A component connection structure and a display base connection device

A connection structure and component technology, which is applied in the field of component connection structure and display base connection device, can solve the problems of inevitable gaps, poor connection stability, and inability to connect two components together, and achieves great practical significance in production, Easy to assemble and disassemble, good for production applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

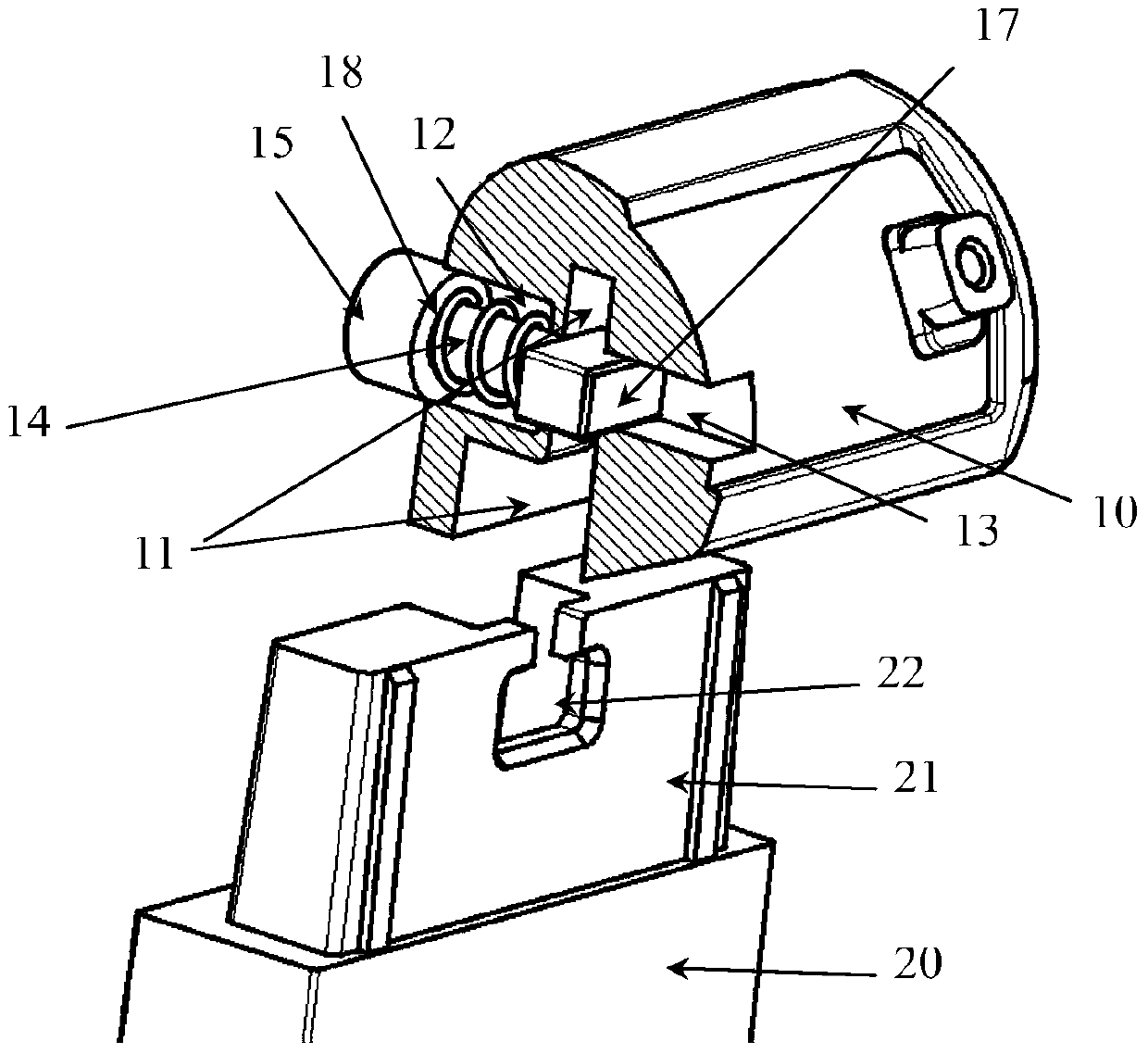

[0035] see figure 1 , the present invention provides a component connection structure, including a first connection piece 10 and a second connection piece 20, and the first connection piece 10 and the second connection piece 20 are installed on the shells of the two components respectively.

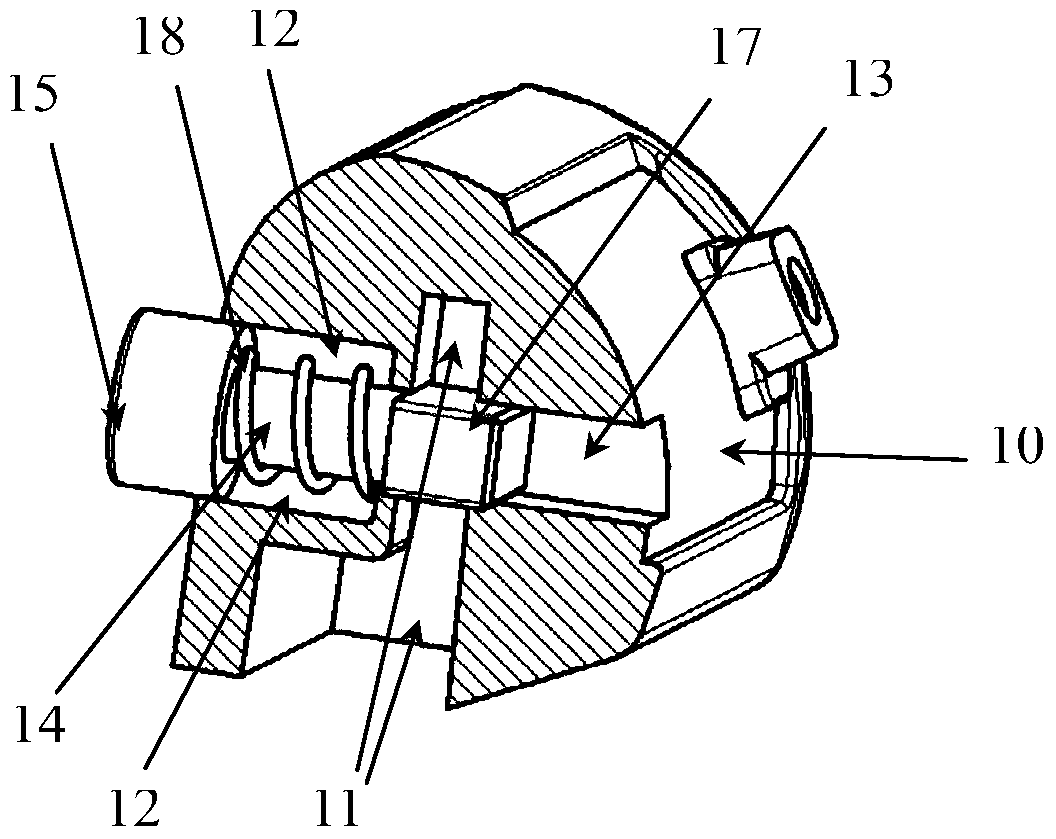

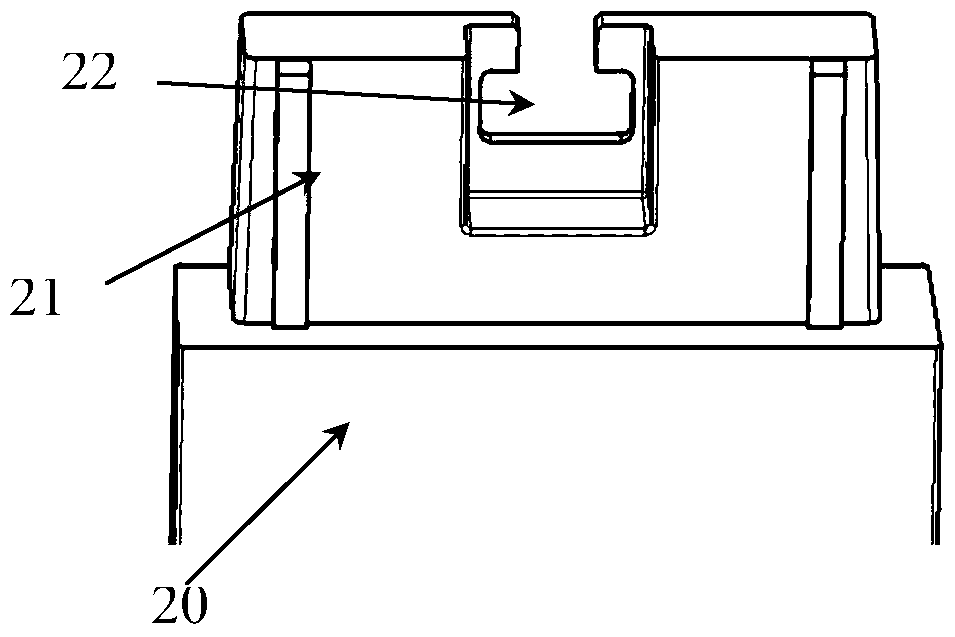

[0036] see also figure 2 , image 3 and Figure 4 , the bottom of the first connector 10 has a concave socket 11, the upper part of the second connector 20 has a connecting rod 21, the socket 11 is formed with the connecting rod 21 on the upper part of the second connector 20 Plug fit.

[0037] The top of the connecting rod 21 has a T-shaped, open connecting groove 22 ; the socket 11 of the first connecting member 10 is provided with a button insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com