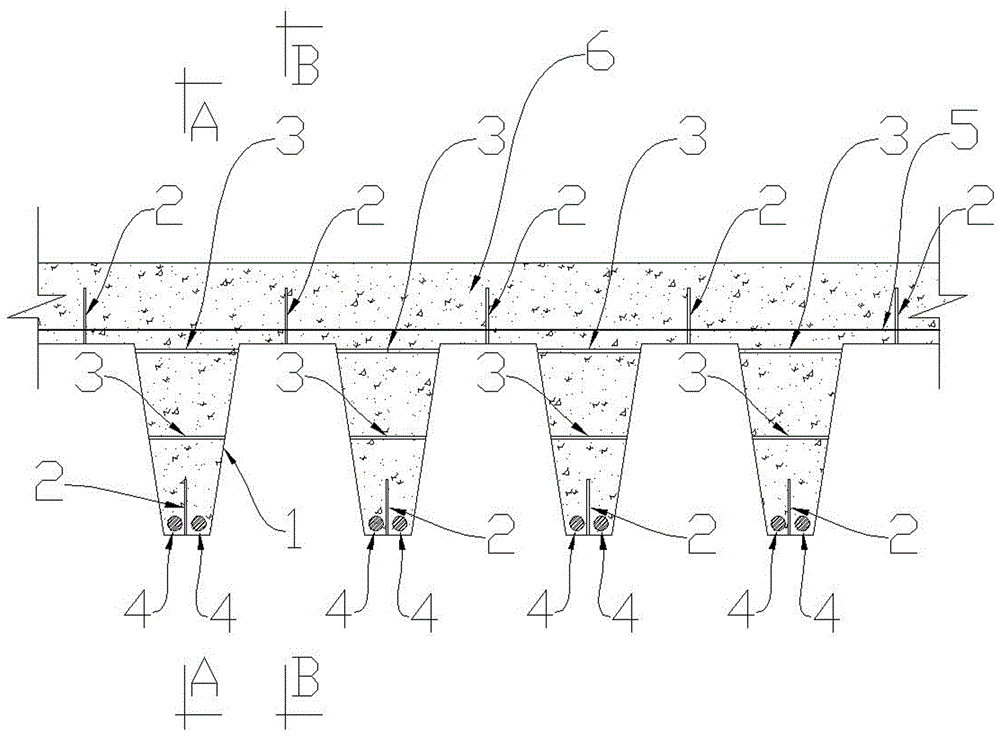

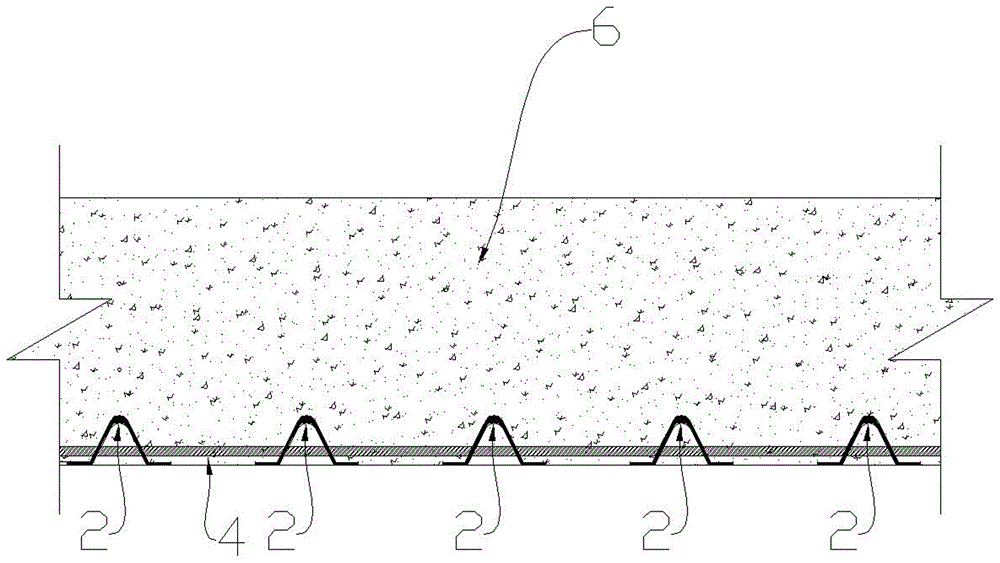

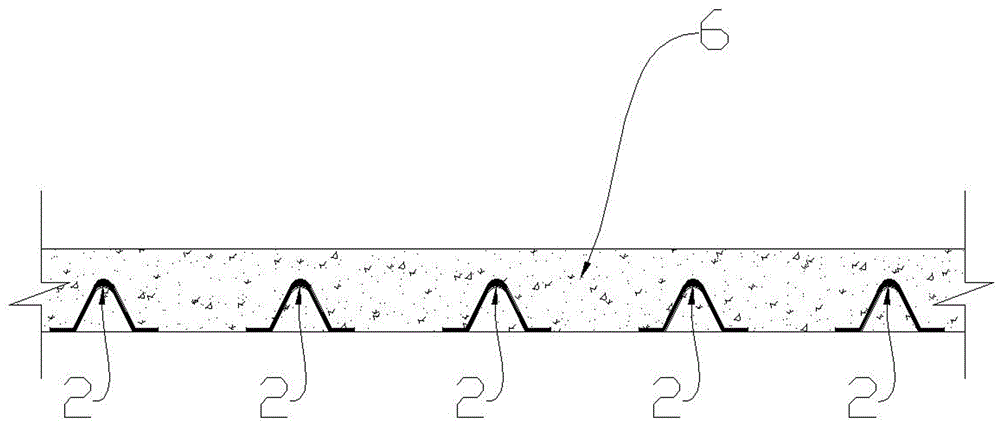

Composite floor jointly stressed by corrugated steel and cast-in-place reinforced concrete

A technology of reinforced concrete and corrugated steel plates, applied to floors, building components, buildings, etc., can solve problems such as time-consuming, laborious and cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] First, the single corrugated steel plate 1, the anchoring steel bar 2 and the tie bar 3 are processed and welded in the factory, and then multiple single corrugated steel plates 1 are installed on the construction site and the longitudinal joint is installed at the longitudinal joint of the two corrugated steel plates 1 Plate 12 and ensure that the cast-in-place concrete at the joint will not leak grout, place the longitudinal stress main reinforcement 4 in the groove at the bottom of the corrugated steel plate 1, place the transverse stress reinforcement 5 at the upper end of the corrugated steel plate 1, and finally pour the cast-in-place concrete 6 , the entire construction process is completed; it needs to be explained: when the floor slab is subjected to external loads, the anchoring steel bars 2 can prevent slippage and separation between the corrugated steel plate 1 and the cast-in-place concrete 6, and can ensure that the corrugated steel plate 1 and the cast-in-p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap