Patents

Literature

85results about How to "Quick fix connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

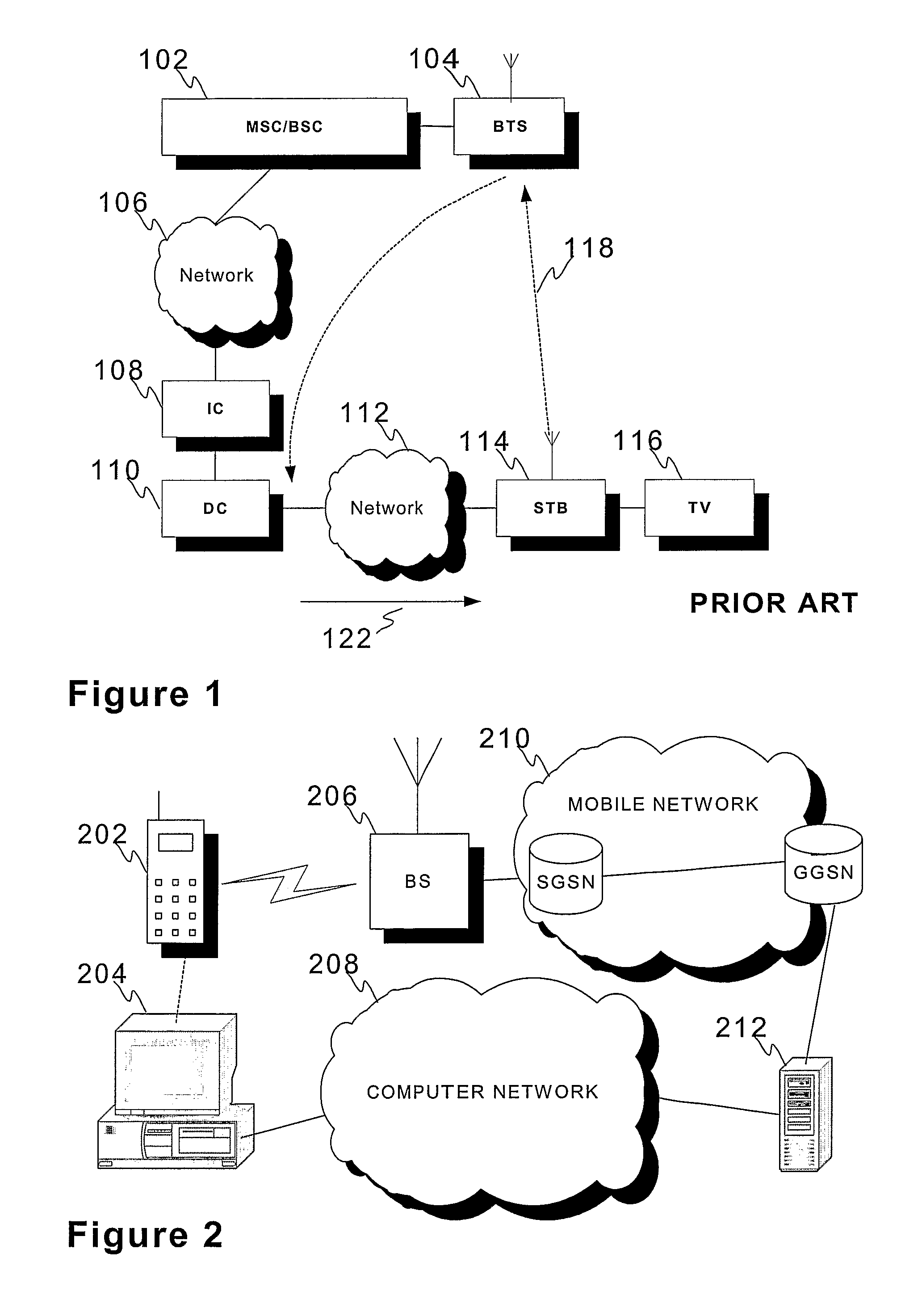

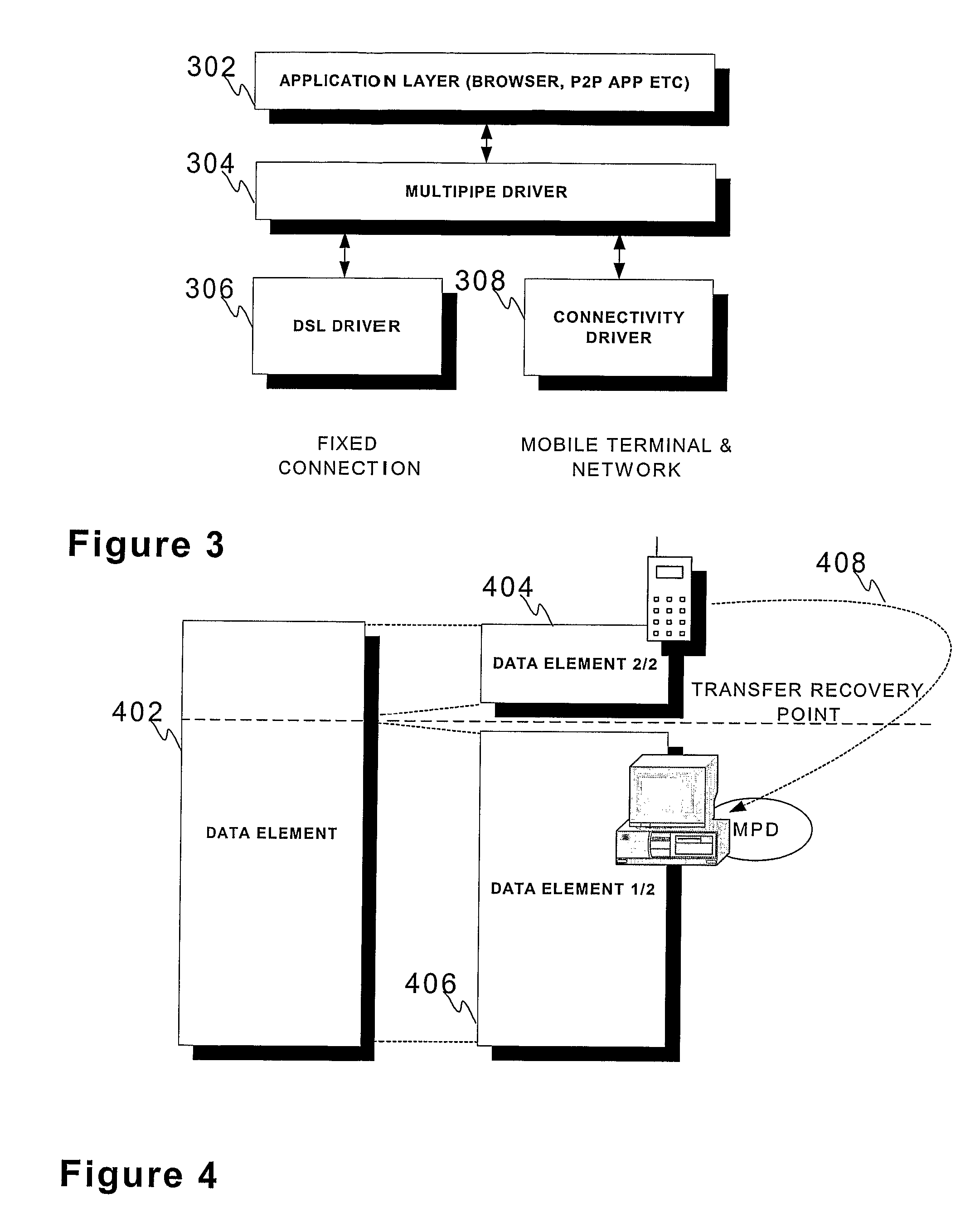

Method, a Device and a System for Transferring Data

InactiveUS20070280109A1Better use experienceEasy to adaptError preventionFrequency-division multiplex detailsData sourceCommunication device

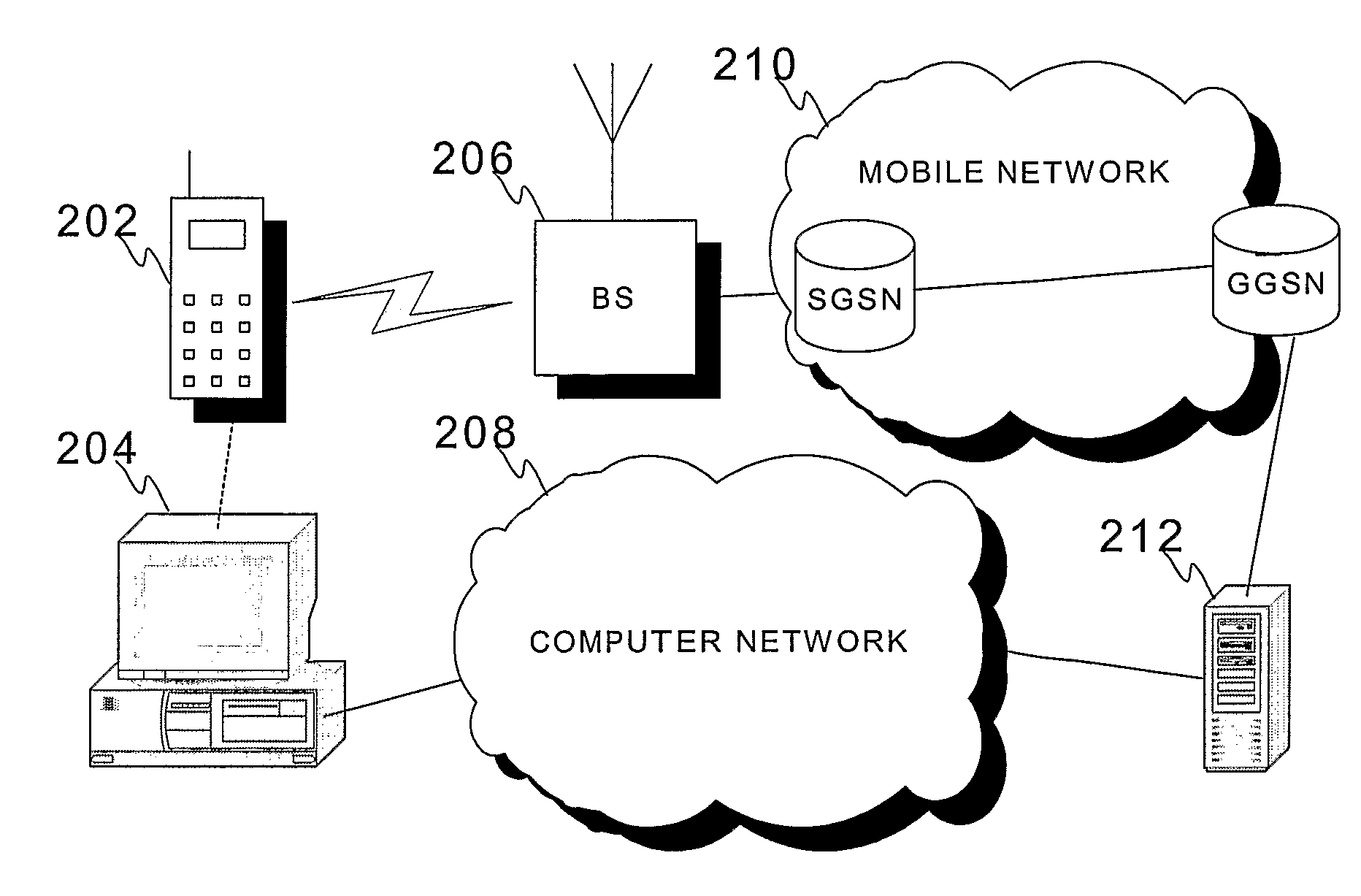

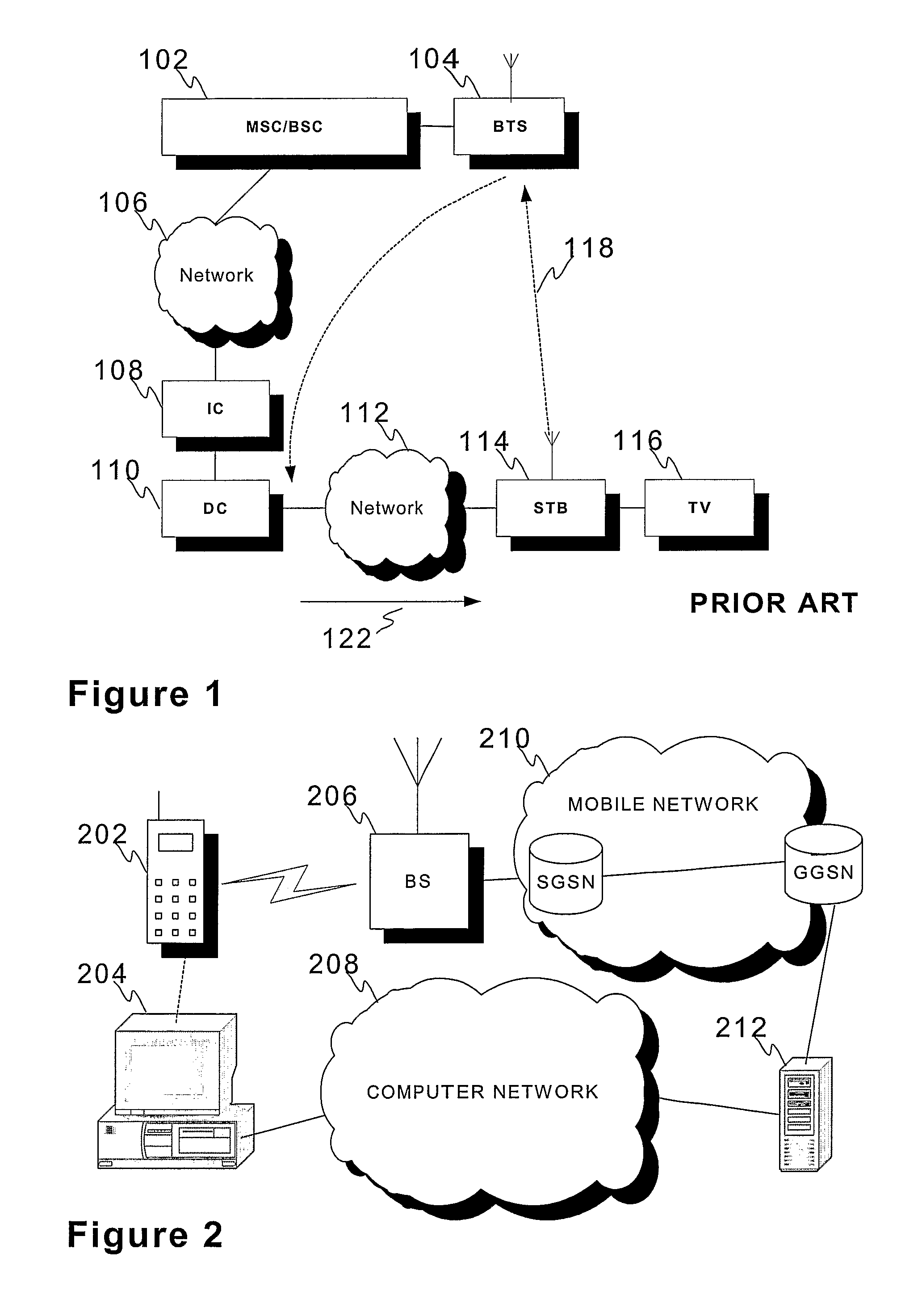

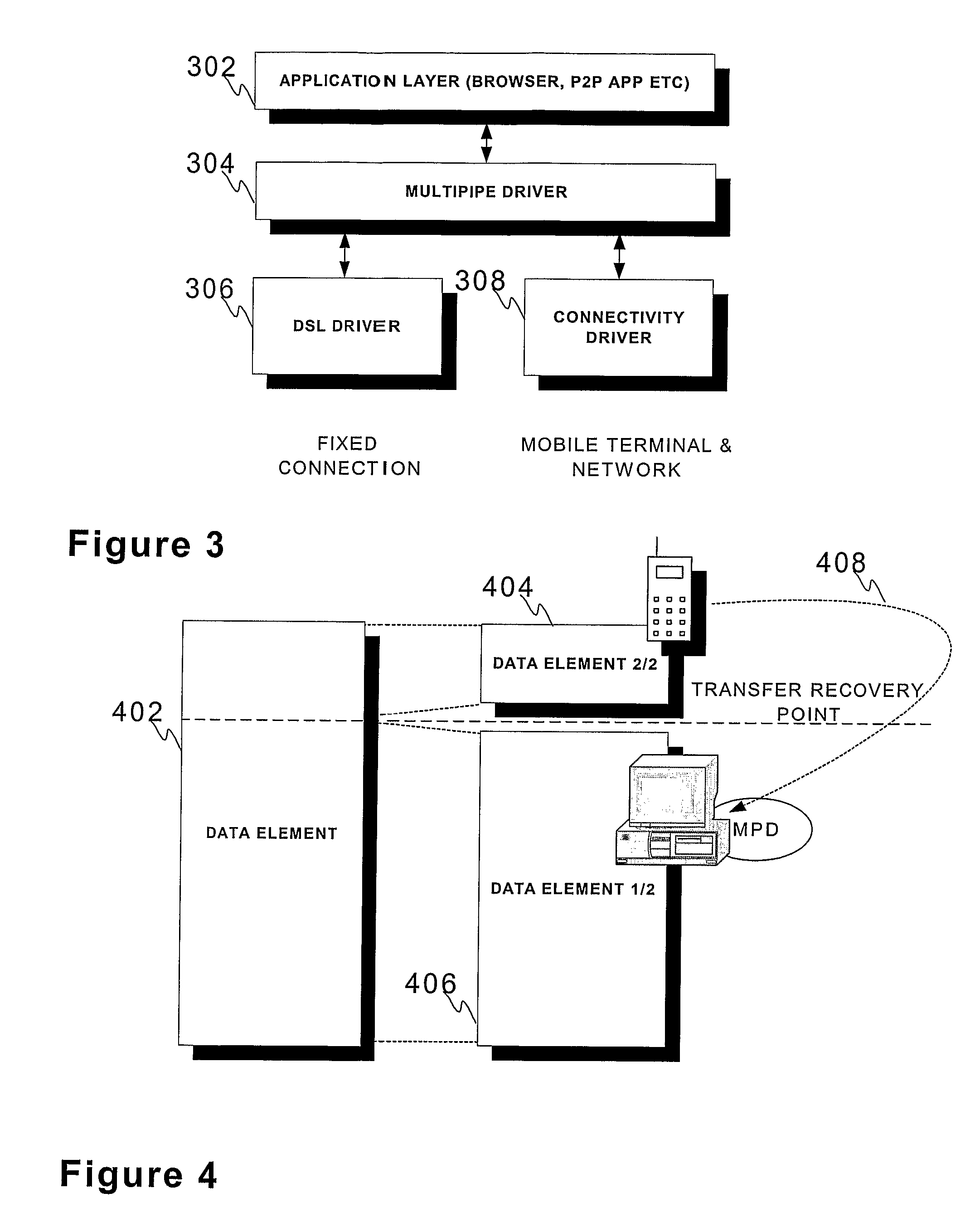

A method, a device and a system for transferring data from a data source (212) over both a wireless communications (210) and a fixed communications (208) network to a destination device (204) such that at least one portion of a data aggregate is transmitted through the wireless communications network (210) via a wireless communications device (202) and at least one another portion is transmitted through the fixed communications network (208). The destination device (204) may reconstruct the data aggregate by joining the received data portions together.

Owner:NOKIA CORP

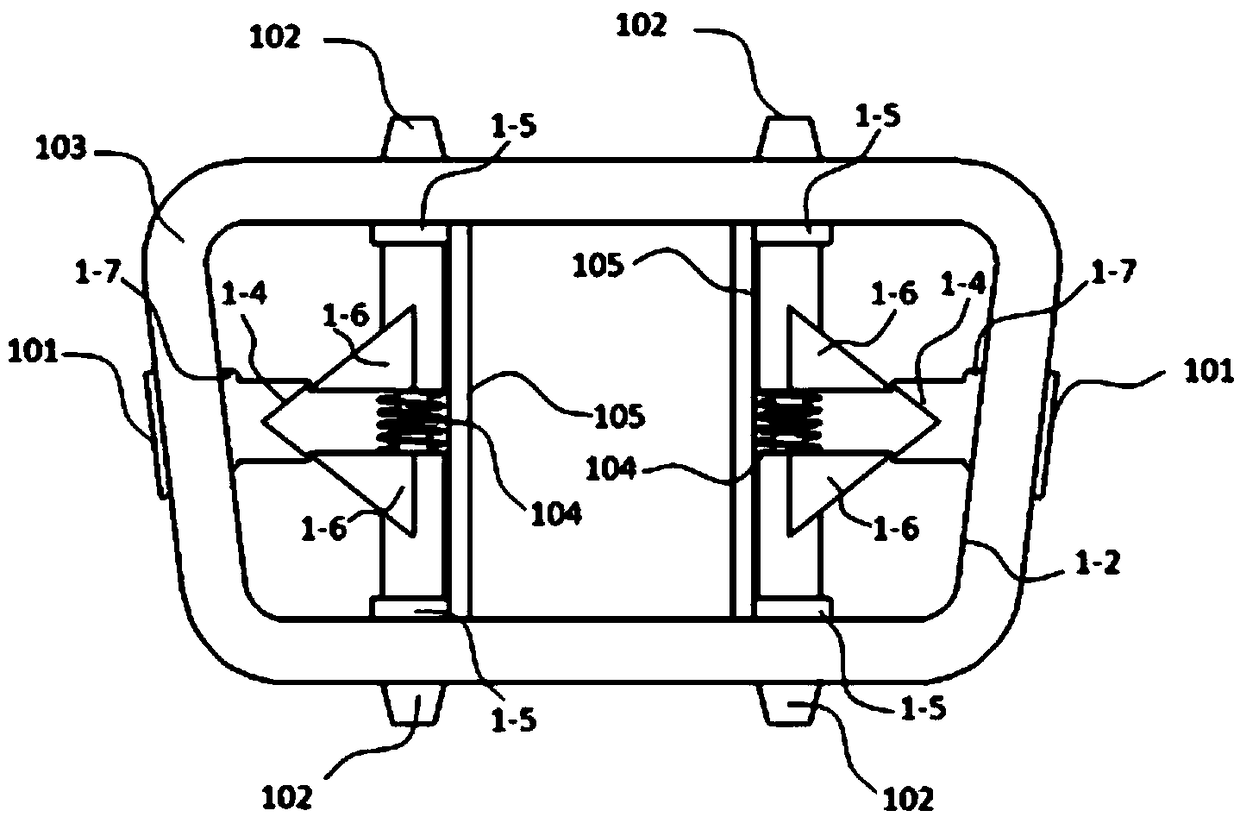

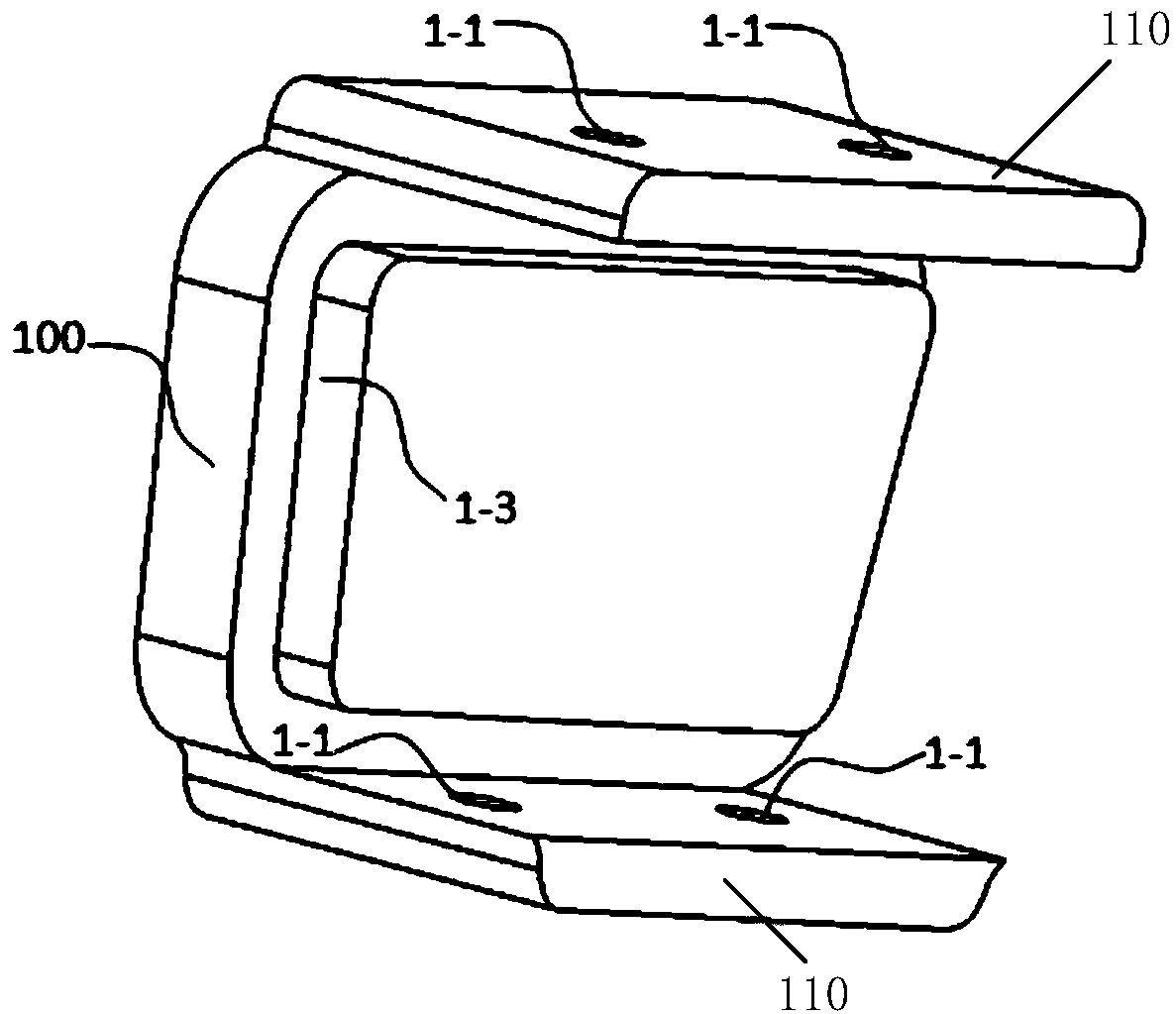

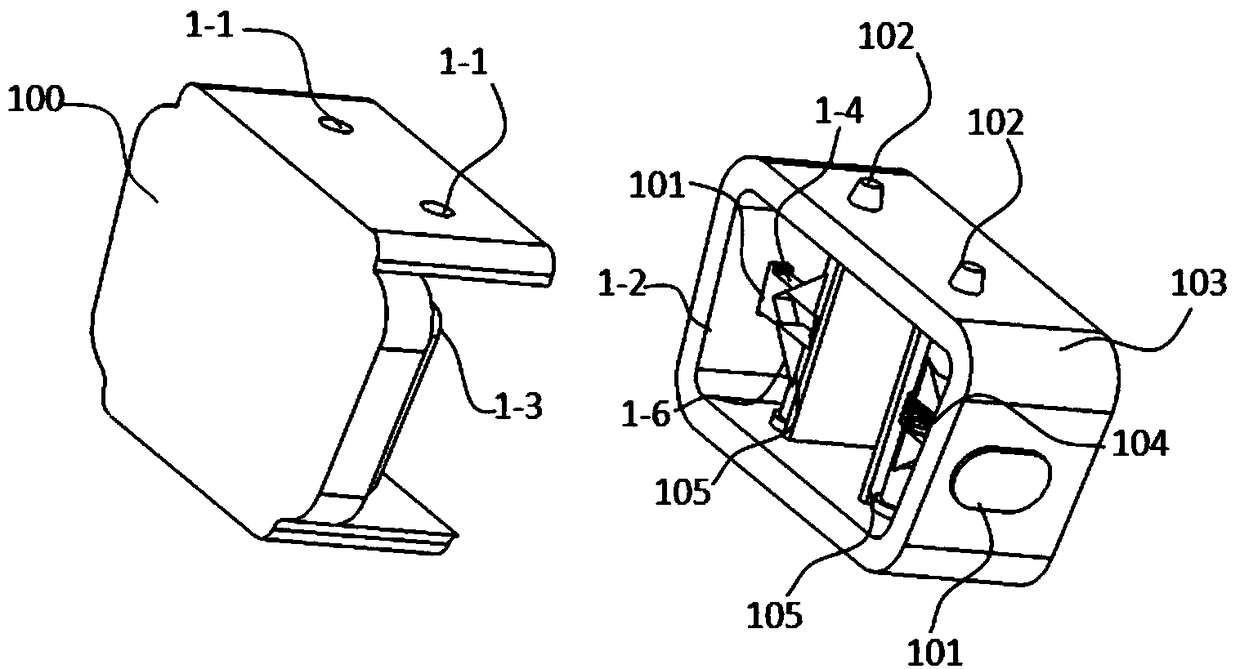

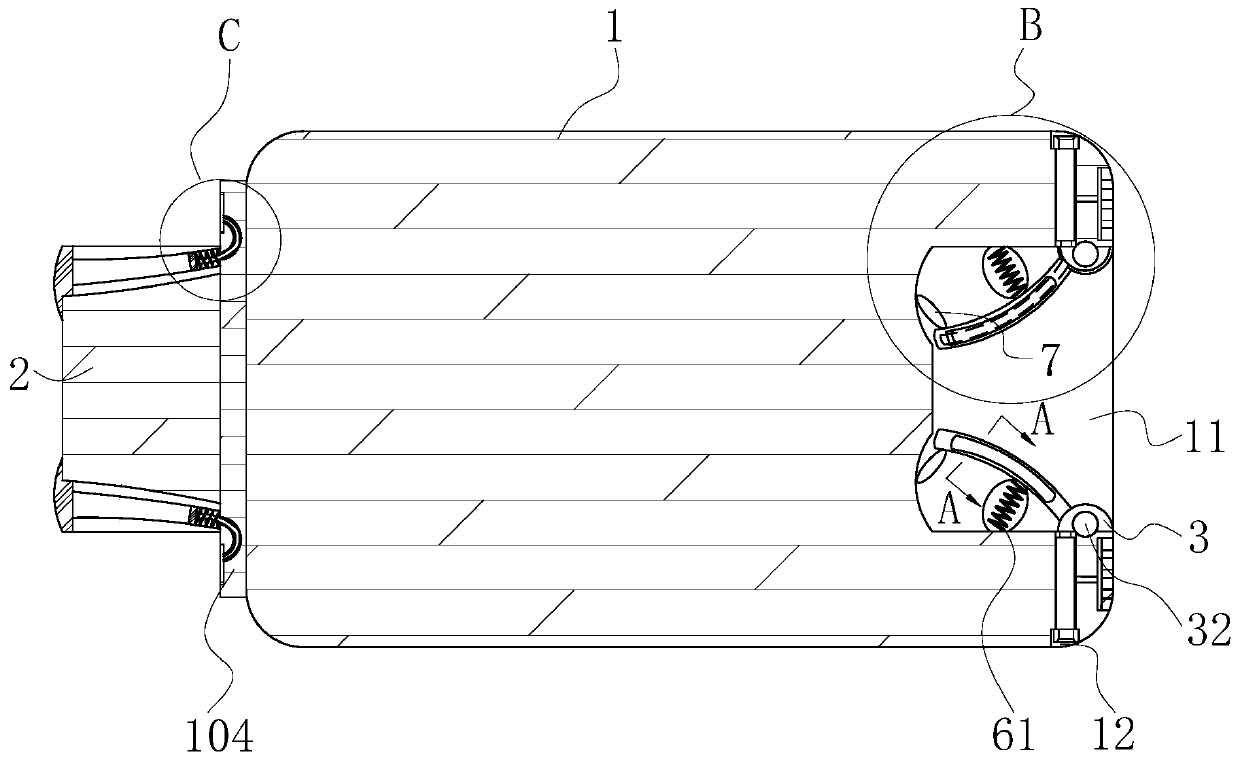

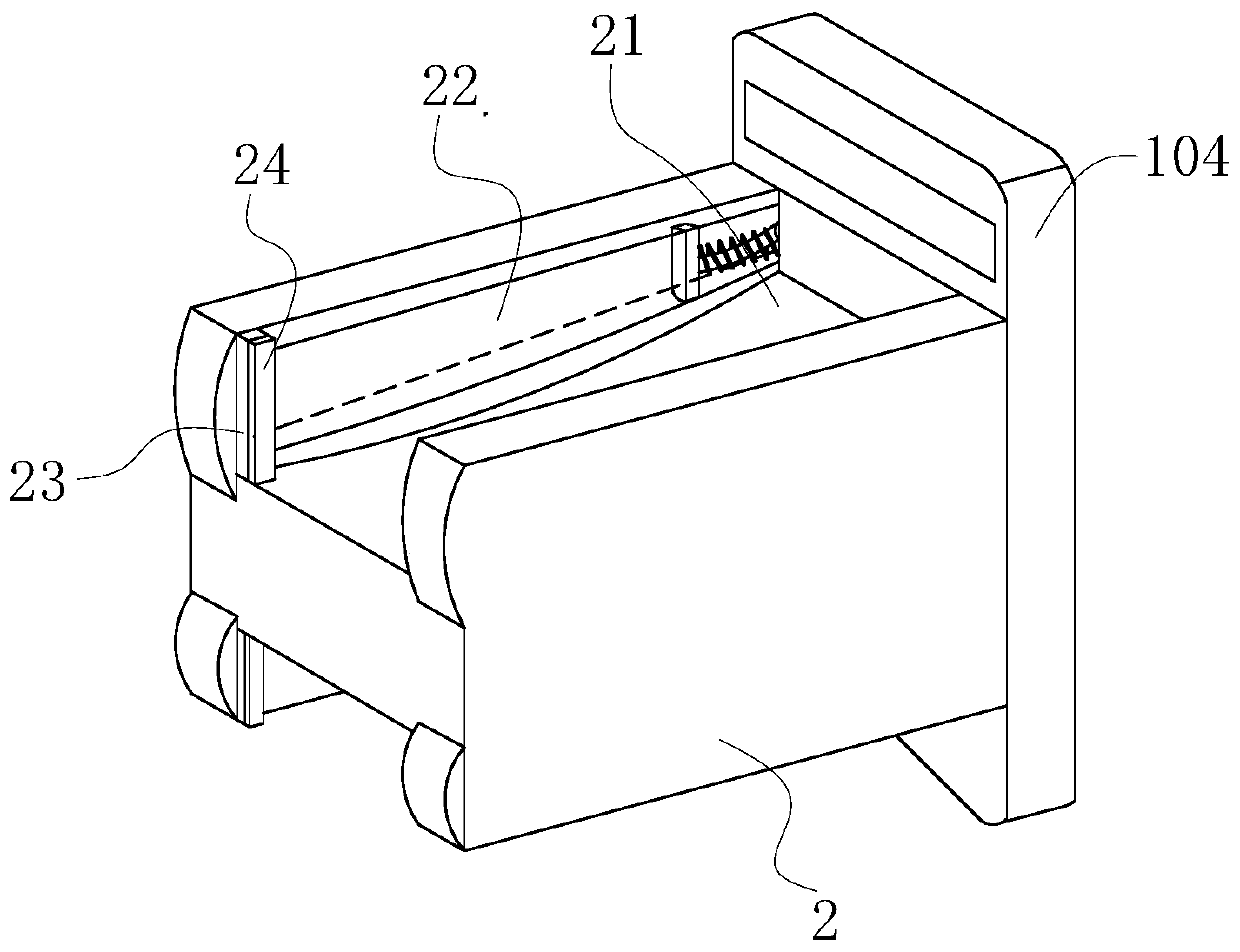

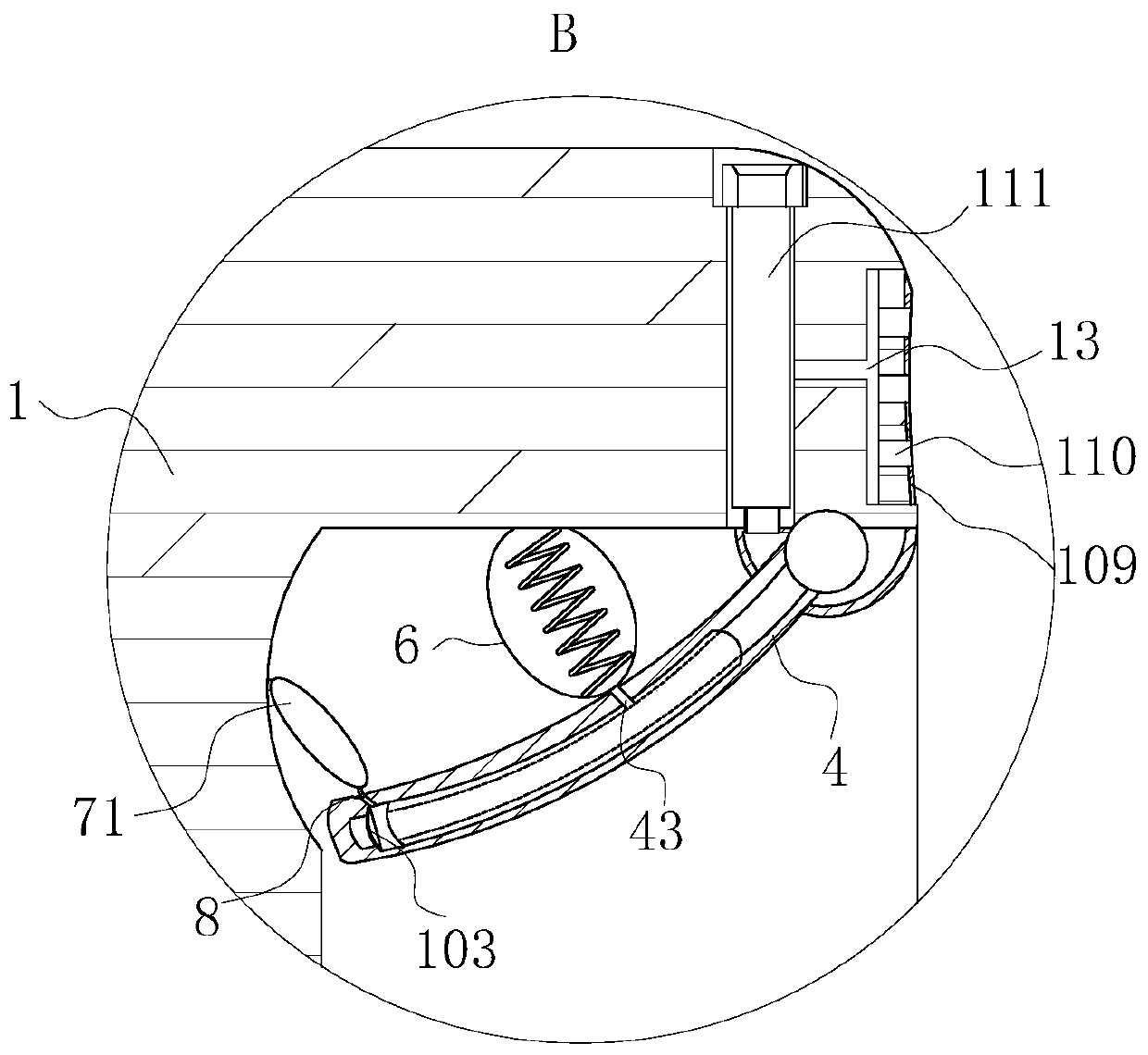

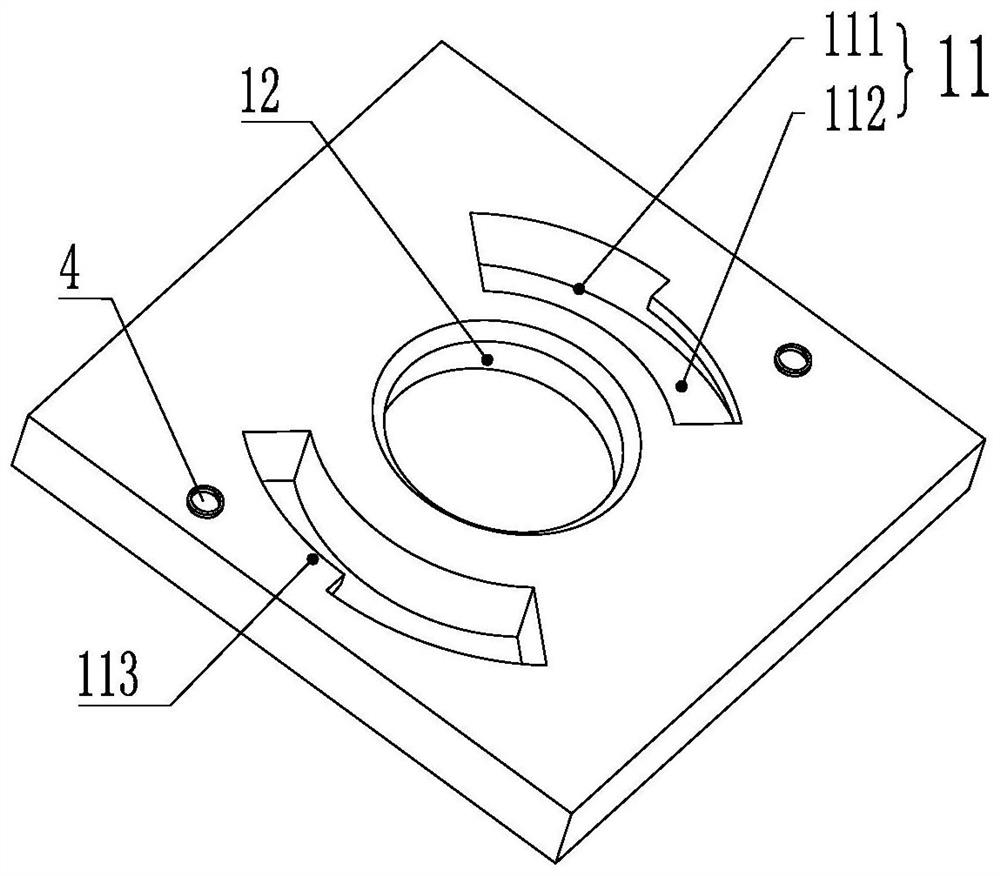

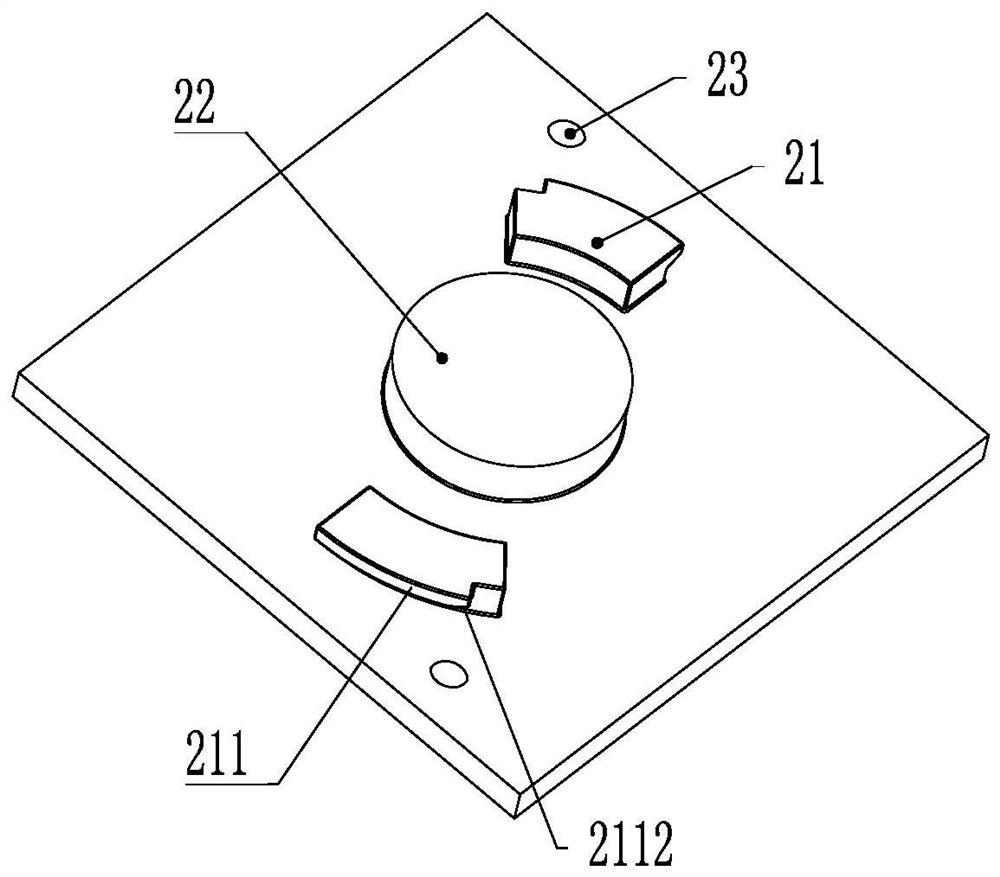

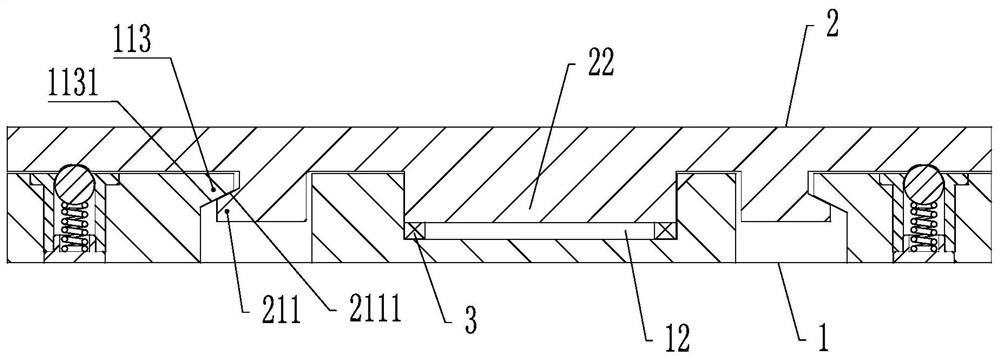

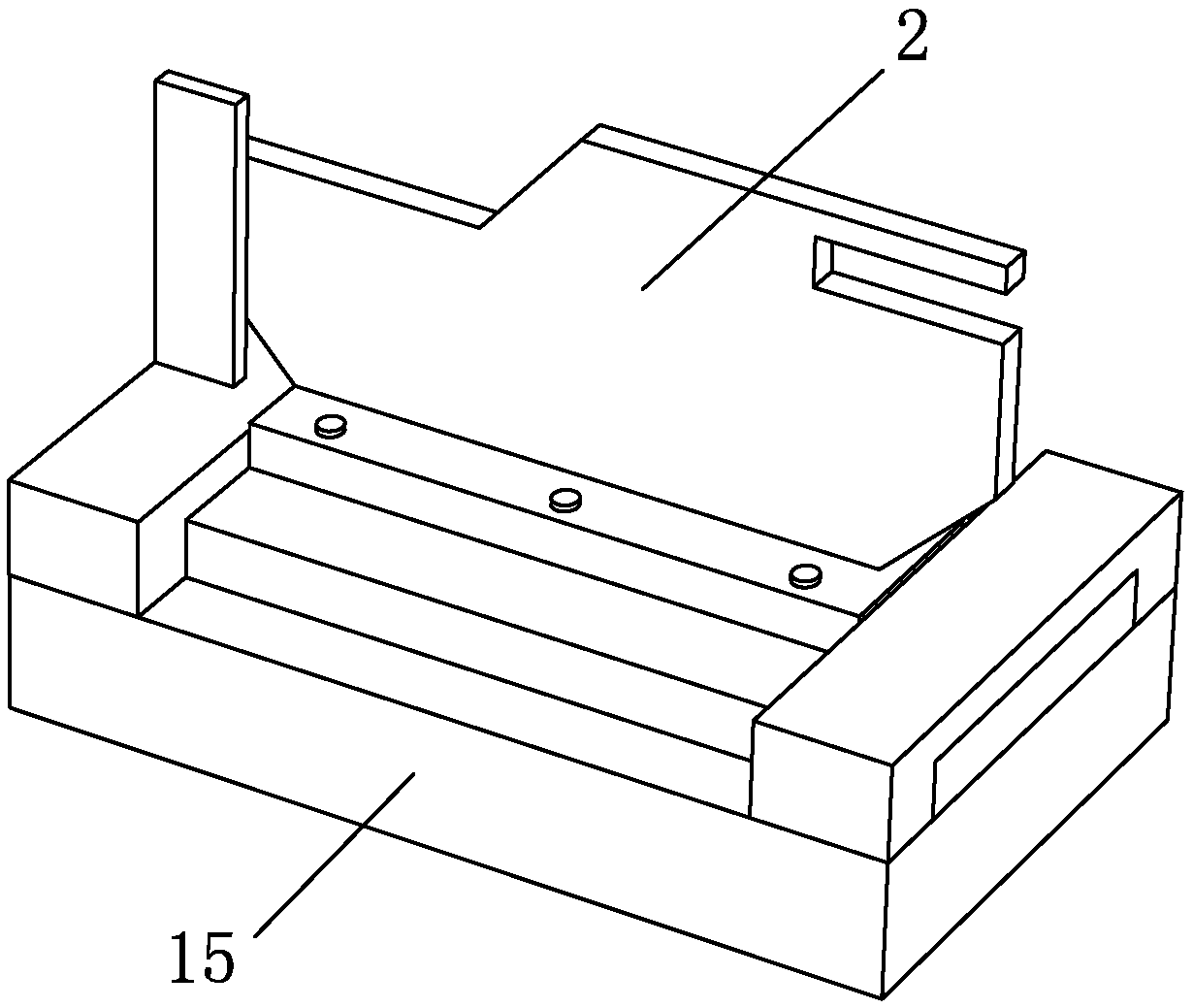

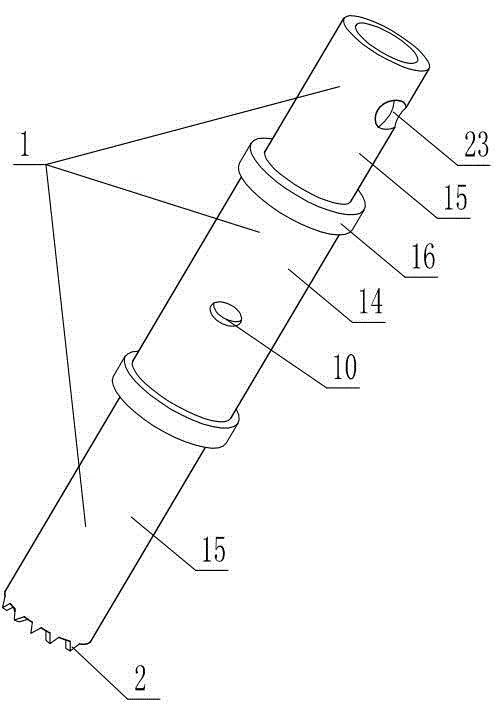

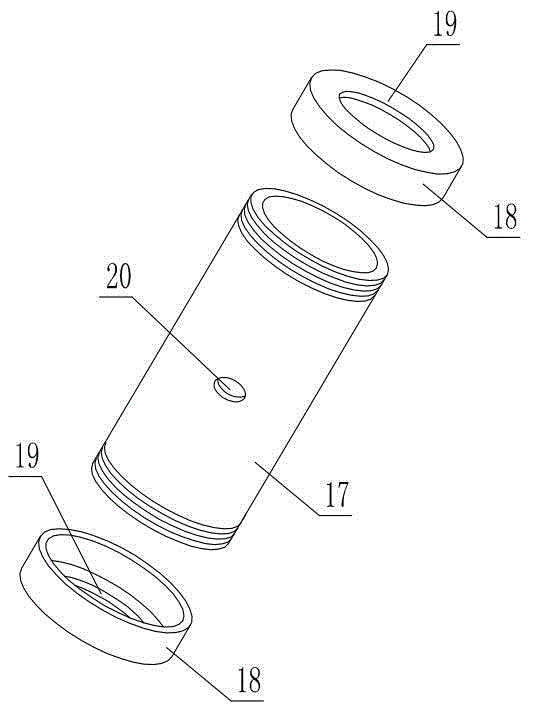

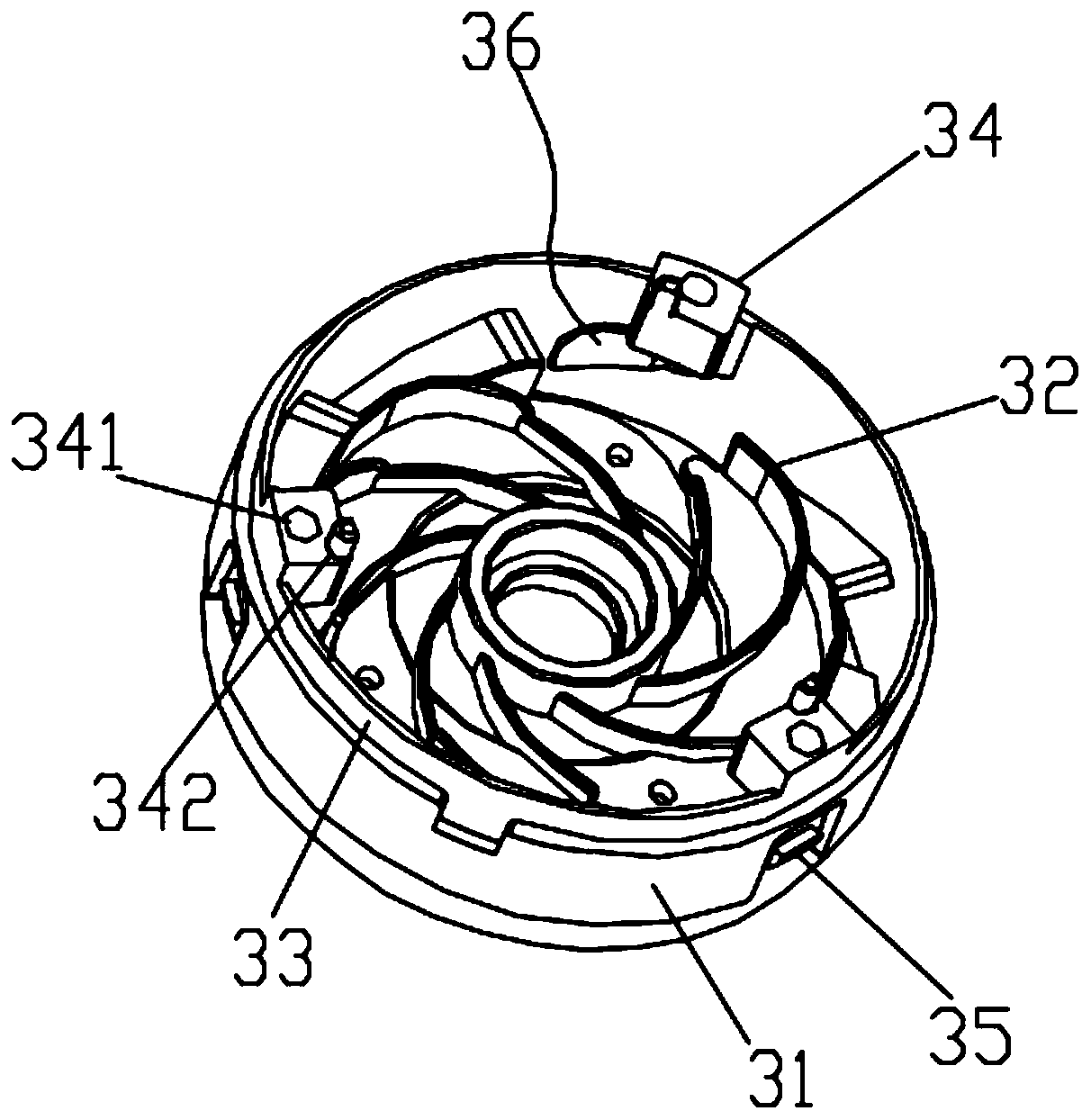

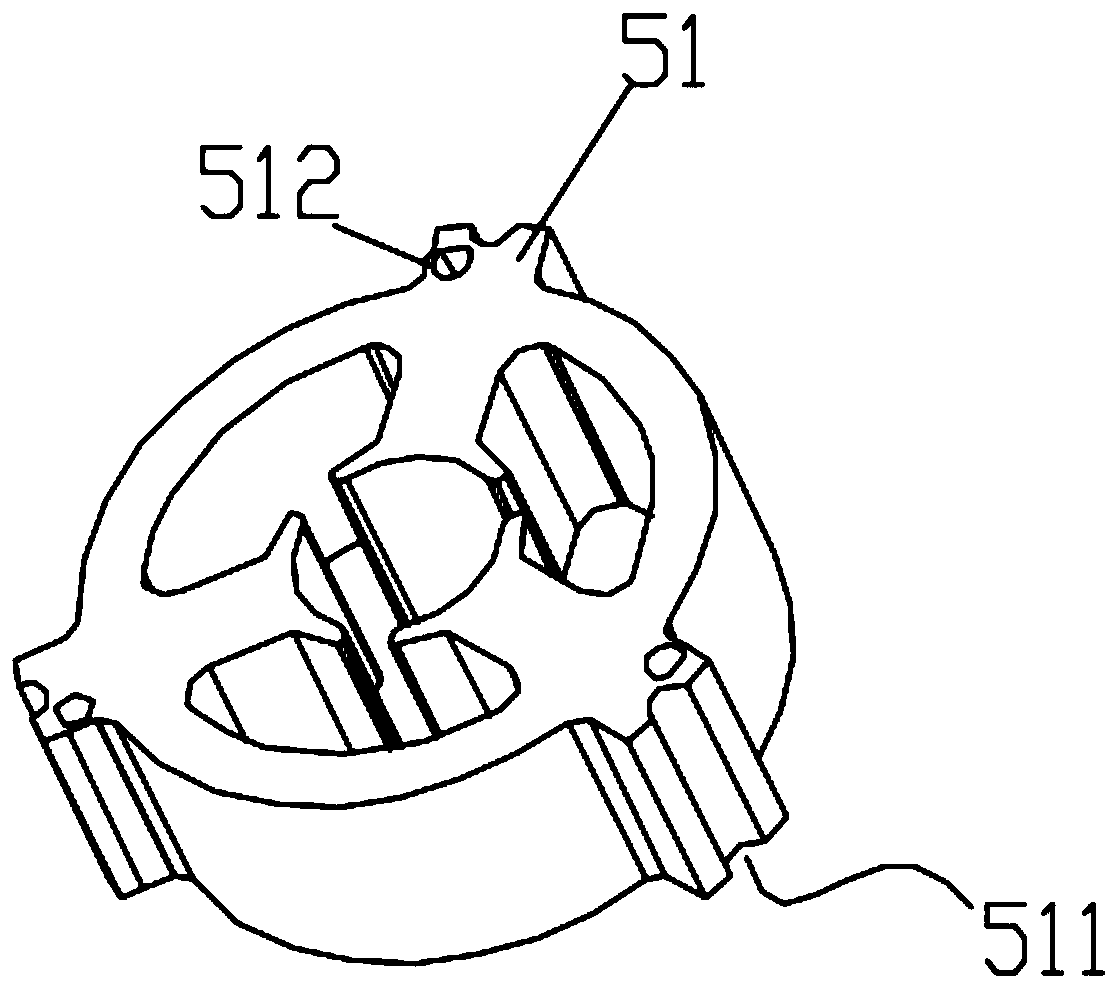

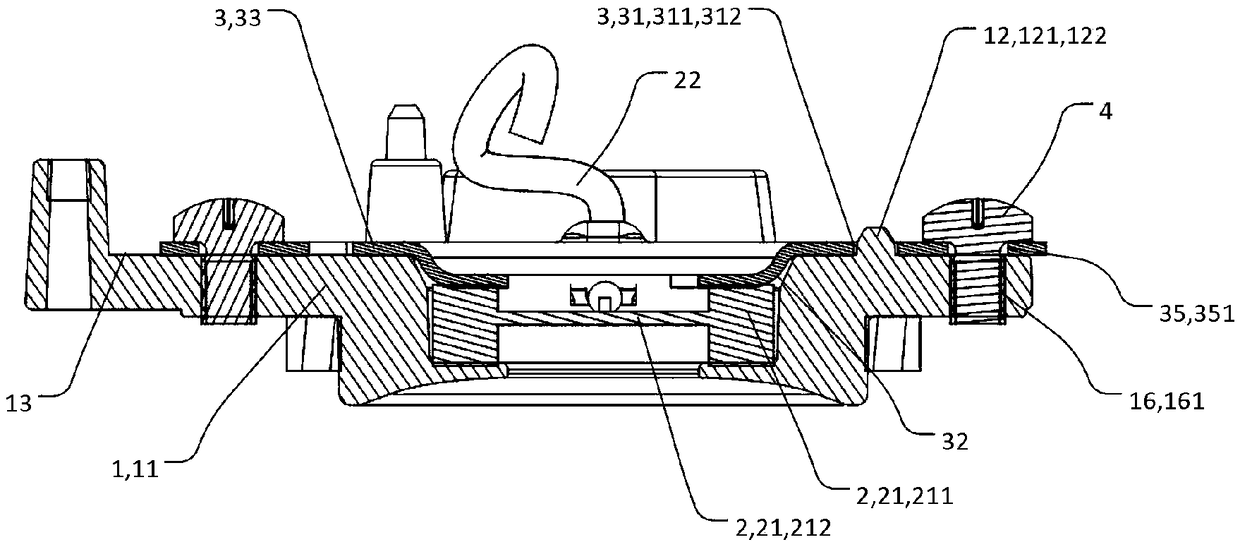

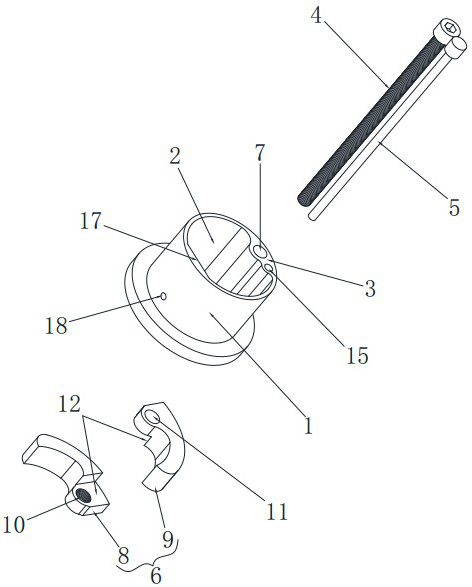

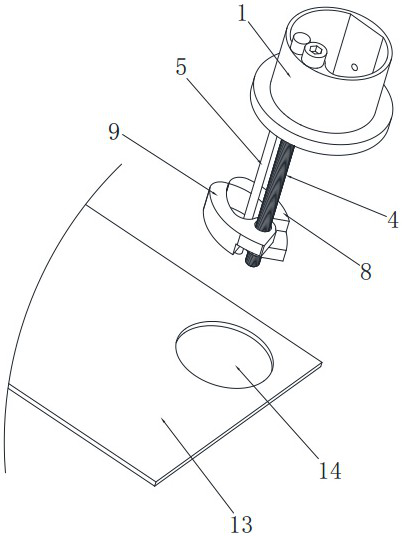

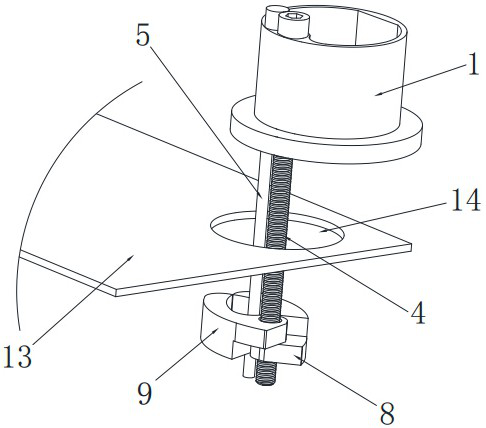

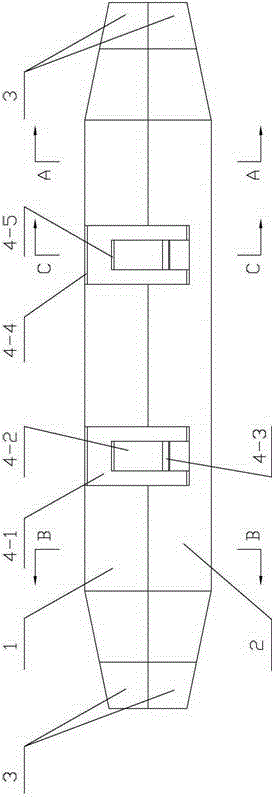

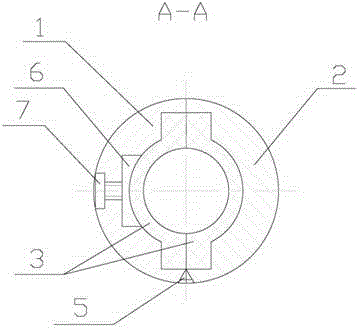

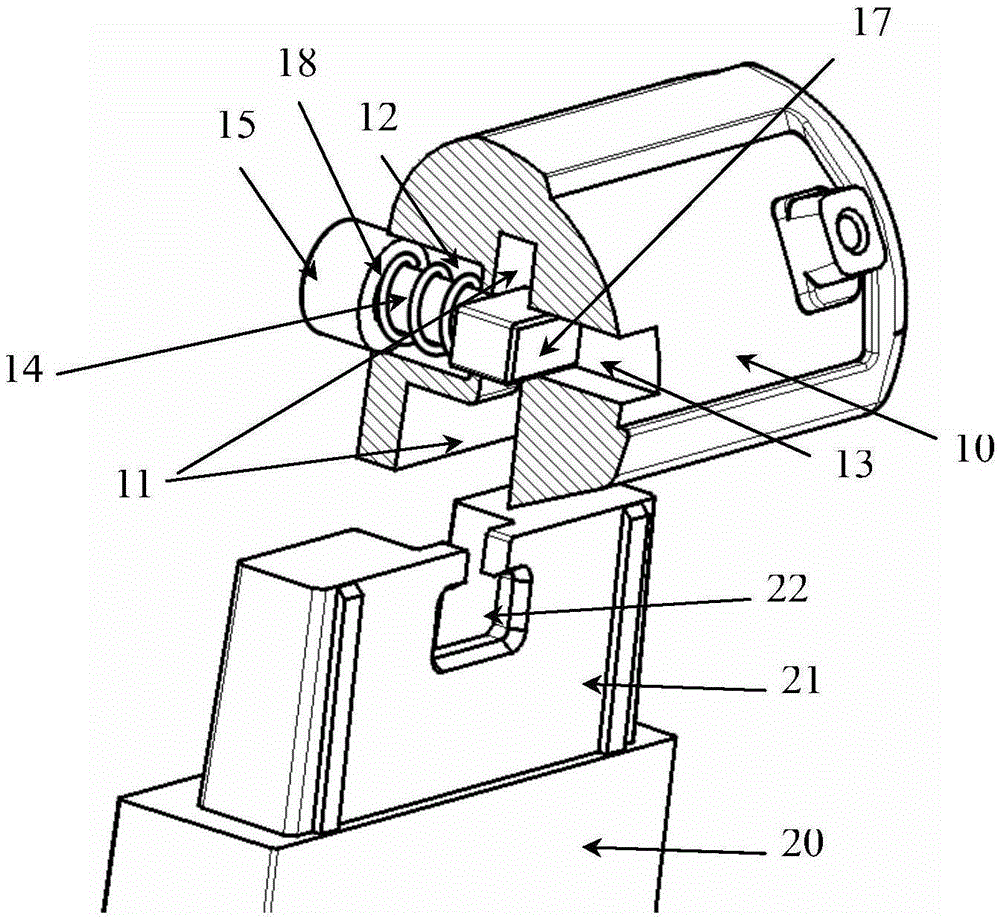

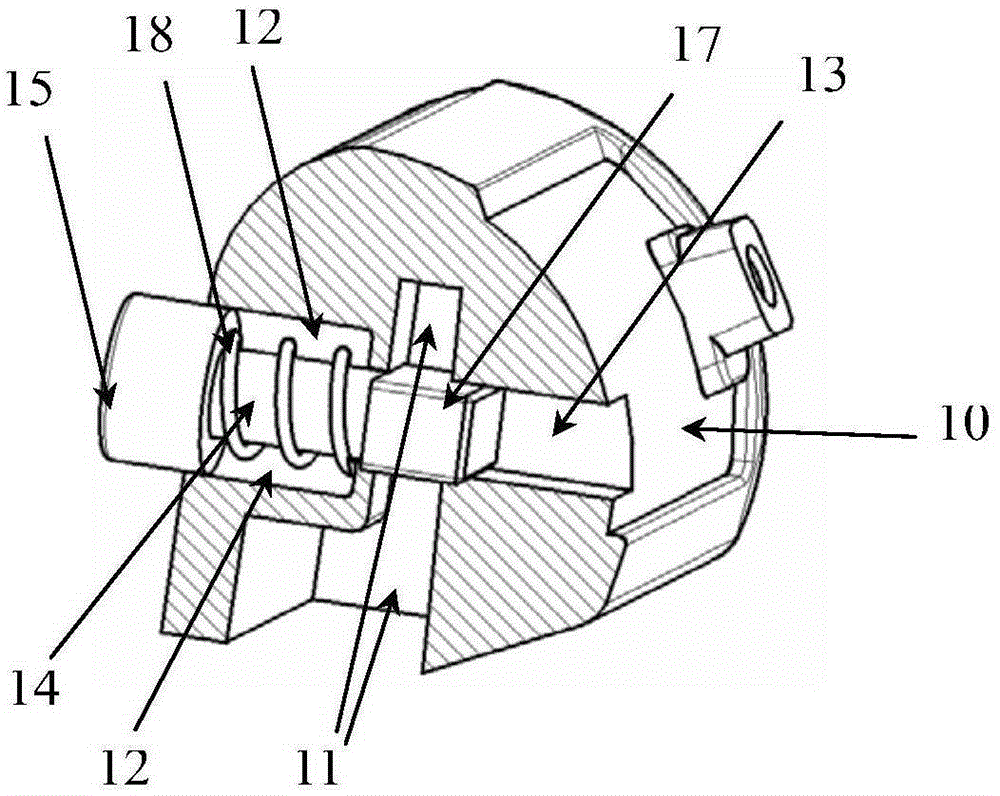

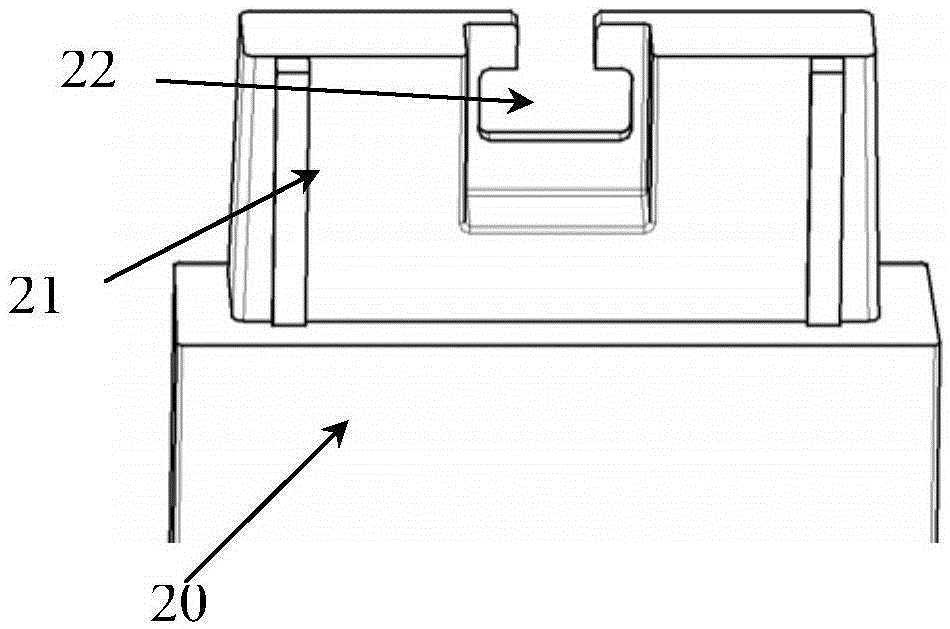

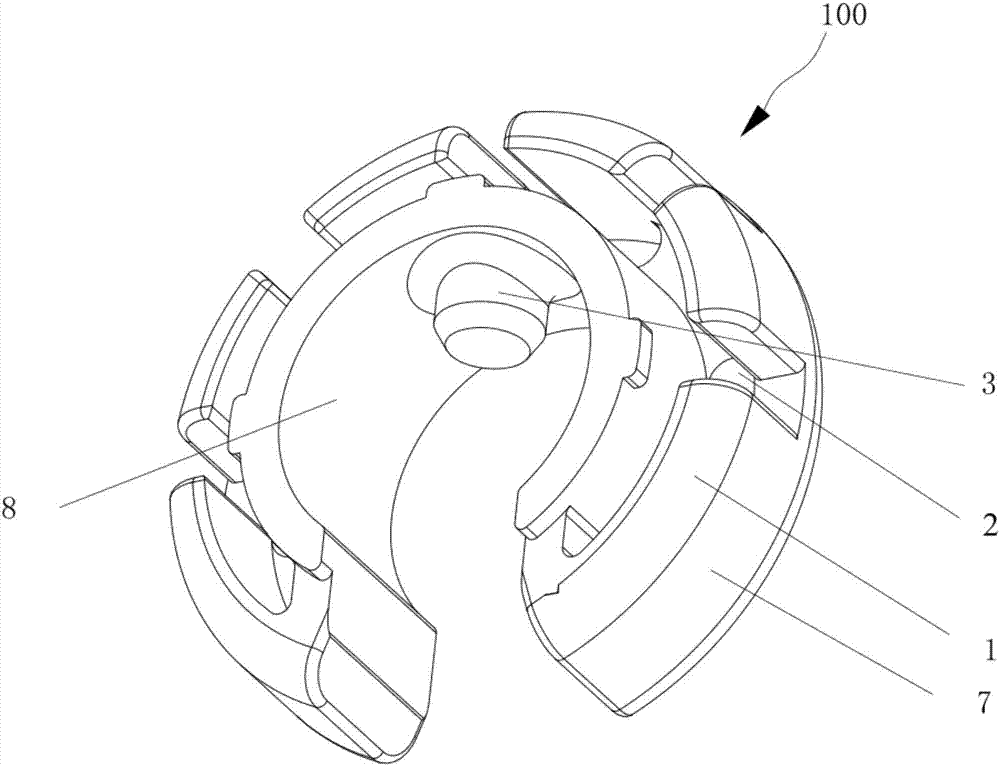

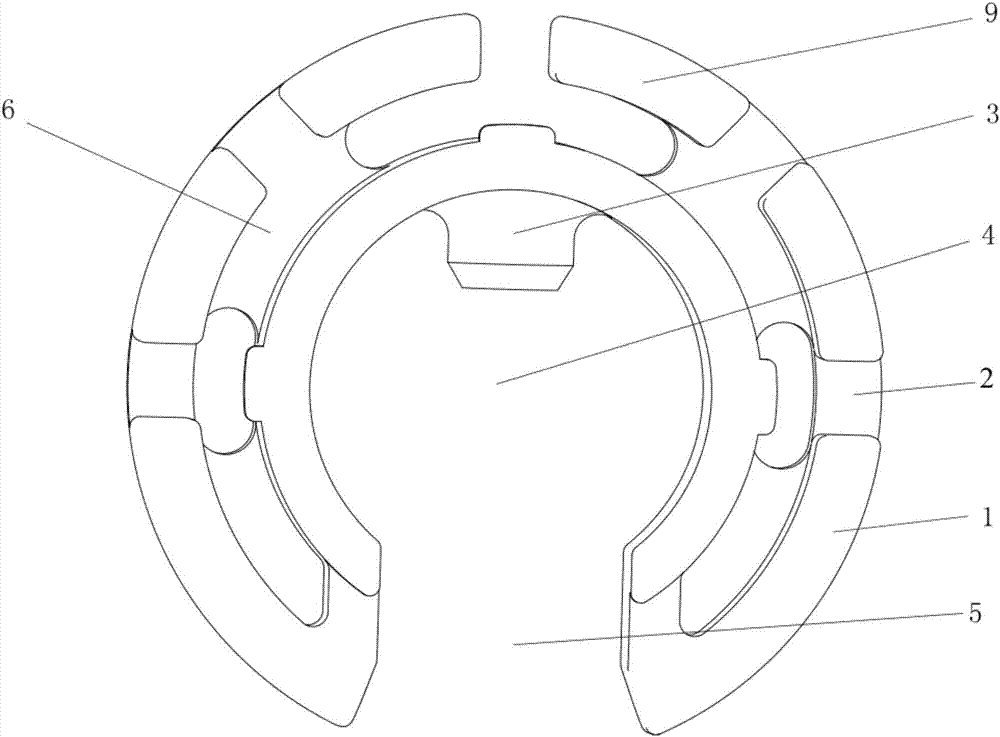

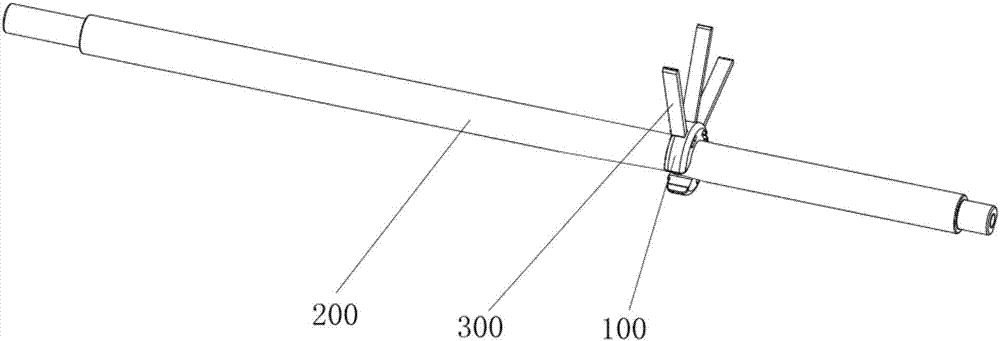

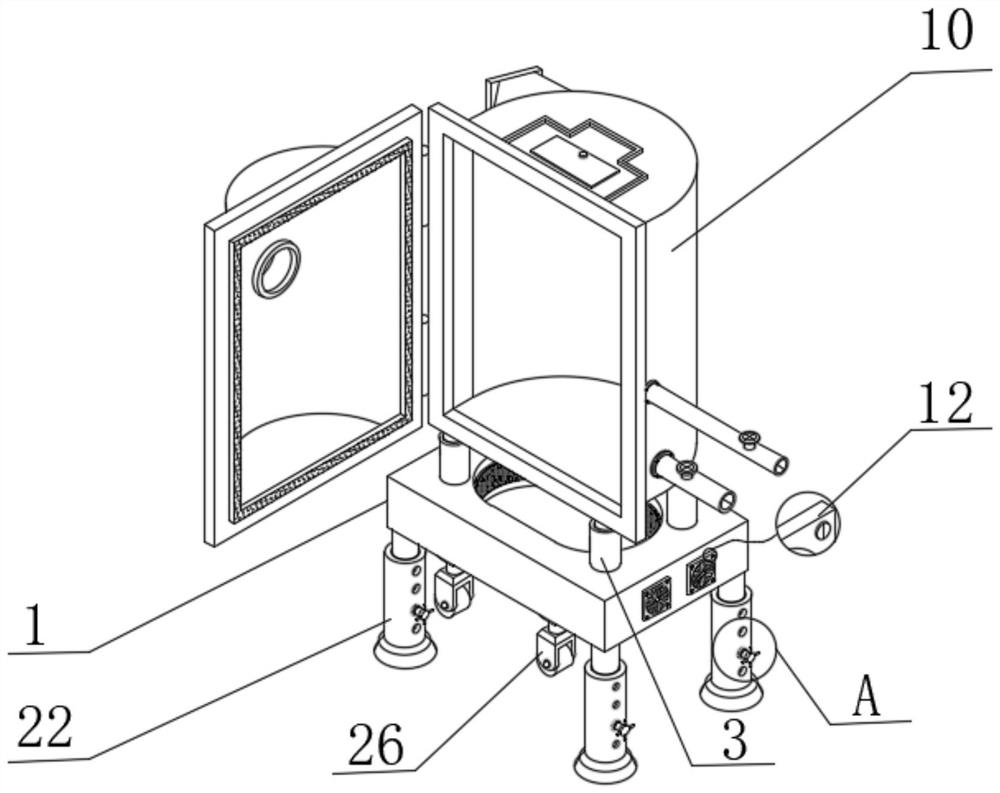

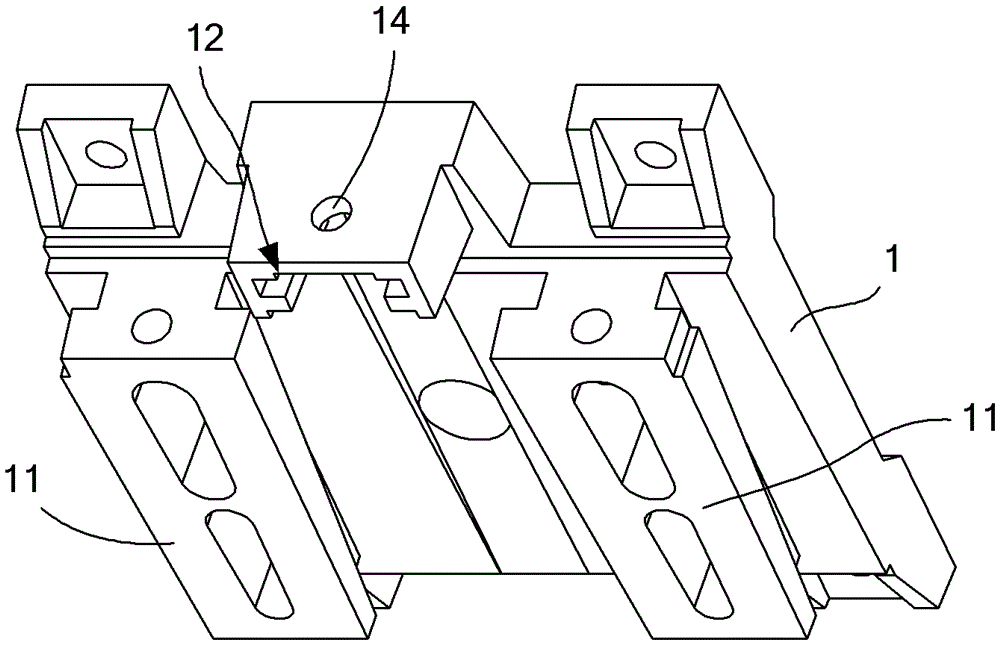

A quick changing device for a surgical instrument

ActiveCN109171966AQuick installationQuick releaseSurgical manipulatorsSurgical robotsLocking mechanismEngineering

The invention relates to a quick changing device for a surgical instrument, which realizes quick connection and disassembly between the surgical instrument and the end of a robot arm. The quick changing device comprises a mounting base, a mounting joint, a positioning mechanism and a locking mechanism. The positioning mechanism comprises a first positioning part and a second positioning part matching the same, wherein the first positioning part and the second positioning part are respectively arranged on the mounting base and the mounting joint; the locking mechanism includes a first connectordisposed on the mounting joint, and a control device and a second connector disposed on the mounting base. The control device is configured to control the second connector to be locked with the firstconnector so that the first positioning portion and the second positioning portion remain in mating contact, thereby realizing the assembly between the mounting joint and the mounting base. The control device is further configured to control the second connection member and the first connection member to be unlocked so that the first positioning portion and the second positioning portion are in adetachable state, thereby realizing unloading between the mounting joint and the mounting base.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

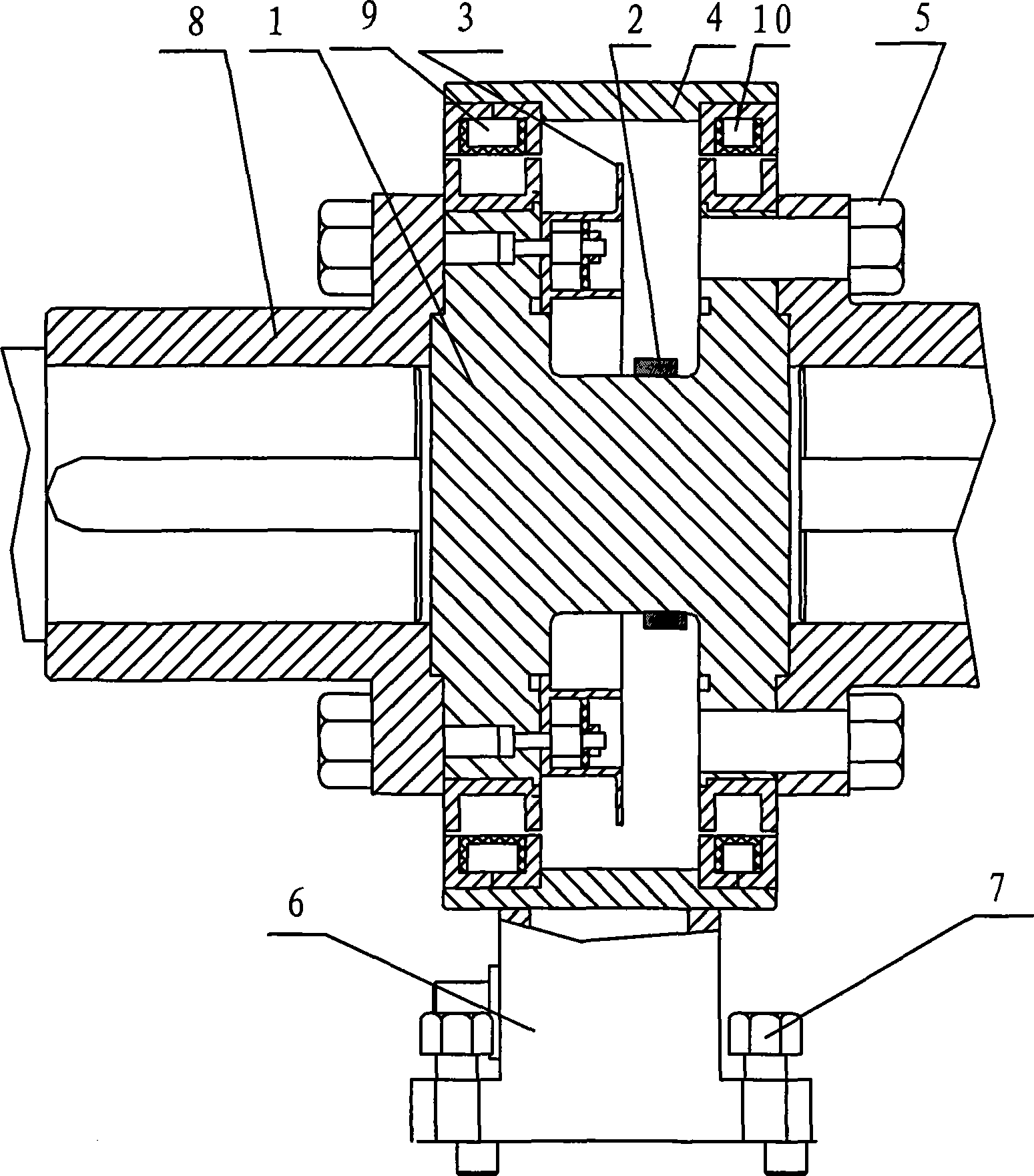

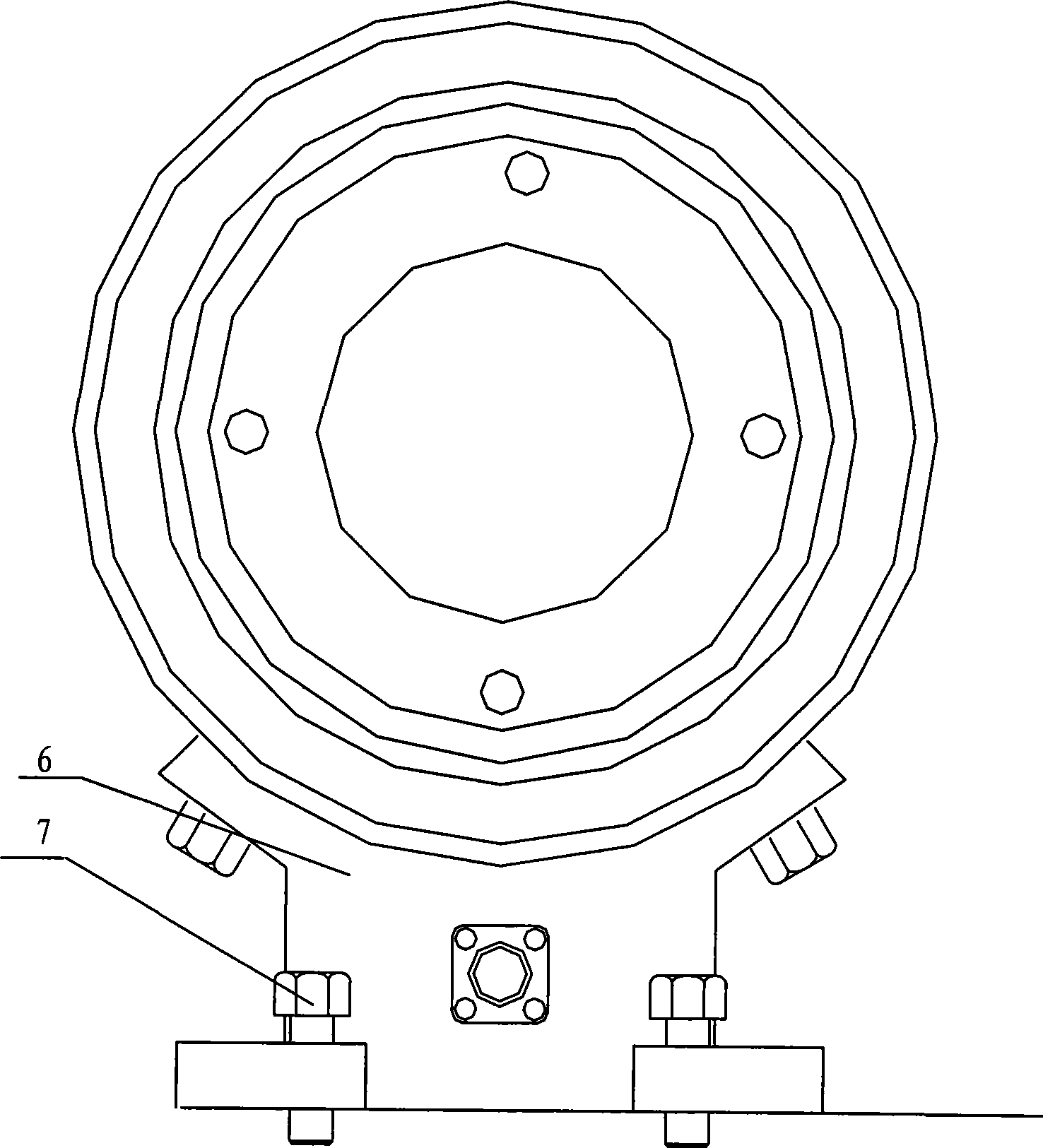

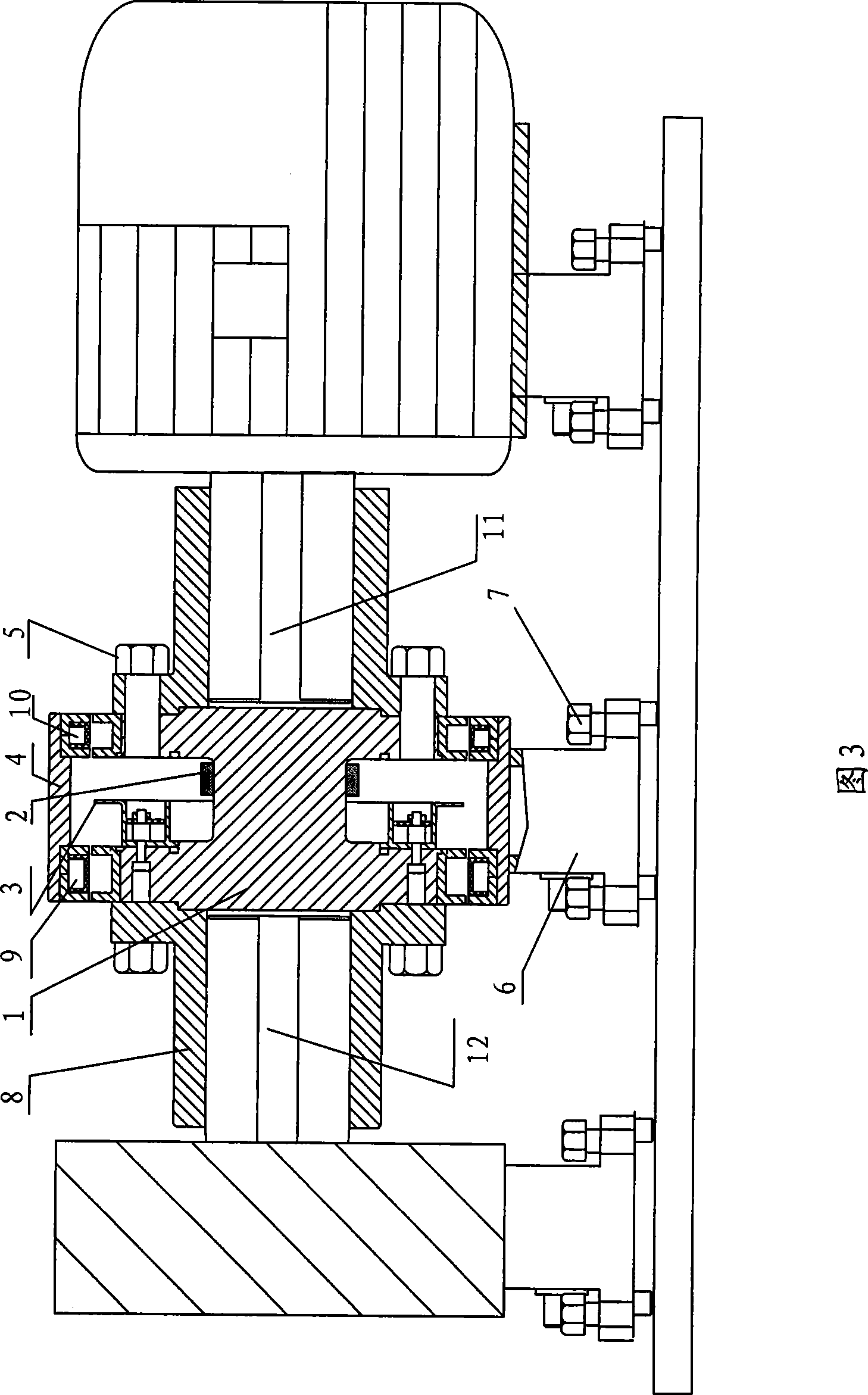

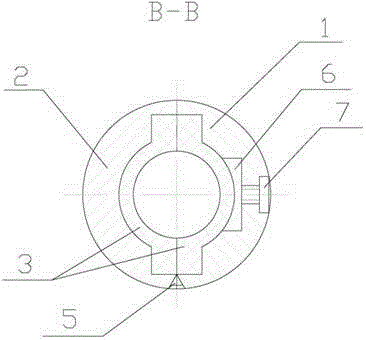

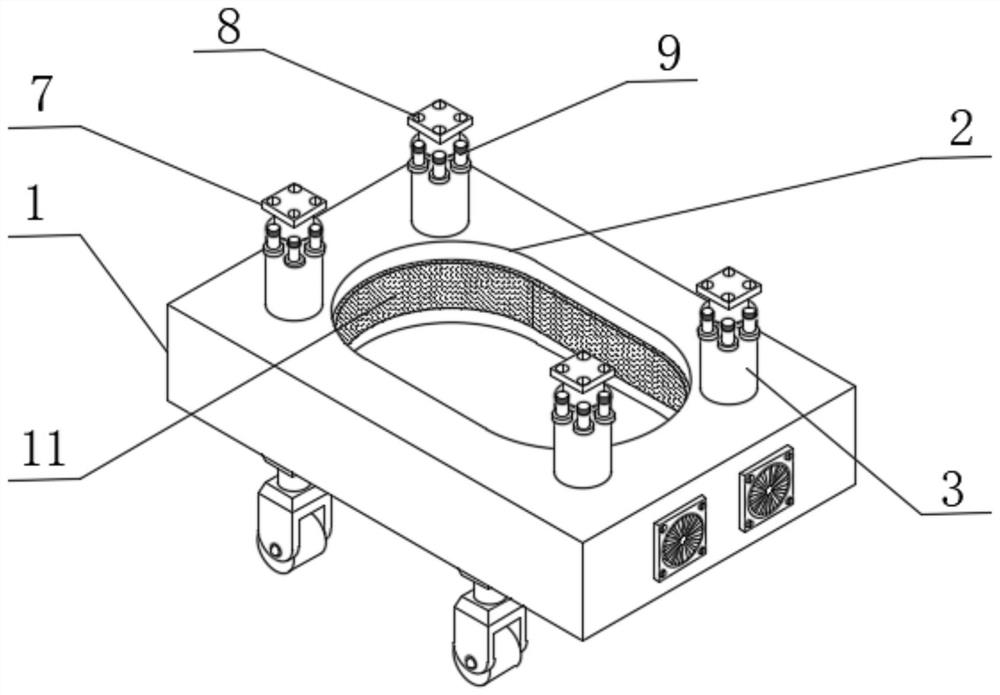

Torque sensor and measuring system

InactiveCN101382461ASimple processEasy to operateWork measurementLinear/angular speed measurementTorque sensorPower equipment

The invention relates to a torque sensor which comprises a flanged shaft and a stress sensor, wherein, the two end faces of the flanged shaft are provided with ring flanges so as to be used for fixedly connecting a rotating shaft of power equipment or the rotating shaft of a load. The invention also relates to a measuring system of the torque sensor, which comprises the load, the torque sensor and the power equipment which are sequentially connected, a coupling on the torque sensor fixedly connects the rotating shaft of the power equipment and the rotating shaft of the load. By arranging the ring flanges on the end faces of the torque sensor, on the one hand, distance dimension along the axial direction is shortened, axial stability is improved, the sensor is suitable for working conditions with special dimension and is more suitable for the occasions of high speed and super high speed due to the avoidance of the use of a bearing, and the application is wider; on the other hand, the installation process is simpler and is convenient for operation.

Owner:北京新宇航测控科技股份有限公司 +1

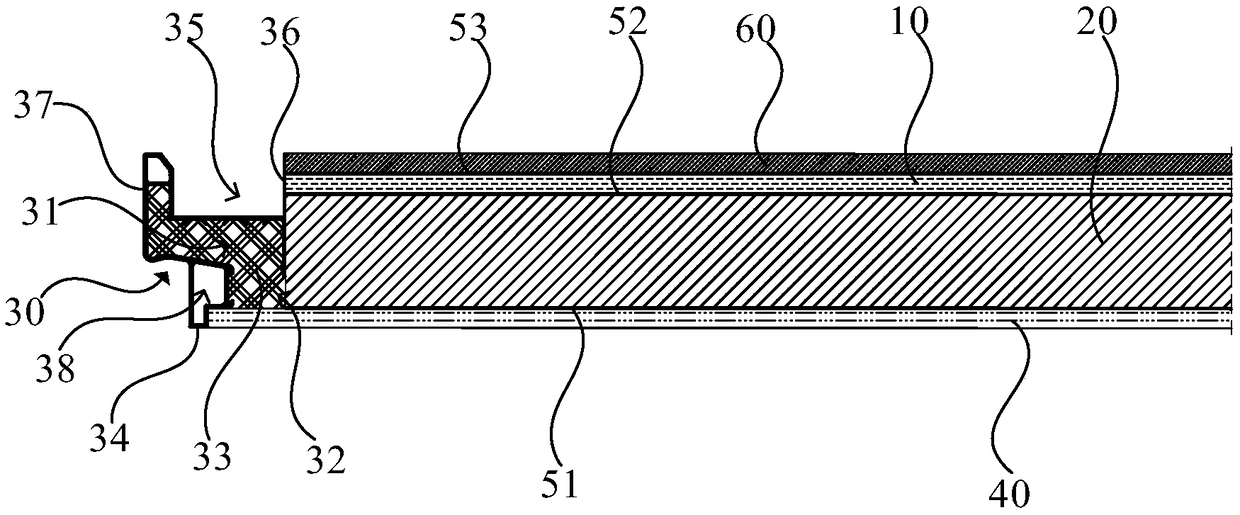

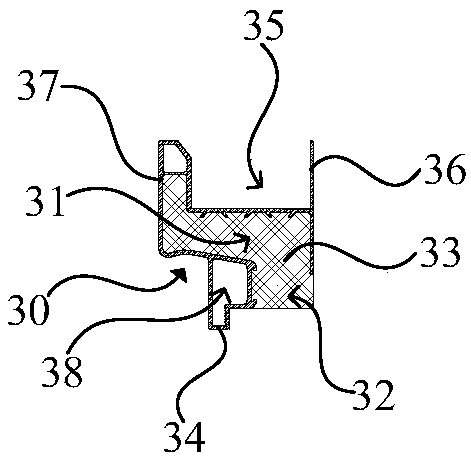

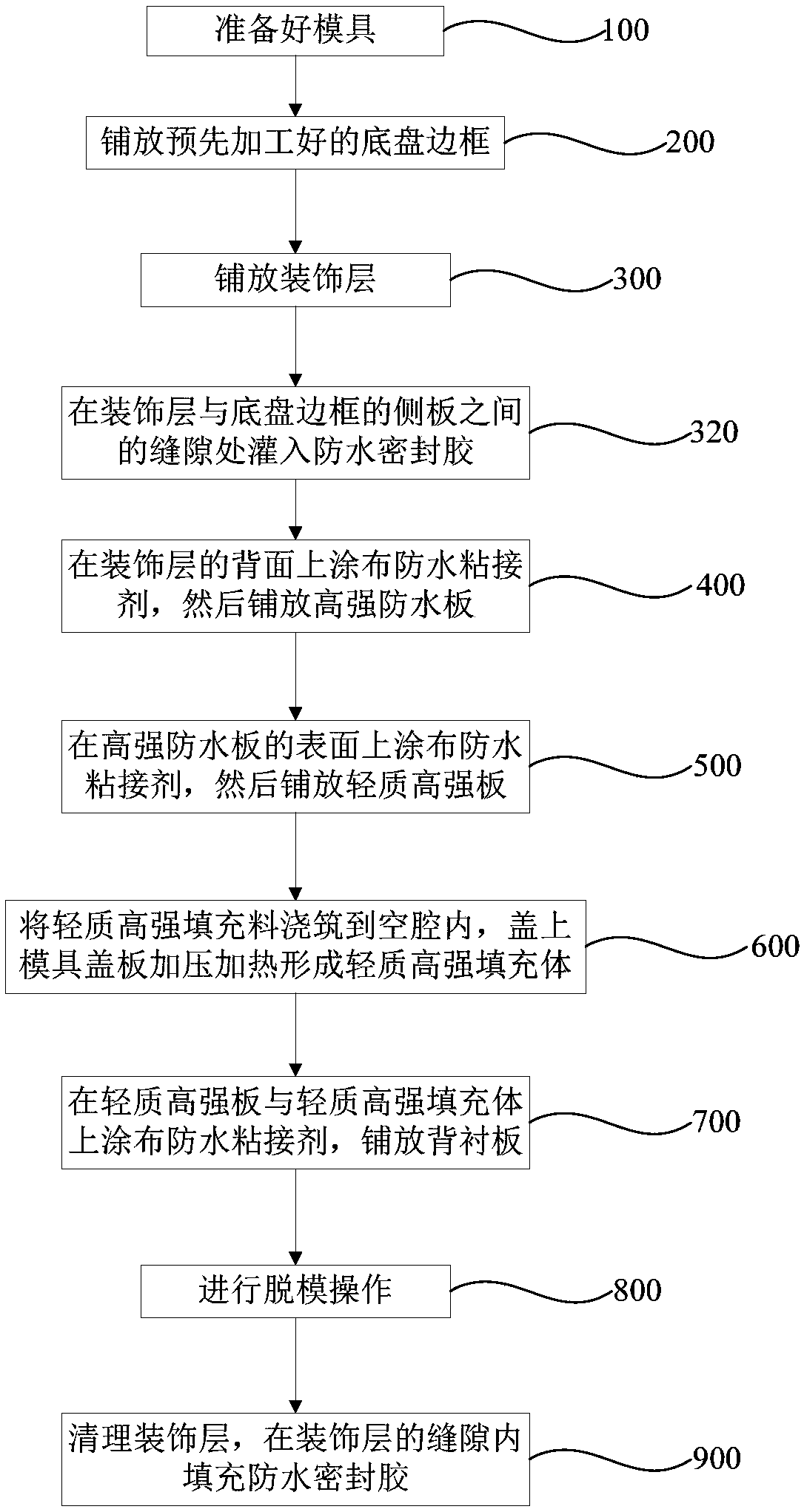

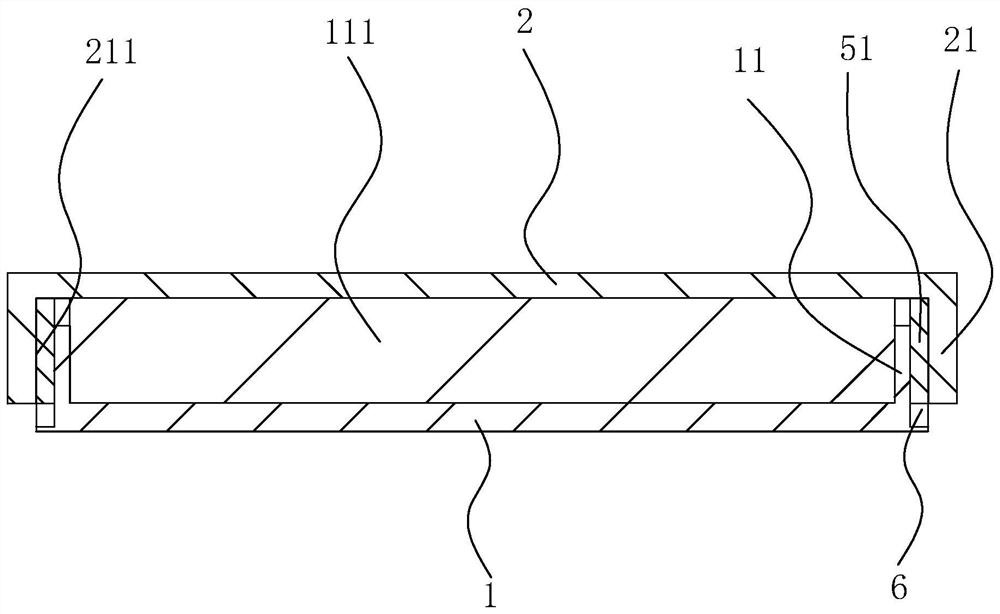

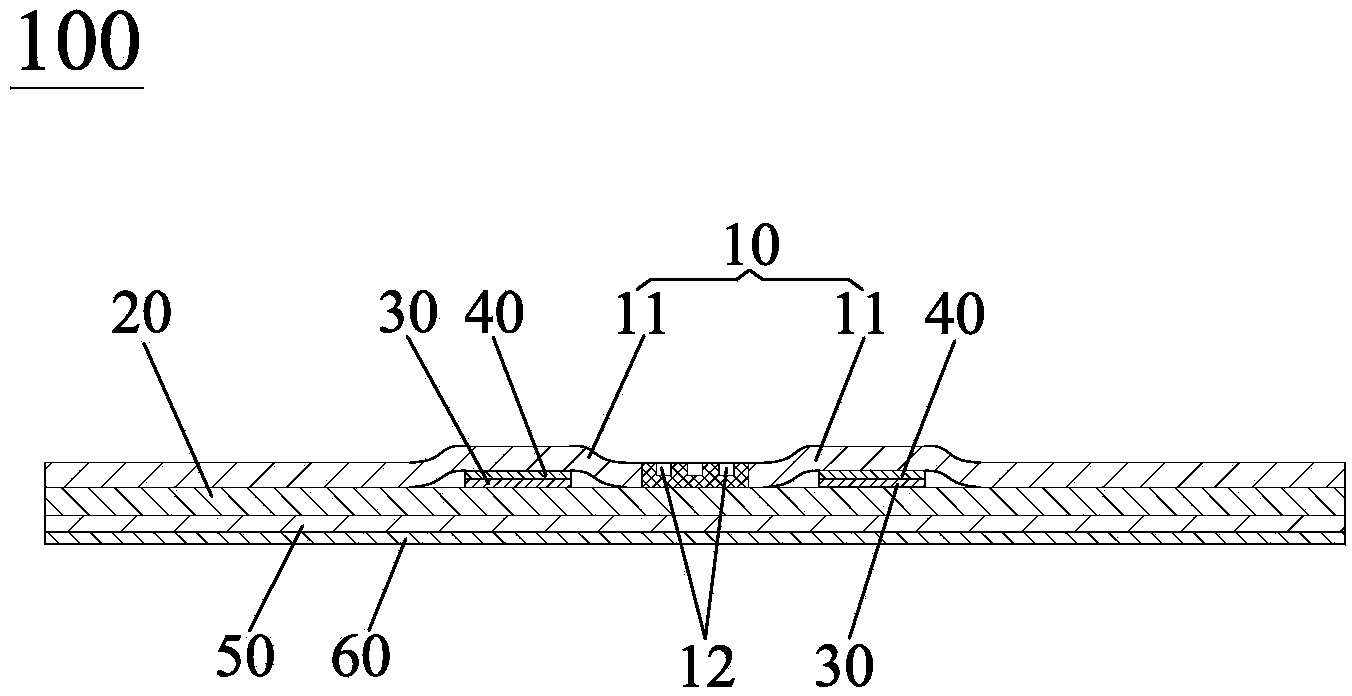

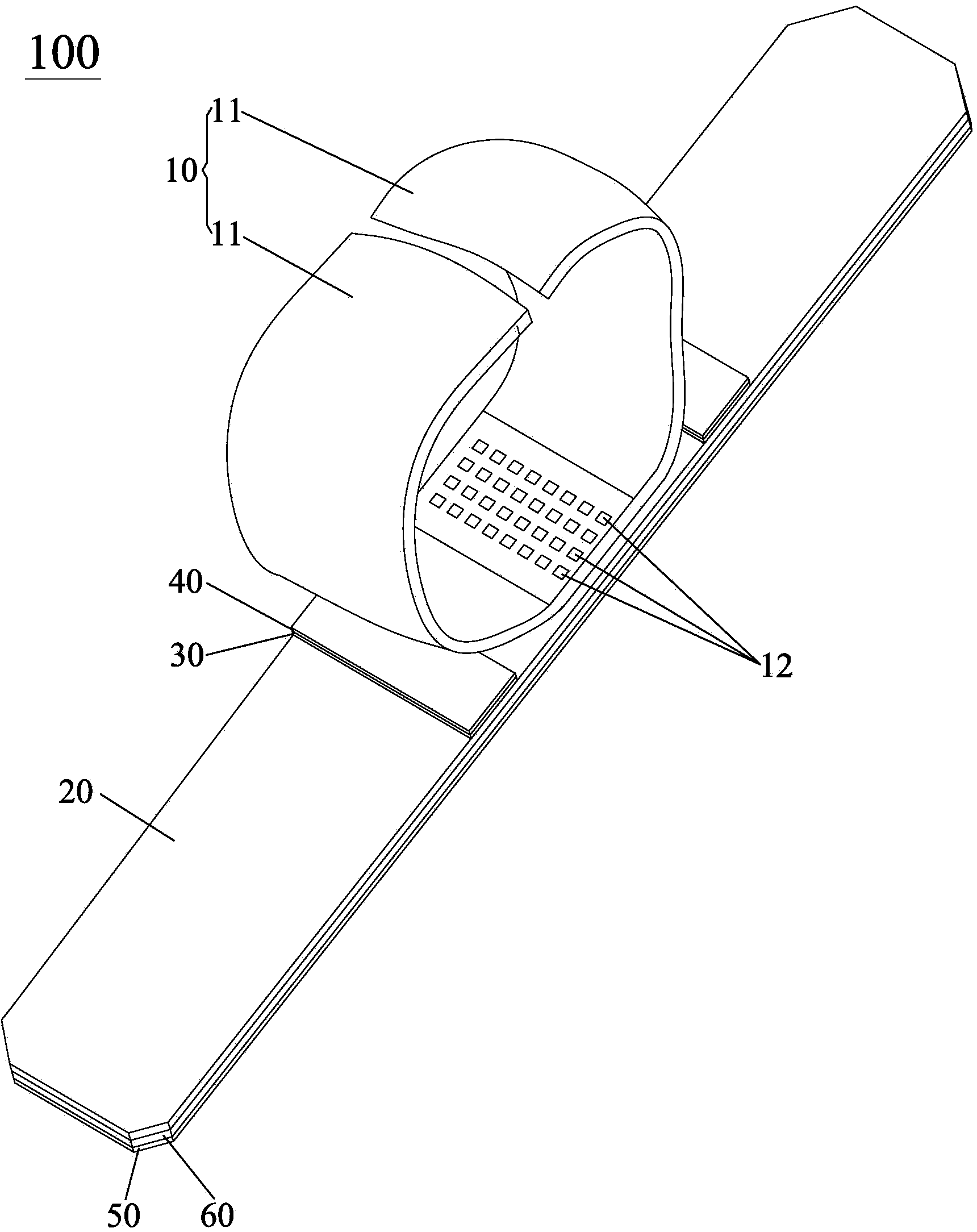

Integral bathroom waterproof chassis and manufacturing method thereof

The invention relates to an integral bathroom waterproof chassis and a manufacturing method thereof. The integral bathroom waterproof chassis comprises a waterproof plate, a support plate and a chassis frame. The waterproof plate is fixedly laid on the support plate. The chassis frame is arranged at the side of the waterproof board and the support board, and the chassis frame is provided with a cavity. The cavity is filled with a filler. The integral bathroom waterproof chassis can be manufactured by fixing the waterproof plate on the support plate and injecting a filling body into the cavityof the chassis frame at the side of the support plate. There is no need to use expensive SMC materials, as SMC molding process on the mold requirements are very high. In addition, the waterproof board, the support board and the chassis frame are assembled together after being prefabricated, the process is simple, pollution-free, the manufacturing process is controllable, and the production efficiency is high.

Owner:GUANGDONG LIANCHENG RESIDENTIAL EQUIP INFORMATION TECH CO LTD +1

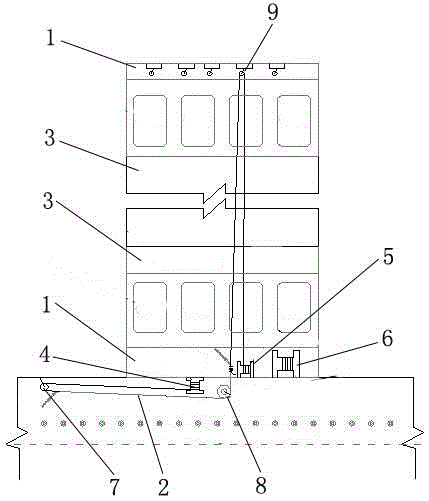

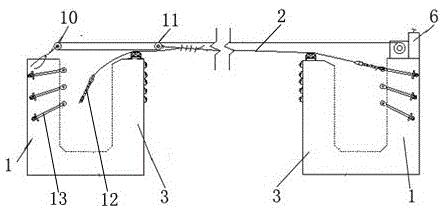

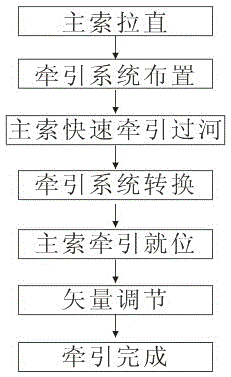

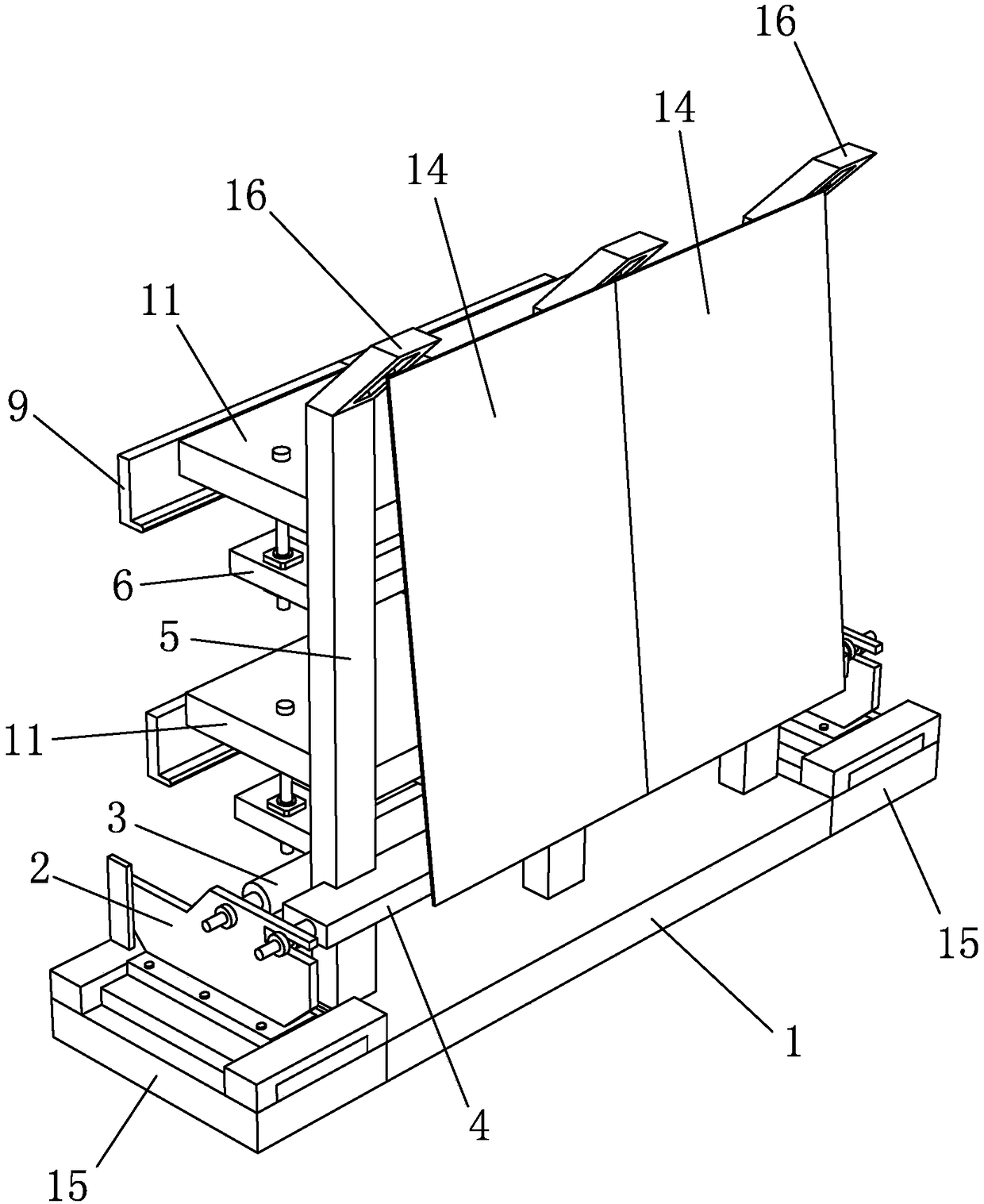

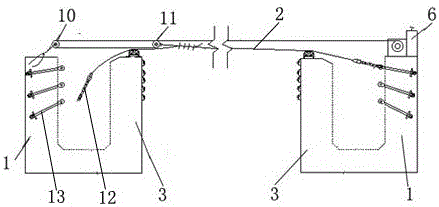

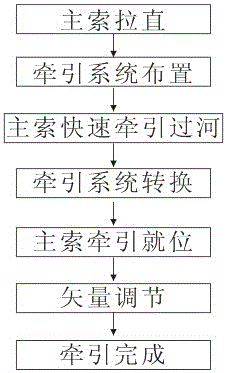

Method for quickly setting up main ropes of suspension bridge

ActiveCN105113414AReduced traction requirementsGood choiceSuspension bridgeBridge structural detailsTerrainTraction system

The invention discloses a method for quickly setting up main ropes of a suspension bridge. The method comprises the steps that one main rope is straightened and looped; a traction system is arranged; the movable end of the main rope is pulled to the opposite bank, and temporary connection is carried out; the traction system is transformed, a fixed pulley block and a movable pulley block are used for continuing to pull the movable end of the main rope to the design position; a fork lug type adjusting lock is manually adjusted, and the vector of the main rope is adjusted to the design requirement; and the rest of main ropes continue to be set up according to the above steps. According to the method, the traction cost of the main ropes of the cableway bridge is greatly reduced, work efficiency is improved, and the method is particularly suitable for traction of main ropes of cableway bridges of various spans, widths and main rope tensions in various precipitous-terrain places with traffic inconvenience.

Owner:NO 7 ENG CO OF CHINA RAILWAY NO 8 ENG GRP CO LTD

Fabricated wood plastic plate

ActiveCN110107050APrevent thermal expansion and contractionAvoid thermal expansion and contractionFlooringMating connectionThermal expansion

The invention belongs to the technical field of wood plastic plates, and particularly relates to a fabricated wood plastic plate. The fabricated wood plastic plate comprises a plate body; an insertinggroove is formed in one end of the plate body, and an inserting block is arranged at the other end of the plate body; hinging seats are arranged at the upper end and the lower end of the inserting groove, and arc-shaped inserting plates are hinged to the hinging seats through hinging rods; arc-shaped sliding grooves are formed in the upper side face and the lower side face of the inserting block,and arc-shaped fixed grooves are formed in the two side faces of the arc-shaped sliding grooves; air guiding cavities are formed in the arc-shaped inserting plates, elastic expansion films are arranged on the two side faces of the arc-shaped inserting plates, and the air guiding cavities are connected with the elastic expansion films through air guiding grooves; the elastic expansion films and the arc-shaped fixed grooves are connected in a matched mode; and an elastic airbag is arranged in the inserting groove, thus the expanded elastic expansion films can be clamped into the arc-shaped fixed grooves, then the inserting block and the inserting groove can be quickly and fixedly connected, and the situation that the wood plastic plate is prone to expansion and contraction, then when wood plastic plates need to be mutually connected, reserved gaps are excessively large, and consequently stable connection between the wood plastic plates is affected is prevented.

Owner:江苏昊星新材料有限公司

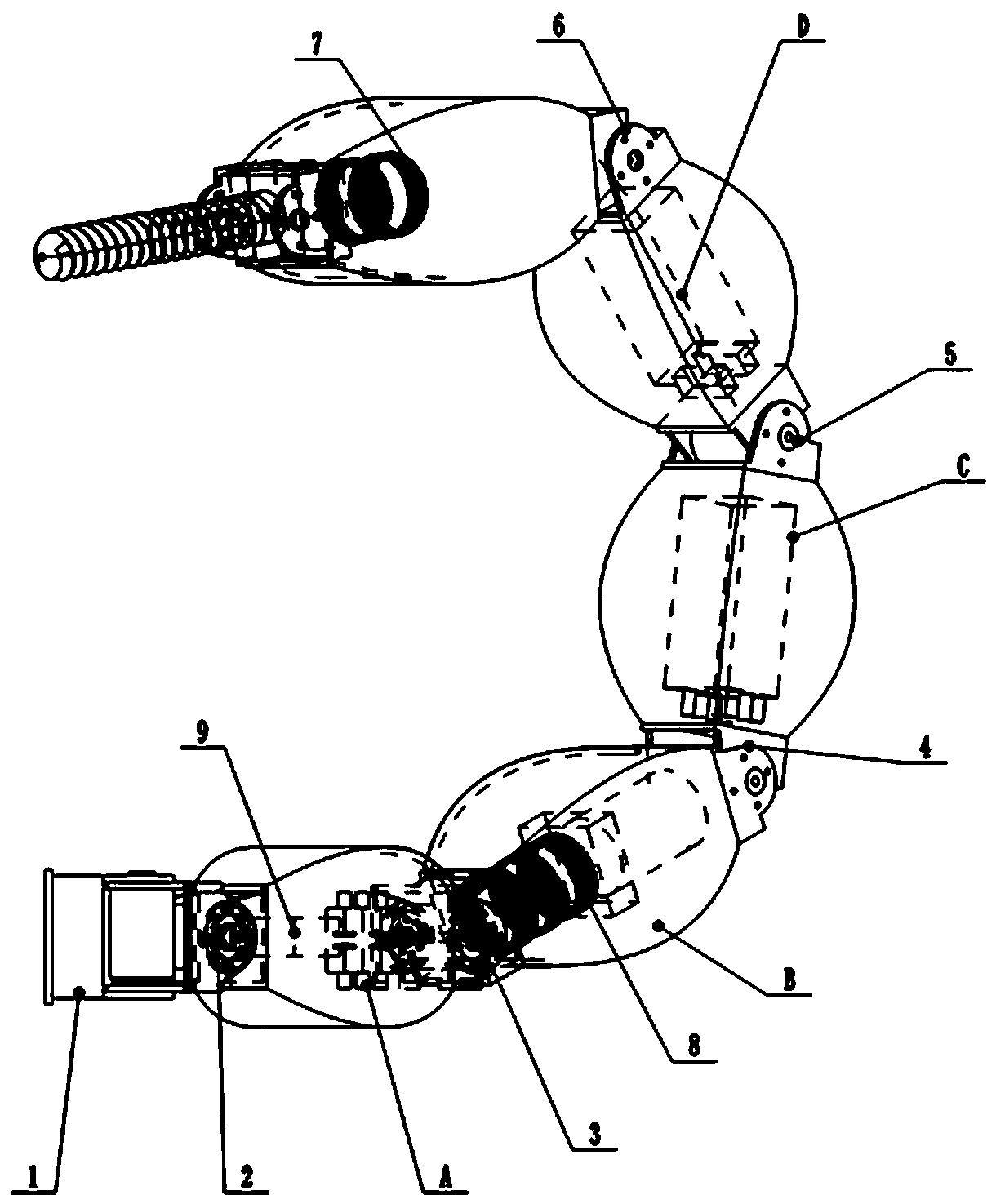

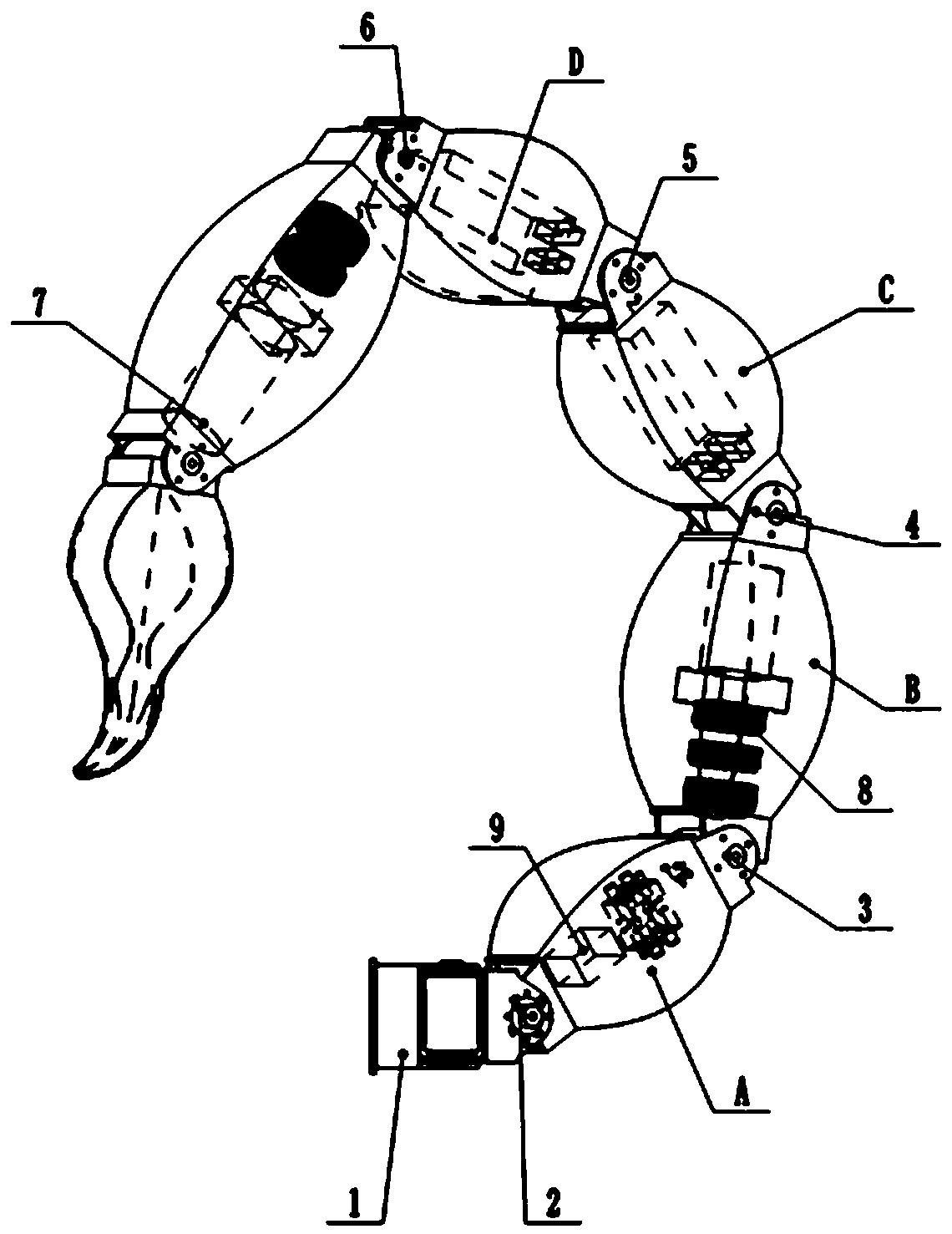

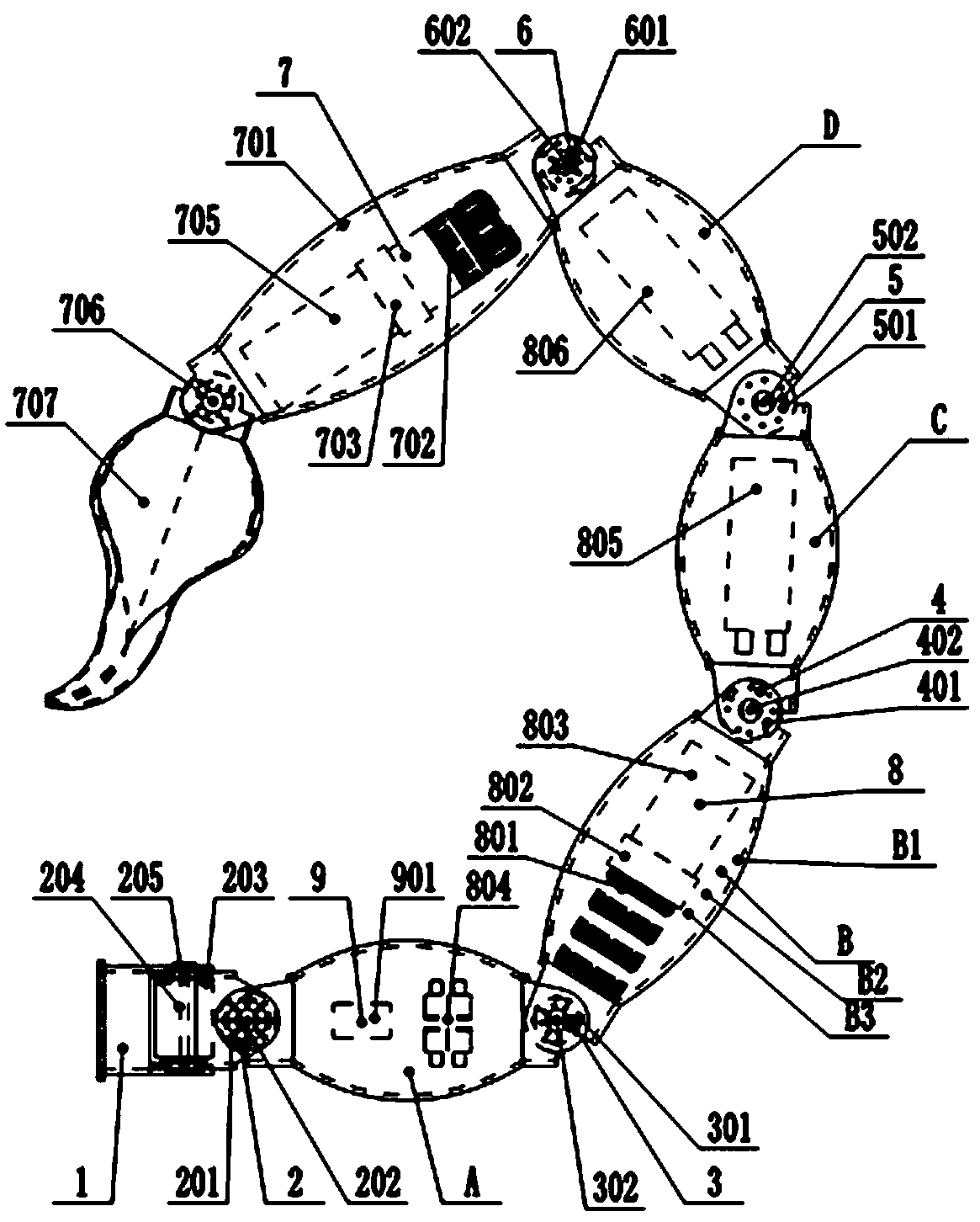

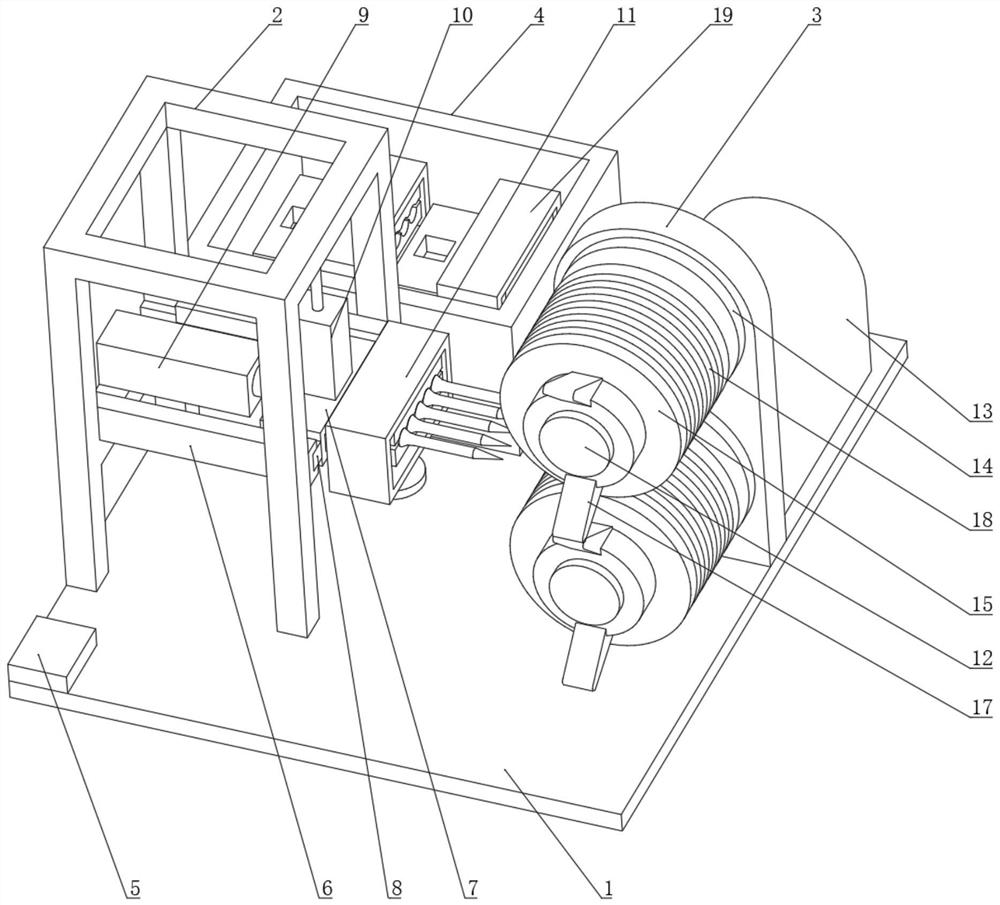

Multi-joint bionic diploe with autonomous hydraulic distribution power

PendingCN108705524AQuick fix connectionQuick dismantlingProgramme-controlled manipulatorBatteries circuit arrangementsFailure rateElectricity

A multi-joint bionic diploe with autonomous hydraulic distribution power comprises a connecting frame and tail joints. A three-dimensional joint, a two-dimensional joint, a caudal spine device, a hydraulic power system and an electronic control device are further arranged, the number of the tail joints is larger than or equal to 4, and the three-dimensional joint is fixed to the connecting frame and connected with the tail joints. The tail joints are connected end to end by the two-dimensional joint, the caudal spine device is connected with that tail joint through the two-dimensional joint,the hydraulic power system is fixed in the cavity of the tail joint, and is respectively connected with the hydraulic interfaces of the three-dimensional joint, the two-dimensional joint and the caudal spine device through hydraulic pipelines. The electric control device is fixed in the cavity of the connecting frame or / and the tail joint or / and the caudal spine device, and the electric controldevice is respectively electrically connected with the hydraulic power system, the three-dimensional joint, the two-dimensional joint and the caudal spine. The invention has a simple structure and isconvenient to install and disassemble. The advantage of low failure rate, high reliability and high bearing capacity make it convenient for bionic mechanical scorpion to be used in earthquake rescue,security protection, military reconnaissance and field exploration.

Owner:长沙紫宸科技开发有限公司

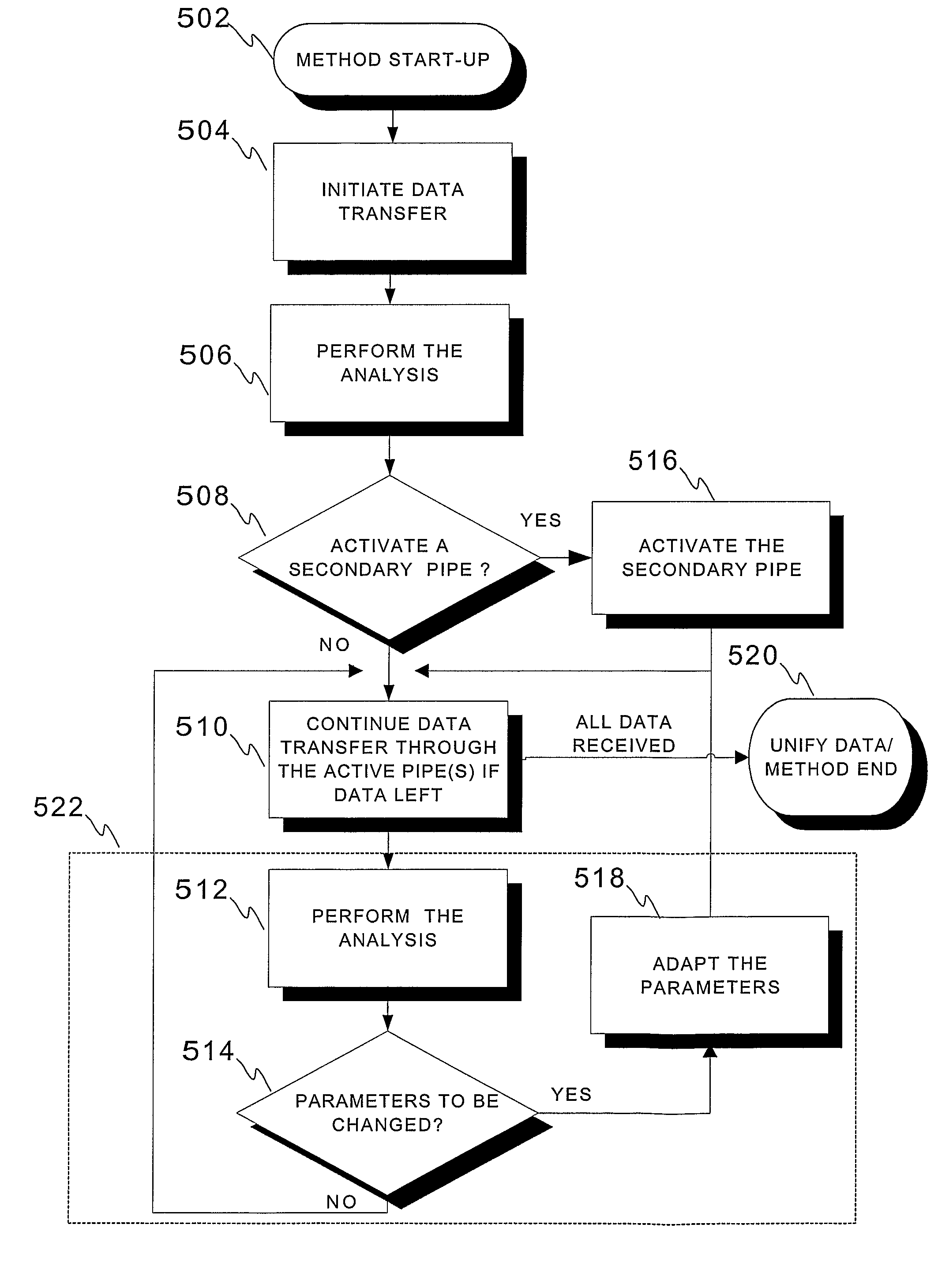

Method, a device and a system for transferring data

InactiveUS7796531B2Reduce deficiencyImprove experienceError preventionFrequency-division multiplex detailsData sourceComputer science

A method, a device and a system for transferring data from a data source (212) over both a wireless communications (210) and a fixed communications (208) network to a destination device (204) such that at least one portion of a data aggregate is transmitted through the wireless communications network (210) via a wireless communications device (202) and at least one another portion is transmitted through the fixed communications network (208). The destination device (204) may reconstruct the data aggregate by joining the received data portions together.

Owner:NOKIA CORP

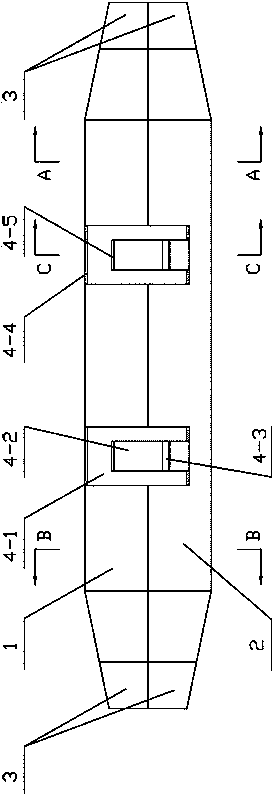

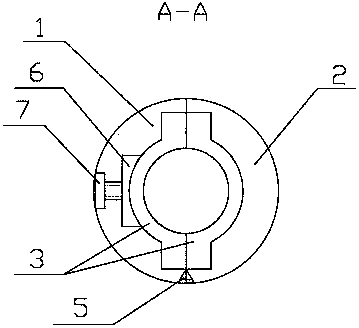

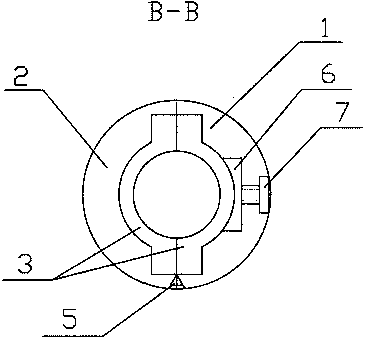

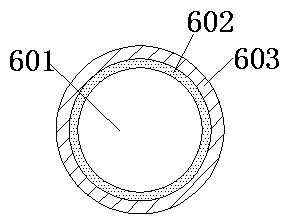

Counterweight device for towing-type linear array and towing-type linear array

ActiveCN104047994ARealize fixed depthImprove detection performanceWave based measurement systemsCounterweightsLocking mechanismEngineering

The invention provides a counterweight device for a towing-type linear array and the towing-type linear array. The counterweight device for the towing-type linear array comprises a first semi-cylinder counterweight block, a second semi-cylinder counterweight block, a buckle-type locking mechanism and a first hinge, wherein the section of each counterweight block is of a semi-circular ring shape; one contact surface of the first semi-cylinder counterweight block is connected with one contact surface of the second semi-cylinder counterweight block through the first hinge; when the opening angle of the first semi-cylinder counterweight block and the second semi-cylinder counterweight block is zero, the two counterweight blocks are matched with each other to form a hollow cylinder; when the first semi-cylinder counterweight block and the second semi-cylinder counterweight block are opened at a certain angle, a towing cable is placed in a hollow part of the cylinder; the buckle-type locking mechanism is used for clamping the first semi-cylinder counterweight block and the second semi-cylinder counterweight block on the towing cable placed in the hollow part when the opening angle is zero; a first conical flow guide section is further arranged at the end part of the cylinder formed by the first semi-cylinder counterweight block and the second semi-cylinder counterweight block.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

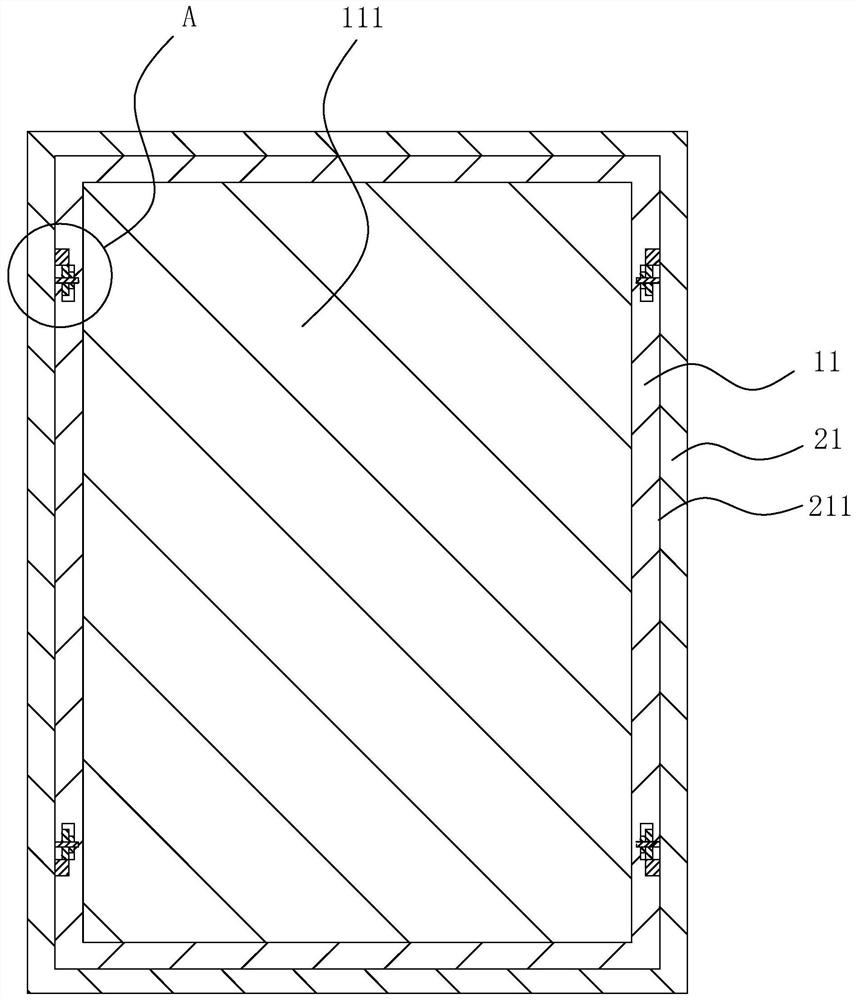

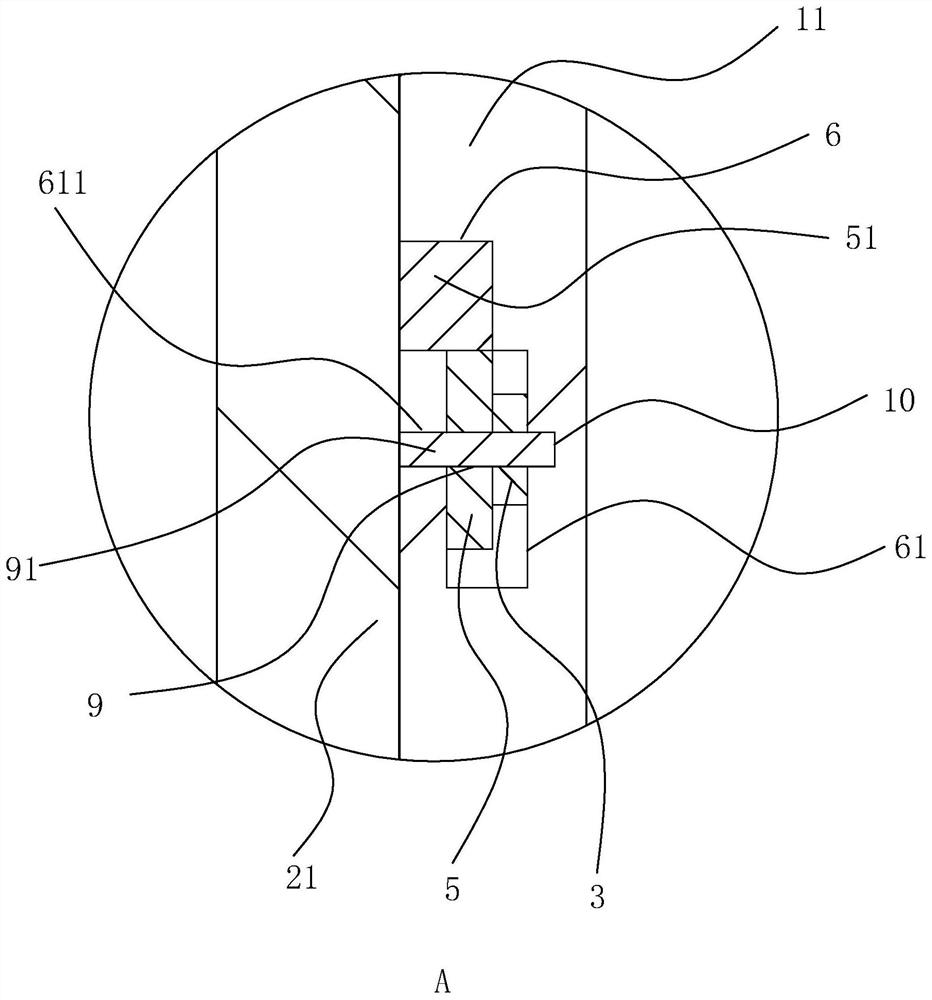

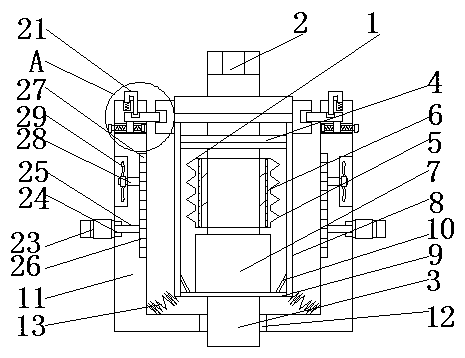

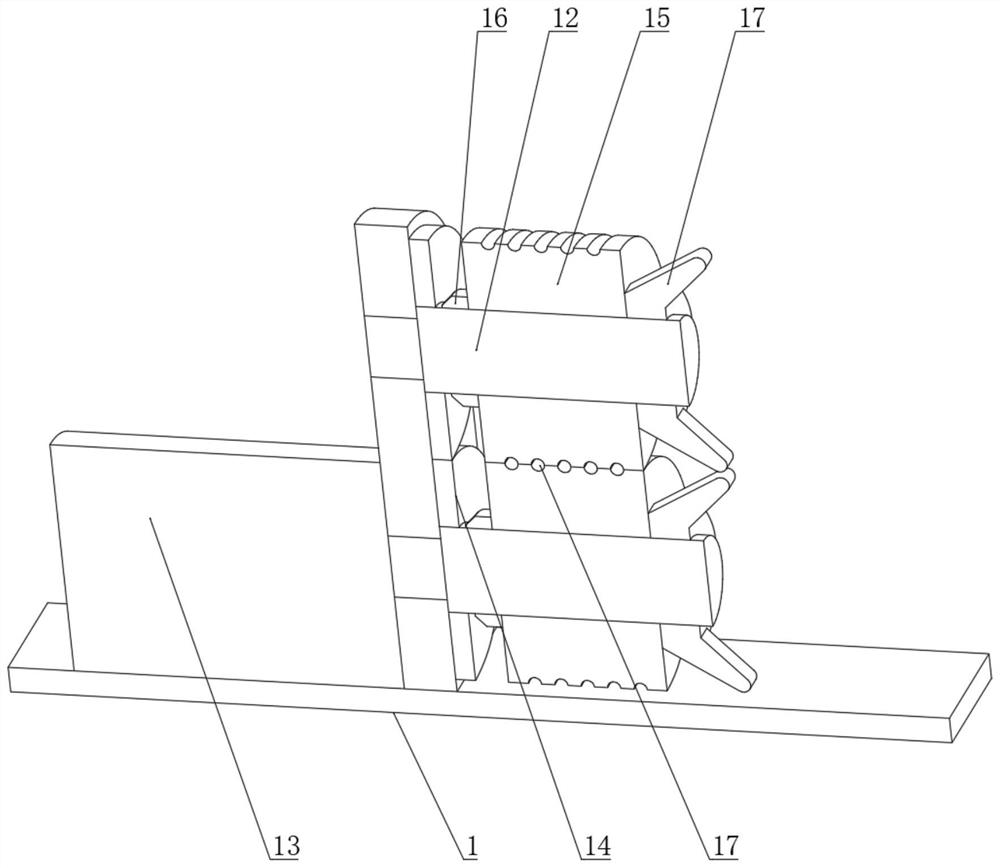

Fireproof door quick mounting structure

ActiveCN112081510AMeet the installationQuick fix connectionFireproof doorsDoor leavesRatchetGear wheel

The invention relates to a fireproof door quick mounting structure. The technical scheme of the fireproof door quick mounting structure is that fixing devices are arranged on a first mounting plate and a second mounting plate; each fixing device comprises a ratchet wheel, a pawl, a steel ring, a gear and a rack; a sliding groove allowing the rack to be inserted is formed in the end part of the first mounting plate; a locking groove is formed in the inner side wall of the sliding groove; the ratchet wheel is rotationally arranged in the locking groove; the pawl is hinged into the locking groove; the end part of the pawl is matched with the ratchet wheel; one end of the steel ring is fixed to the outer side wall of the pawl; the other end of the steel ring abuts against the inner wall of thelocking groove; the gear is fixedly arranged on the outer side wall of the ratchet wheel; the ratchet wheel and the gear are coaxially arranged; and the rack is matched with the gear. The fireproof door quick mounting structure has the effects that the fireproof door can be conveniently and rapidly mounted, and the requirements of fireproof materials with different thicknesses are met.

Owner:上海逸盾门业有限公司

Novel vacuum switch tube convenient to connect

InactiveCN110911217AFirmly connectedQuick fix connectionContact vibration/shock dampingHigh-tension/heavy-dress switchesGear wheelScrew thread

The invention discloses a novel vacuum switch tube convenient to connect, and the novel vacuum switch tube convenient to connect comprises an equipment main body, a conductive rod, a movable contact,a fixed contact, a guide sleeve, a cover plate, a screw rod, a threaded sleeve, a first groove, a third spring, a first gear, a second gear and a second rotating rod, and the upper end of the equipment main body is provided with an exhaust pipe. The screw rod, a movable block and an adjusting rod are arranged in the novel vacuum switch tube convenient to connect; the adjusting handle is manually rotated, the screw rod fixedly connected with the adjusting handle is driven to rotate; the screw rod is in threaded connection with the threaded sleeve; the threaded sleeve moves in the horizontal direction and can drive the movable block to move, the movable block is clamped with the first groove, the adjusting rod is pulled, the adjusting rod is pulled to enable the third spring to be stretchedand deformed, the adjusting rod is loosened, the adjusting rod can be clamped in the second groove under the reset effect of the third spring, and the vacuum switch tube can be rapidly connected and fixed conveniently.

Owner:昕致潮贸易(深圳)有限公司

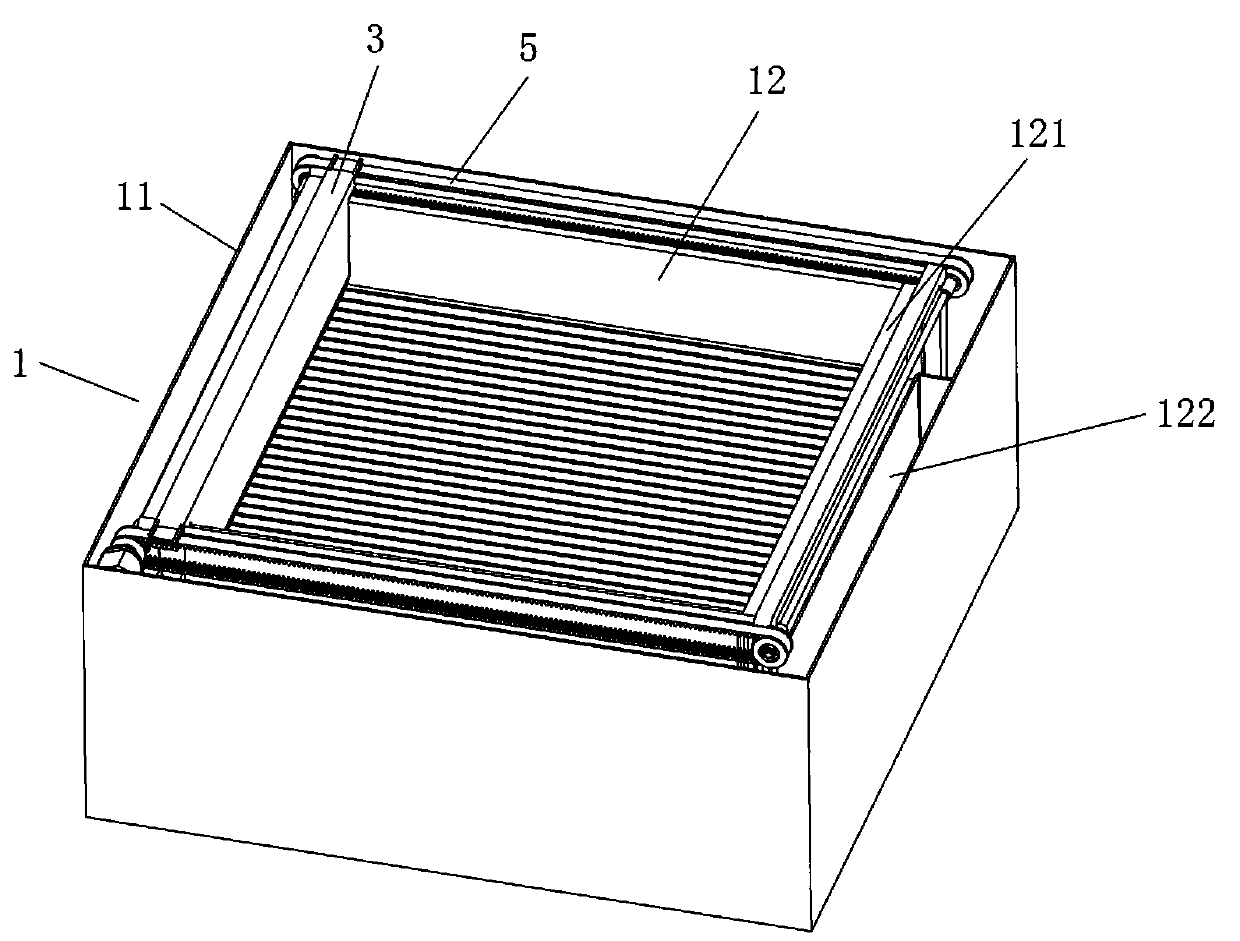

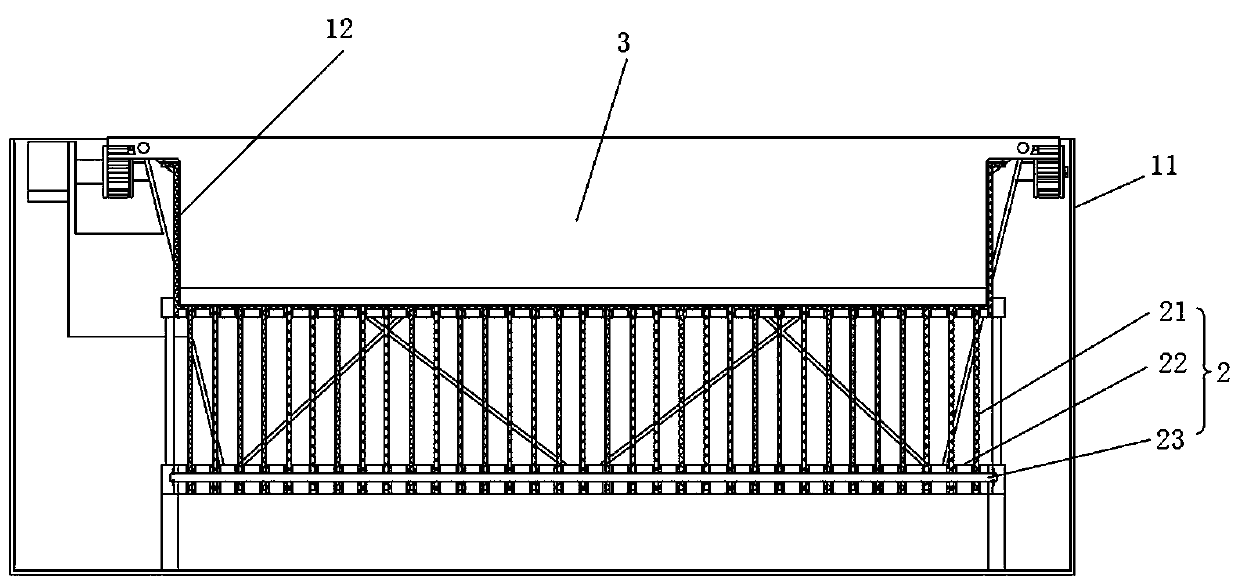

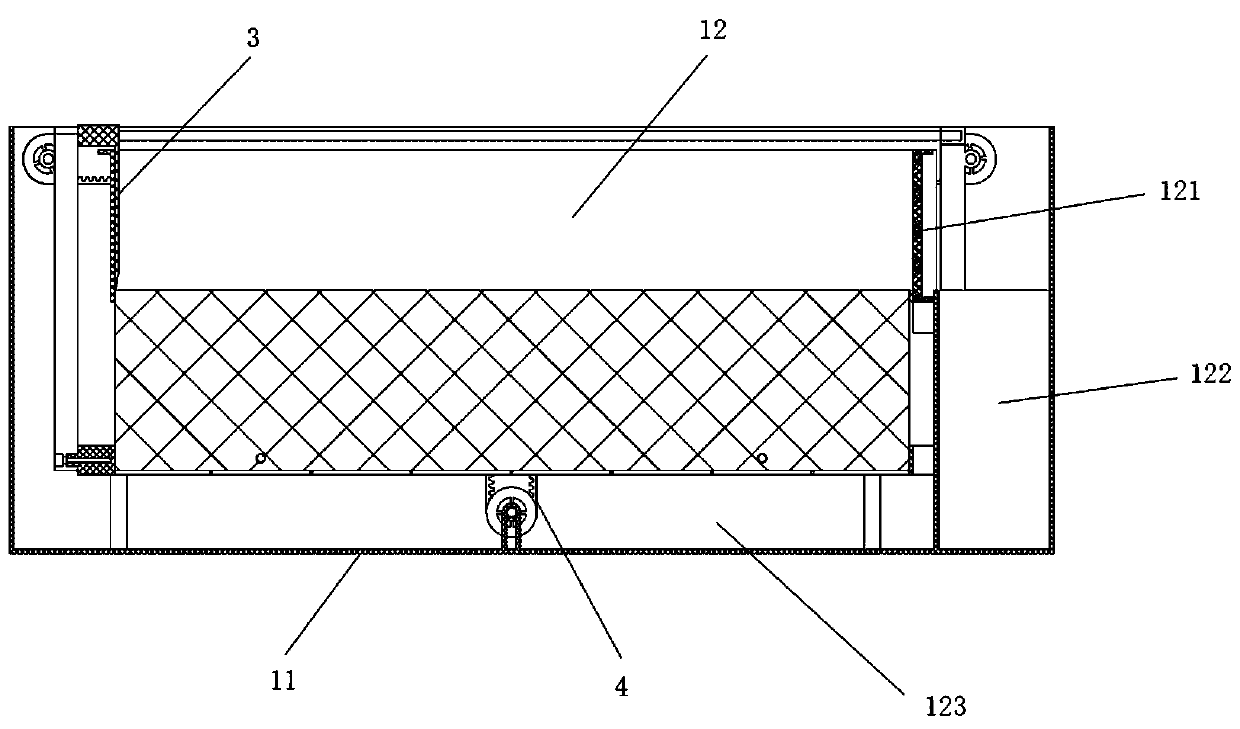

Automatic cat litter basin

PendingCN111387066ASolve the problem of large-scale pollutionReduce movementAnimal housingLitterEnvironmental engineering

The invention is suitable for the technical field of pet products, and discloses an automatic cat litter basin. The automatic cat litter basin comprises a basin body and an automatic cleaning mechanism integrally installed in the basin body, wherein the automatic cleaning device comprises a grid plate component which is installed in the basin body and can vertically lift and lower; the initial state of the gird plate component is used for combining with the bottom of the basin body to contain car litters; when the gird plate component is lifted, the cat litters and excreta are separated; and when the grid plate component is lifted, cat feces and cat litters which cake after the cat litters are polluted are lifted, and clean cat litters are left in a gap of the gird plate component. The automatic cat litter basin has a simple structure and is conveniently separated, and the inner wall of the basin body is not touched.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

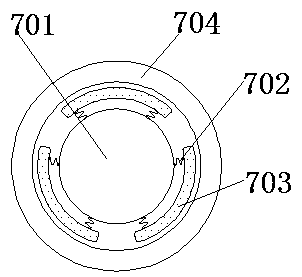

Micro rotary locking device

ActiveCN112615205AQuick sealQuick fix connectionCouplings bases/casesElectrical connectionEngineering

The invention relates to a micro rotary locking device. The device comprises a locking fixed end and a rotary movable end which are rotationally buckled to achieve mutual locking, wherein a rotary matching groove is formed in the locking fixed end, the rotary matching groove comprises a starting section and a locking section which communicate with each other, and the front end of the locking section is provided with a stopping part extending towards the interior of the locking section; an elastic sealing unit is arranged in a mounting groove formed in the locking fixing end; the rotary movable end is provided with a rotary fit key in rotary fit with the rotary fit groove and a protruding part corresponding to the installation groove, and the rotary fit key is provided with a locking part in stop fit with the stop part in the front-back direction. In the locking state, the elastic sealing unit provides elastic force for the protruding part so that the locking part can abut against the blocking part, the locking fixed end and the rotating movable end can be locked in the front-back direction, rapid assembling and disassembling of the locking fixed end and the rotating movable end can be achieved, operation is convenient, and practicability is high. Rapid sealing and fixed connection of various parts can be realized, and related functions of the electrical connection assembly can be further realized.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Construction method of stable gabion stone cage retaining wall

ActiveCN109056784APlay a supporting roleDetermination of inclinationArtificial islandsBreakwatersSoil horizonRetaining wall

The invention discloses a construction method of a stable gabion stone cage retaining wall. The method comprises the following steps of (a) foundation pit excavation, (b) manufacturing of gabion stonecages, (c) gabion stone cage assembling at a foundation pit (d) mounting of a support rod, (e) mounting of a sliding rod at the bottom of a workbench, (f) mounting of the workbench, (g) hanging of asteel wire gauze, (h) stacking of the gabion stone cages from bottom to top layer by layer, (i) fixing of the gabion stone cages stacked up and down, (j) earthwork backfilling, (k) greening and (l) monitoring and measurement. Protective surfaces of the gabion stone cages stacked up and down can be located on the same inclined surface, every two gabion stone cages stacked up and down can be rapidlyand fixedly connected, a flexible integral protection surface is formed, thus, the overall structure of the retaining wall is firm, the stability is good, the retaining wall can adapt to various soillayer properties, can be combined well with soil layers and can adapt well to ground deformation, the overall structure is not weakened, fracture and damage are not prone to occurring, the water permeability is high, and the erosion resistibility is improved.

Owner:浙江广辉建设有限公司

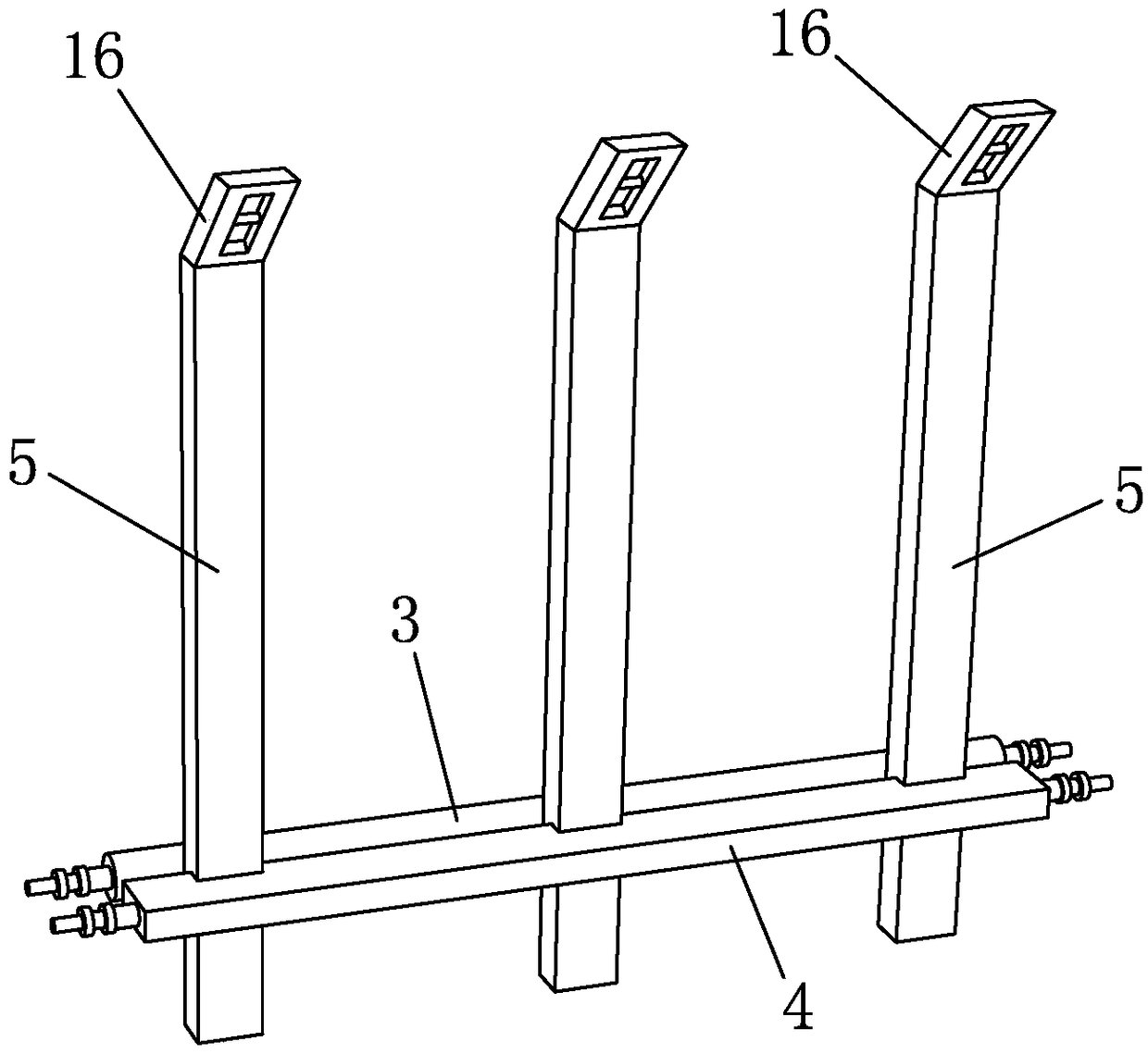

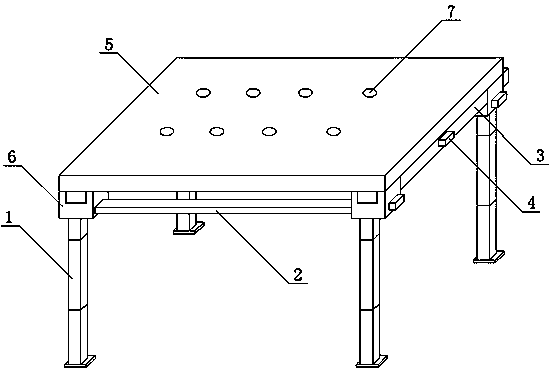

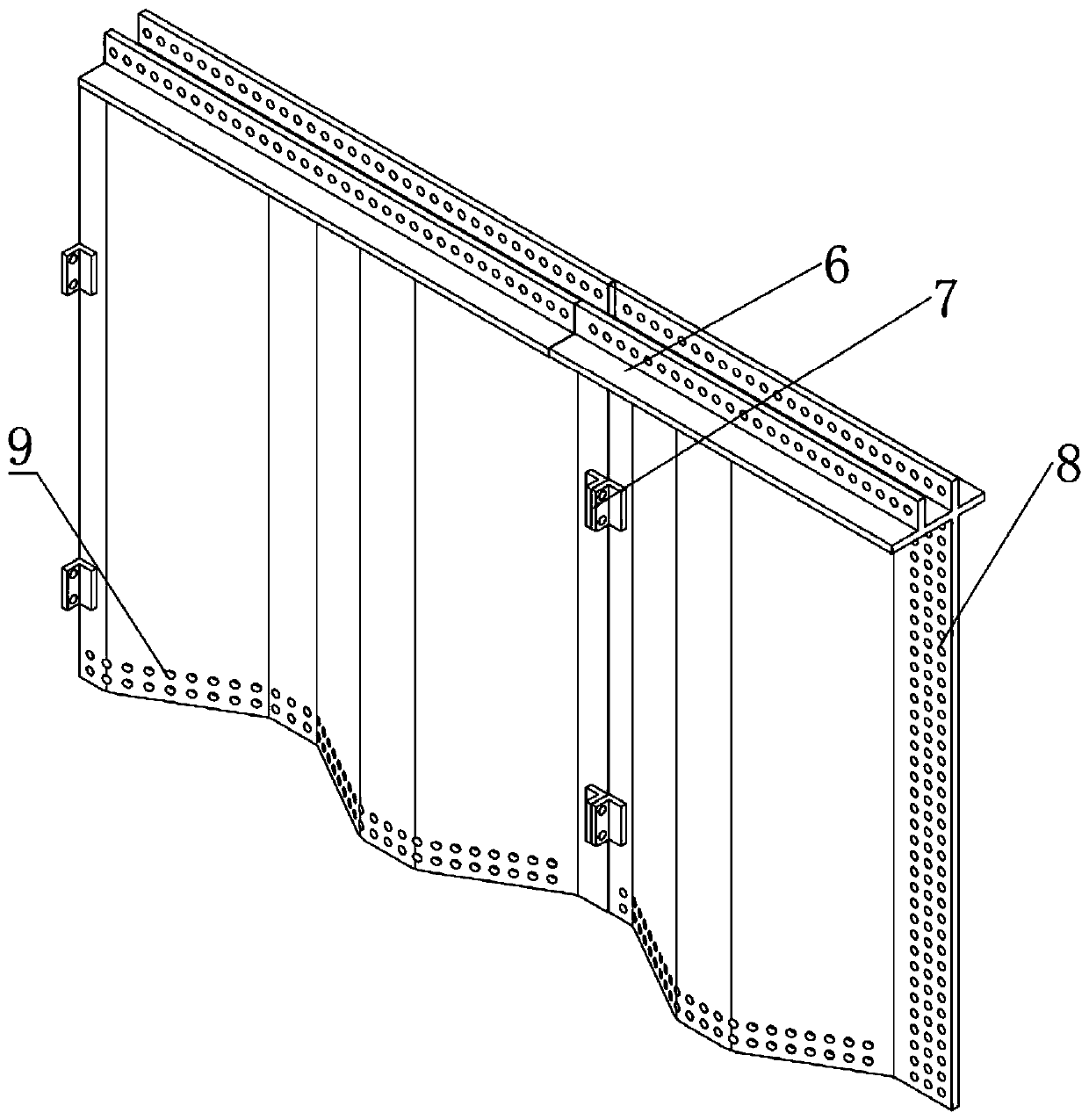

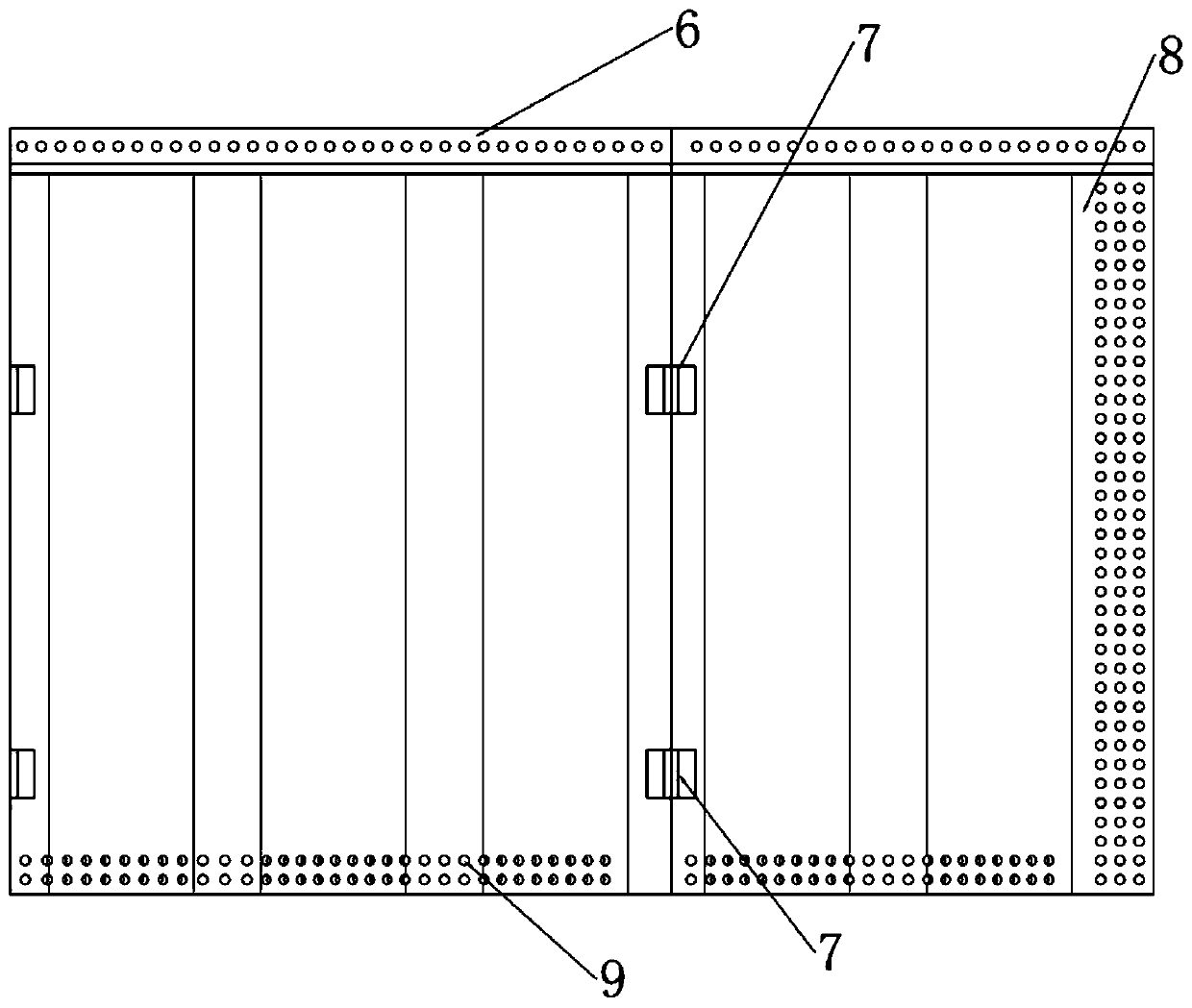

Detachable steel-structure platform

InactiveCN103590592AEasy to install and removeReasonable structureBuilding scaffoldsMechanical engineeringClassical mechanics

A detachable steel-structure platform comprises stand columns (1). Fixing and connecting pieces (6) are fixedly arranged on the upper end portions of the stand columns (1), through holes are formed in the four faces of each fixing and connecting piece (6) respectively, a transverse beam (2) and a longitudinal beam (3) are vertically fixed to the same fixing and connecting piece (6), the two transverse beams (2) and the two longitudinal beams (3) form a rectangular frame, a platform (5) is arranged at the upper ends of the fixing and connecting pieces (6), and the upper ends of the fixing and connecting pieces (6) protrude and are inserted into grooves formed in the bottom of the platform (5). The two transverse beams and the two longitudinal beams are adopted to form the rectangular frame, the stand columns, the transverse beams and the longitudinal beams can be effectively connected and fixed together through the fixing and connecting pieces, all the components can be disassembled and assembled, fast connecting and fixing can be achieved through the fixing and connecting pieces (6), and the platform is convenient to dismount after construction and has good application prospects in steel structure construction and other mounting fields.

Owner:HUBEI ABSOLUTE SINCERITY STEEL STRUCTURE

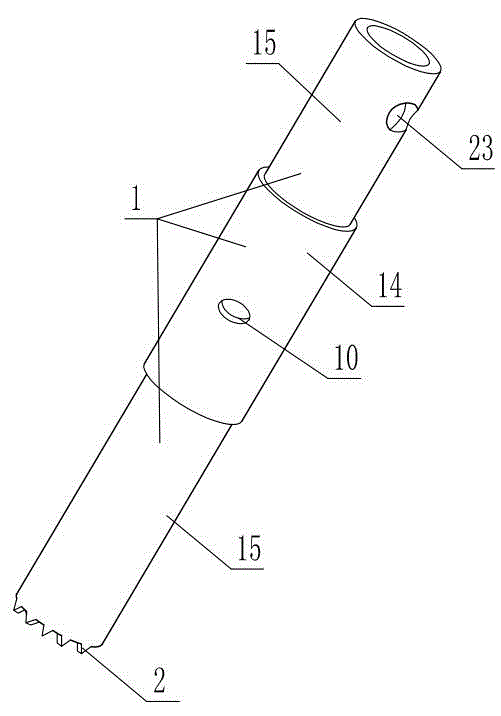

Broken nail extractor

The invention discloses a broken nail extractor. The broken nail extractor comprises a round tube with a milling opening and a locking opening, wherein milling teeth extending downwards are annularly arranged on the milling opening of the round tube, a polygonal clamp piece is mounted at the upper end of the round tube through a connecting mechanism, an inner barrel with the opening arranged downwards is inserted into the round tube, clamping pieces extending downwards and supported to be open towards the outside are annularly arranged at the opening of the inner barrel at intervals, clamping teeth extending axially are arranged on the inner walls of the clamping pieces, all the lower ends of the clamping pieces are positioned on the axial extension locus of the round tube, a polygonal column is fixedly arranged at the upper end of the inner barrel, external threads are arranged in the middle of the inner barrel, and internal threads in screwing match with the external threads are arranged in the middle of the inner wall of the round tube. The broken nail extractor has the effects that the outer ends of broken nails can be fixed and connected rapidly, in addition, the broken nails can be screwed out smoothly, the operation is convenient, one person can complete the operation, moreover, the wound surface is small, and thus the rapid rehabilitation after the operation can be benefited.

Owner:董高正

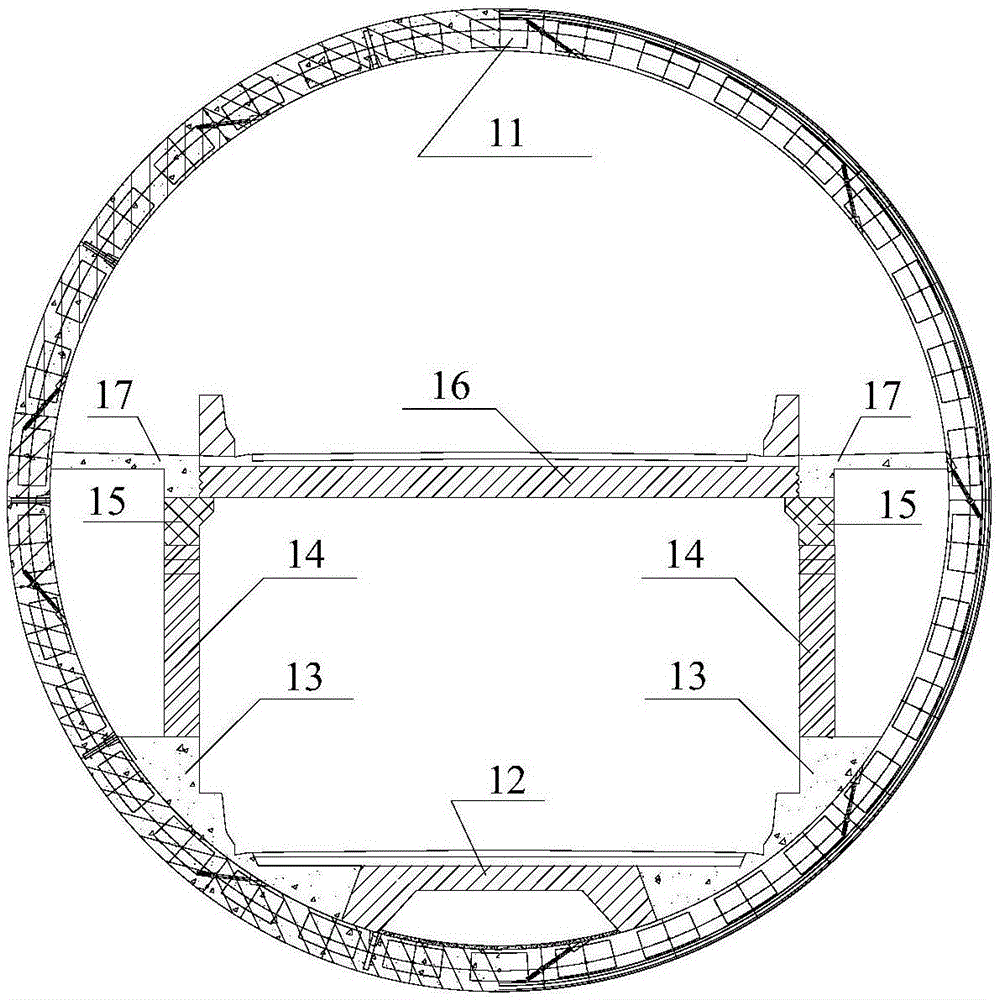

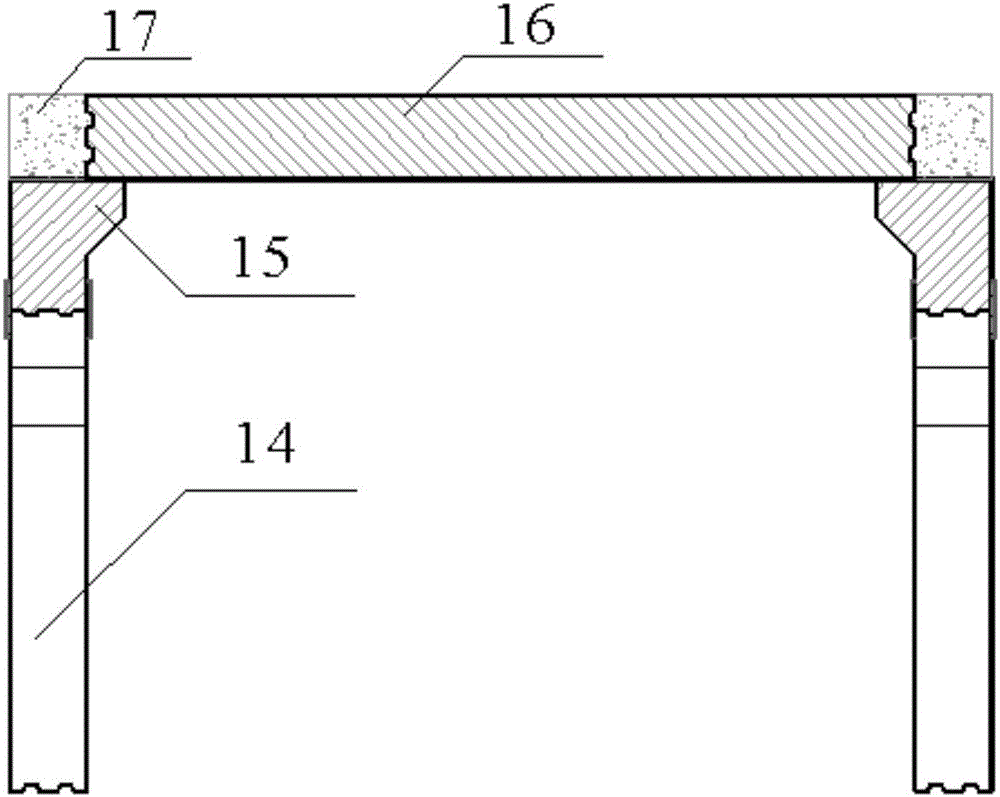

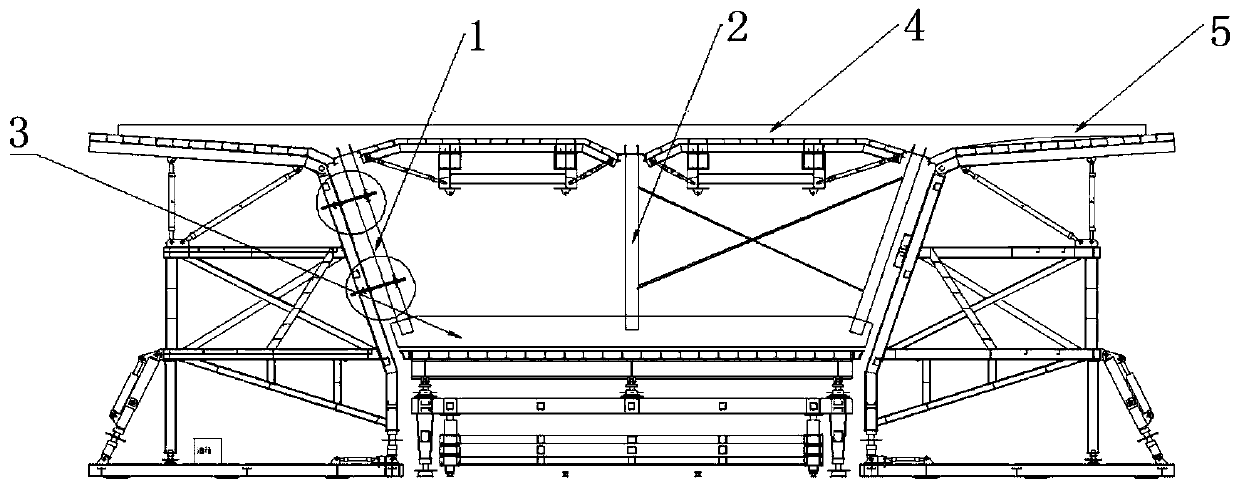

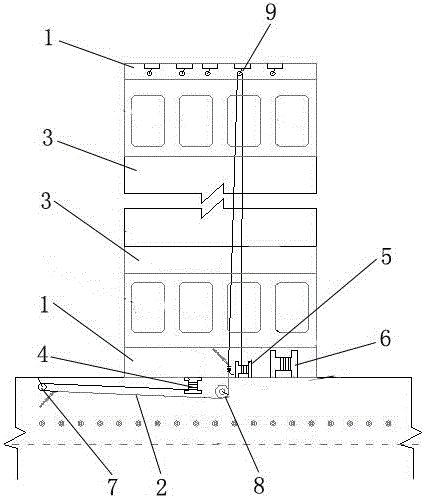

Round-tunnel double-layer lane frame structure system and full-prefabricated construction method thereof

PendingCN106400629AImprove efficiency and qualityReduce construction wasteRoadwaysEngineeringEnergy consumption

The invention discloses a round-tunnel double-layer lane frame structure system and a full-prefabricated construction method thereof. The round-tunnel double-layer lane frame structure system comprises a round tunnel, a prefabricated lower-layer lane component, bases, prefabricated bracket stand columns, prefabricated bracket longitudinal beams and a prefabricated upper-layer lane plate. The full-prefabricated construction method comprises the steps that the round tunnel is formed; the prefabricated lower-layer lane component is fixedly arranged at the bottom of the round tunnel, so that a lower-layer lane frame structure system body is formed; the bases of an upper-layer lane frame structure system body are poured; and the prefabricated bracket stand columns, the prefabricated bracket longitudinal beams and the prefabricated upper-layer lane plate are assembled on the bases in sequence, and the upper-layer lane frame structure system body is formed through splicing. The round-tunnel double-layer lane frame structure system and the full-prefabricated construction method thereof have the advantages that the construction efficiency and construction quality can be improved, construction waste is effectively reduced, energy consumption is reduced, environmental pollution is reduced, the structure stability is high, the anti-seismic property is good, and the durability is good.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

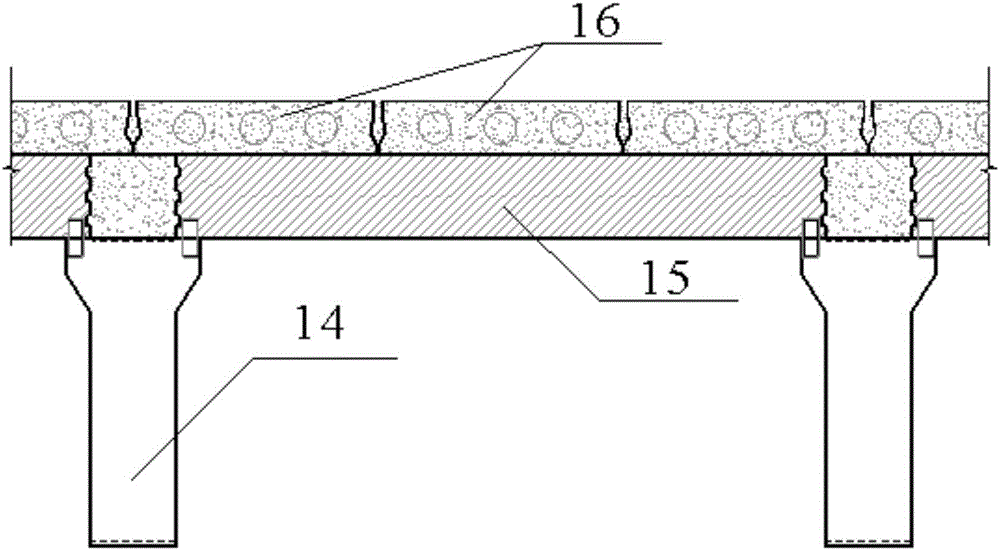

Steel-concrete bridge body and assembling construction process thereof

InactiveCN110700077AGuaranteed reliabilityGuaranteed assembly effectBridge structural detailsBridge erection/assemblyArchitectural engineeringCantilever

The invention discloses a steel-concrete bridge body and an assembling construction process thereof. The beam body is a composite beam formed by longitudinally connecting a plurality of prefabricatedsegmental box girders; each segmental box girder comprises a concrete top plate, a concrete bottom plate, a vertically-arranged middle web plate and a pair of side web plates. The middle web plates and the side web plates are corrugated steel web plates; temporary matching pieces are fixed to the side edges of the corrugated steel web plates. After the temporary matching pieces corresponding to the adjacent corrugated steel web plates are mutually connected, the side edges of the corresponding corrugated steel web plates are mutually matched and attached; the side web plates incline by a certain angle so as to form an inverted trapezoidal structure with the concrete top plates and the concrete bottom plates, and flange cantilevers horizontally extending out of the inverted trapezoidal structure are arranged on the two transverse sides of the concrete top plates. Accurate positioning between the box girders can be achieved only through connection between the temporary matching pieces, then the assembling effect between the box girders is guaranteed, the positioning efficiency is greatly improved, and meanwhile the positioning reliability can be guaranteed.

Owner:CCCC SHEC FOURTH ENG

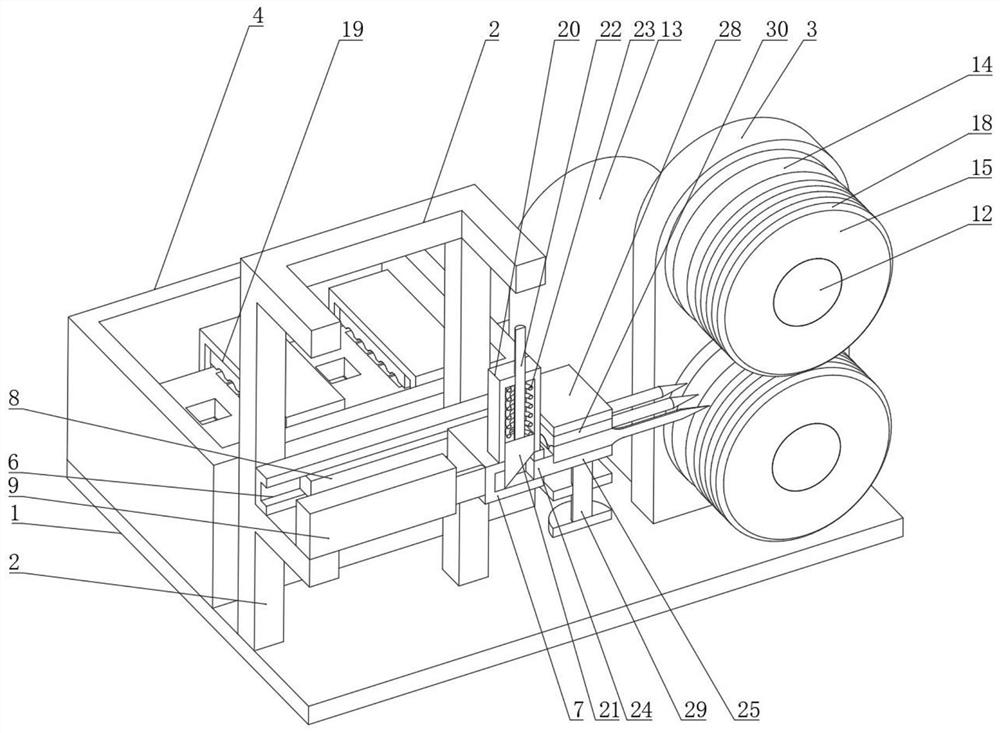

Grinding device for sewing machine needle production

ActiveCN112706034AIncrease feeding speedEasy to install and fixEdge grinding machinesGrinding wheel securing apparatusEngineeringSewing machine

The invention discloses a grinding device for sewing machine needle production. The grinding device for sewing machine needle production comprises a rotating shaft, a grinding roller, a limiting ring, a thread screwing block, a first fixing mechanism and an inserting groove. When the grinding device for sewing machine needle production is used, firstly, the grinding roller is taken to be arranged on the rotating shaft in a sleeving mode, one side of the grinding roller makes contact with the limiting ring, then the thread screwing block is taken to be screwed at the end of the rotating shaft, meanwhile, the threaded screwing block makes contact with the grinding roller, and the grinding roller is pressed to be fixed to the rotating shaft; then the first fixing mechanism is taken, a sewing machine needle needing to be ground is woven in a placing groove in a fixed bottom plate, then a thread handle is rotated, and drives a movable sleeve to slide in a second sliding groove through a second sliding rod, the movable sleeve drives a pressing top plate to get close to the fixed bottom plate, and finally a pressing groove is pressed at the outer side of the sewing machine needle; and therefore, the sewing machine needle is fixed into the first fixing mechanism, and then an inserting block on the first fixing mechanism is inserted into the inserting groove.

Owner:重庆市鹏宇五金制品有限责任公司

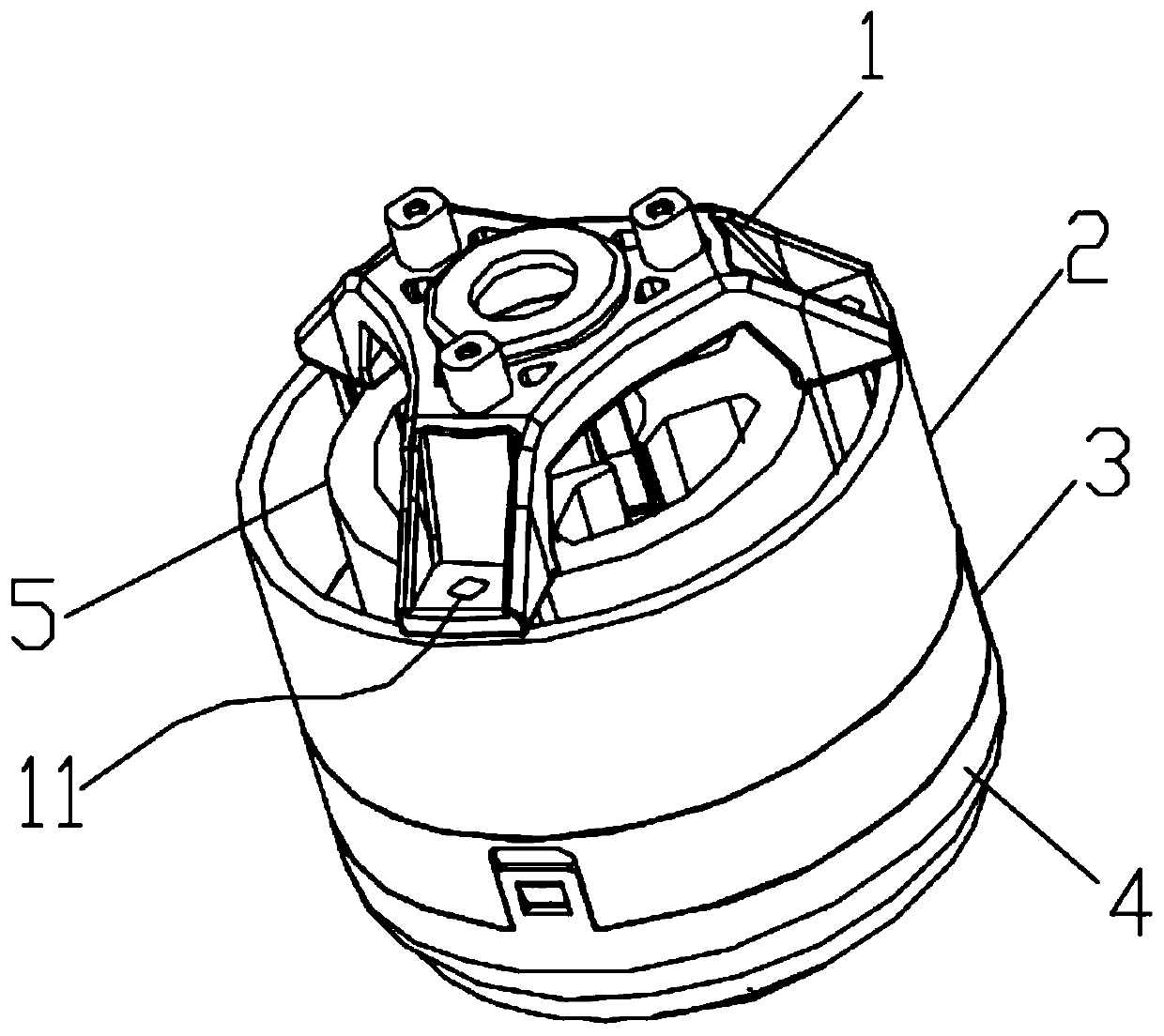

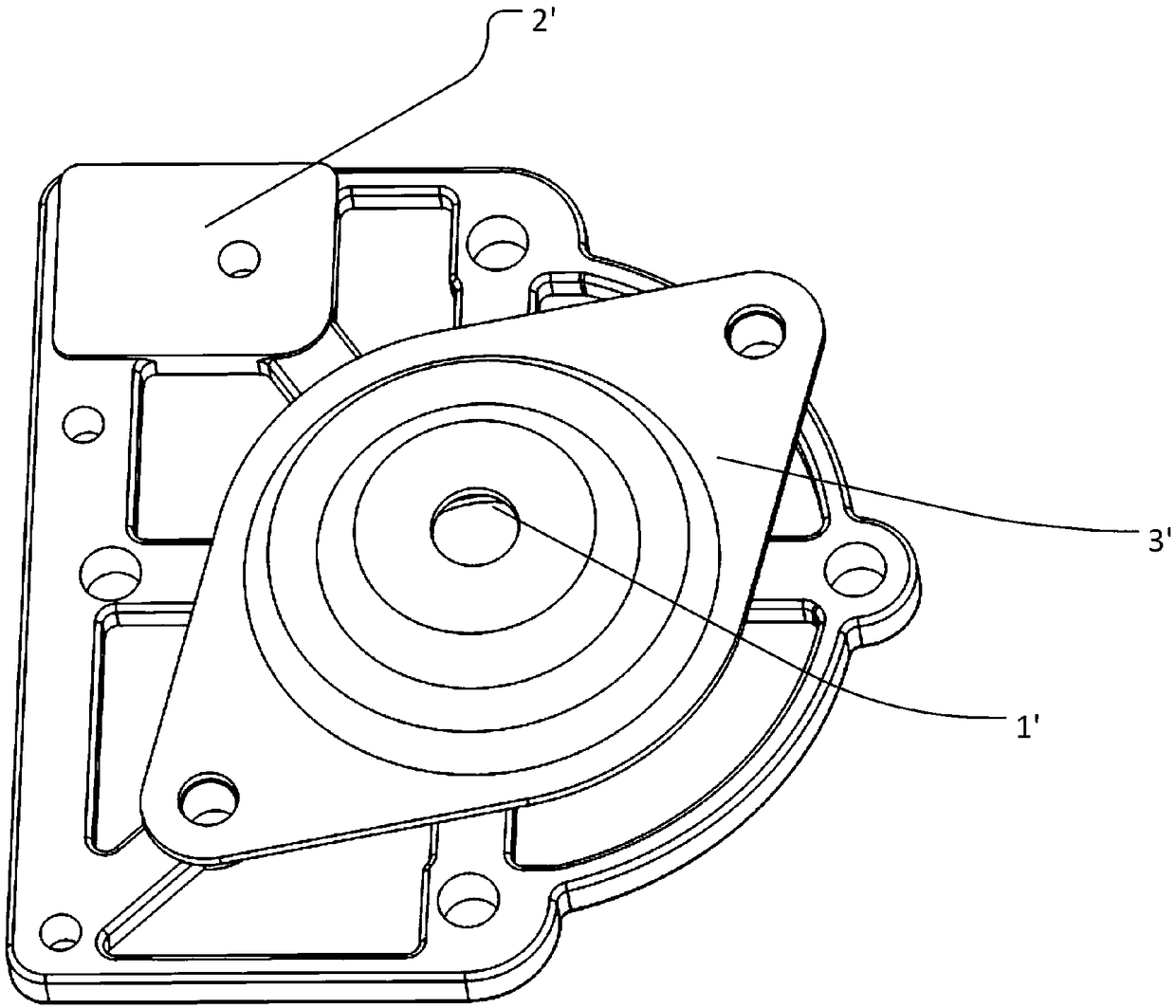

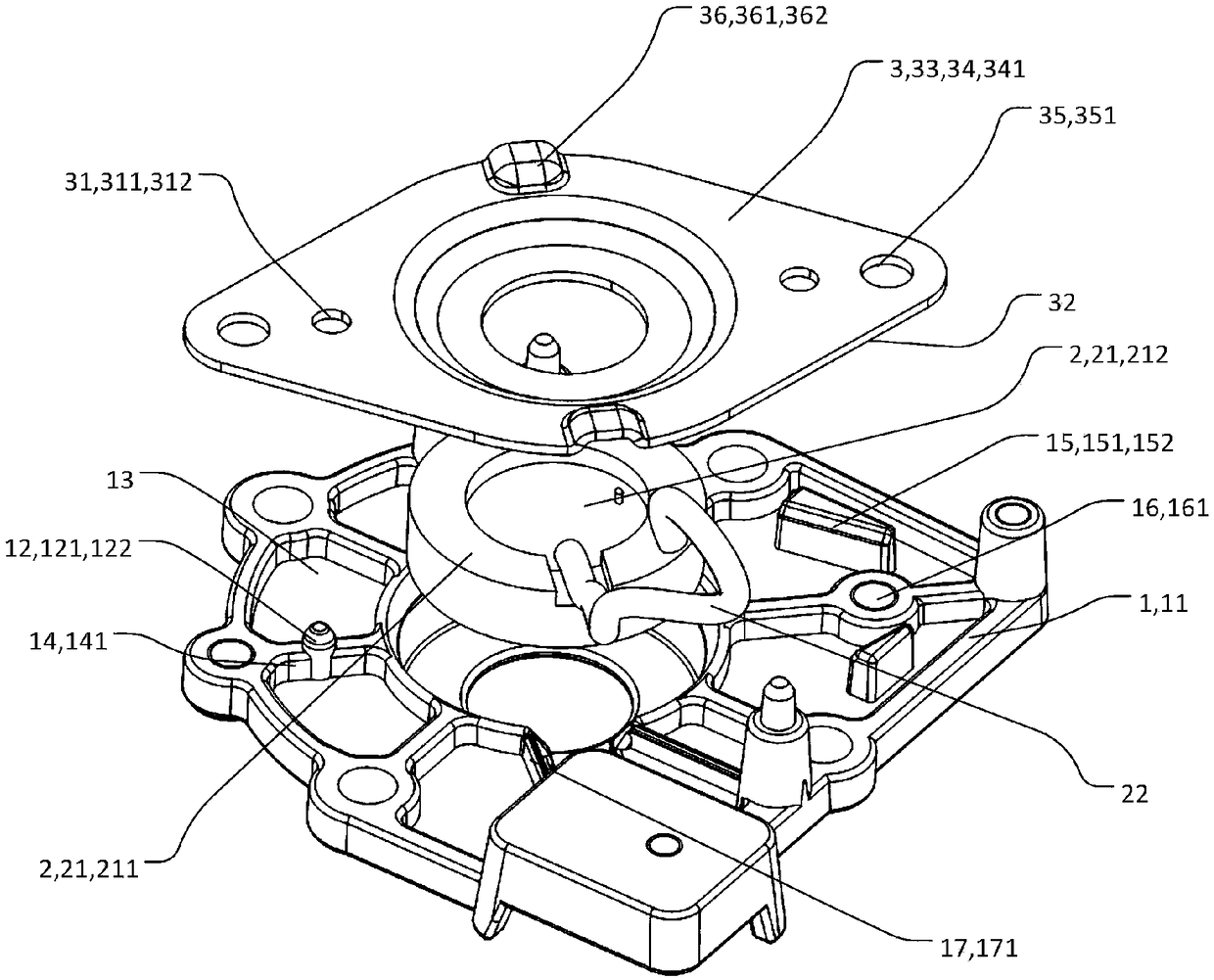

Dust collector motor shell and dust collector motor comprising same

PendingCN110350702AReduce processing stepsReduce processing costsMechanical energy handlingSupports/enclosures/casingsImpellerDust collector

The invention discloses a dust collector motor shell. The dust collector motor shell comprises a motor fixing frame, an upper shell, a cover plate and an outer cover body which are sequentially arranged from top to bottom; a motor containing frame located below the motor fixing frame is arranged in the upper shell; and mounting holes communicated with each other are formed in the motor fixing frame, the motor containing frame and the cover plate sequentially. The dust collector motor shell further comprises a fixed impeller; the fixed impeller comprises a fixed impeller frame body and shielding sheets surrounding the fixed impeller frame body; the shielding sheets are matched with machining positioning opening in the cover plate; the fixed impeller is provided with air guide plates extending towards the motor containing frame; and the air guide plates are matched with air guide blades on the cover plate. The process of the fixation of the dust collector motor shell of the invention toa motor body can be simplified; wind resistance caused by the structure of the motor shell can be reduced; and the air suction effect of a dust collector is remarkably improved.

Owner:地贝电机(苏州)有限公司

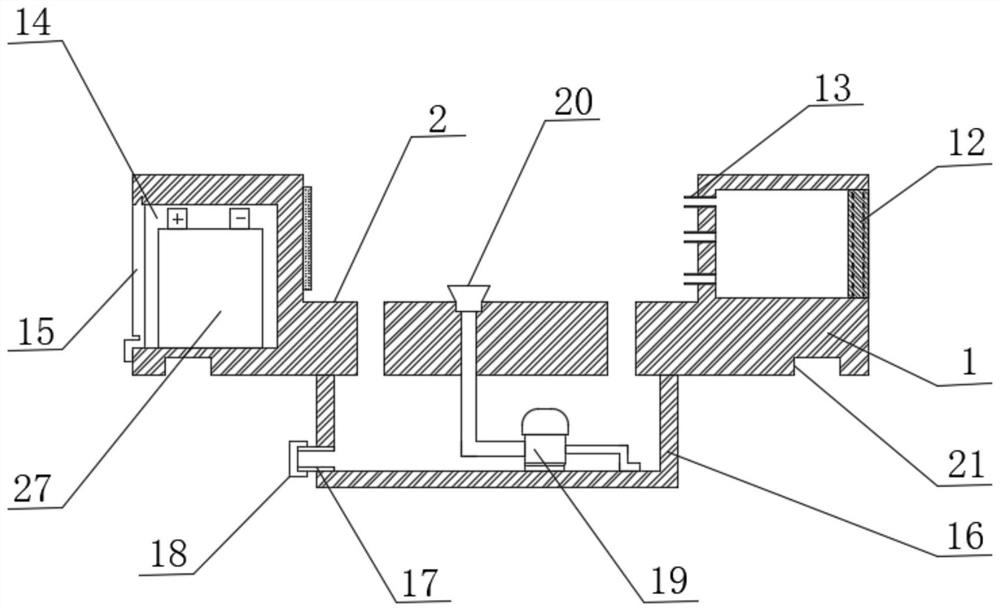

An atomizing element mounting structure of a humidifier and a humidifier

PendingCN109246973AQuick fix connectionAccurate fixed connectionLighting and heating apparatusSupport structure mountingSoftware engineeringDormancy

The invention provides an atomizing element mounting structure of a humidifier and a humidifier, which are used for fixedly mounting the atomizing element between the heat dissipation structure of thehumidifier and the pressure piece. The mounting structure includes a first positioning structure and / or a first anti-dumb structure disposed on the heat dissipation structure, and a second positioning structure and / or a second anti-dormancy structure correspondingly disposed on the pressing member, wherein the first positioning structure cooperates with the second positioning structure to realizethe positioning between the heat dissipation structure and the pressing member, and the first anti-dormancy structure cooperates with the second anti-dormancy structure to realize the anti-dormancy installation between the heat dissipation structure and the pressing member. The humidifier of the present invention fixedly installs the atomizing element between the heat dissipation structure and the pressure piece through the mounting structure, thereby solving the problems of low mounting efficiency, poor mounting accuracy and unguaranteed sealing effect existing in the existing mounting structure during the mounting process, and improving the assembly efficiency, the assembly reliability and the sealing effect.

Owner:GREE ELECTRIC APPLIANCES INC

Quick mounting and fixing structure used on faucet base

Owner:浙江安玛卫浴有限公司

A counterweight device for towed line array and towed line array

ActiveCN104047994BRealize fixed depthImprove detection performanceWave based measurement systemsCounterweightsSEMI-CIRCLEHalf field

The present invention provides a counterweight device for a towed line array and a towed line array, comprising: a first semi-cylindrical counterweight and a second semi-cylindrical counterweight with a semi-circular section, Buckle type locking mechanism, first hinge; a contact surface of the first semi-cylindrical counterweight and the second semi-cylindrical counterweight is connected through the first hinge, when the first semi-cylindrical counterweight When the opening angle of the counterweight and the second semi-cylindrical counterweight is zero, the two counterweights cooperate with each other to form a hollow cylinder. When the first semi-cylindrical counterweight and the second semi-cylindrical counterweight are opened into It is used to place the towing cable to the hollow part of the above-mentioned cylinder when the angle is at an angle; A streamer placed closely on the hollow part; wherein, the cylinder ends of the first semi-cylindrical counterweight and the second semi-cylindrical counterweight are also provided with a first conical guide section.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Magic tape

Owner:DONGGUAN HONGSHENG WEAVING

Component connecting structure and display base connecting device

InactiveCN106678133AQuick fix connectionShorten the timeSecuring devicesStands/trestlesDisplay deviceEngineering

Owner:TIANJIN SAMSUNG ELECTRONICS CO LTD +1

Shaft liner structure and automatic teller machine

PendingCN106960508AEasy to separateQuick fix connectionComplete banking machinesCoin/currency accepting devicesEngineeringMechanical engineering

The invention discloses a shaft liner structure and an automatic teller machine, and belongs to the financial equipment technology field. The shaft liner structure comprises a shaft liner body, a limiting column, and a clamping groove. The shaft liner body is provided with a through hole used for accommodating a shaft and a bayonet used for clamping a separating shaft in the through hole. The limiting column is disposed in the through hole, and is fixedly connected with the shaft liner body. The clamping groove is extended from the outer side surface of the shaft liner body to the inner side surface of the shaft liner body along the radial direction of the shaft liner body. By arranging the through hole and the bayonet in the shaft liner body, the rapid clamping connection and the rapid separation of the shaft liner body and the separation shaft are realized, and therefore the problem of the repairing of the shaft liner requiring the dismounting of all components of the separating shaft is solved. The axial positioning of the separating shaft and the shaft liner structure is realized by the limiting column, and the positioning is simple. Fixed connection between a tongue piece and the shaft liner structure is realized by the clamping groove, and the installation stability of the tongue piece is good. The invention also provides the automatic teller machine comprising the above mentioned shaft liner structure.

Owner:SHENZHEN YIHUA COMP +2

Fixing support for coating machine

InactiveCN111853494AAvoid dust accumulationEasy to cleanVacuum evaporation coatingSputtering coatingEngineeringStructural engineering

The invention relates to the technical field of vacuum coating machines, and discloses a fixing support for a coating machine. The fixing support comprises a base; a collecting groove is formed in themiddle of the upper surface of the base, the four corners of the upper surface of the base are fixedly connected with supporting columns correspondingly, and positioning grooves are formed in the upper surfaces of the supporting columns; the inner bottom walls of the positioning grooves are fixedly connected with damping springs, and the tops of the damping springs are fixedly connected with supporting rods; the tops of the supporting rods are fixedly connected with clamping blocks, and threaded holes are formed in the four corners of the upper surfaces of the clamping blocks correspondingly;and the threaded holes are in threaded connection with bolts, and the clamping blocks are fixedly connected with the coating machine through the threaded holes and the bolts. According to the fixingsupport for the coating machine, through the positioning grooves, an adhesive plate, a miniature fan and a gas conveying pipe on the base, dust at the bottom of the coating machine can be blown down,then the blown-down dust is collected to the bottom of the collecting groove, the dust is adsorbed through the adhesive plate on the inner side wall of the collecting groove, and then the dust is prevented from escaping in air.

Owner:浙江捷菱智能装备有限公司

A method for quickly erecting the main cables of a suspension bridge

ActiveCN105113414BReduced traction requirementsGood choiceSuspension bridgeBridge structural detailsTerrainTraction system

The invention discloses a method for quickly setting up main ropes of a suspension bridge. The method comprises the steps that one main rope is straightened and looped; a traction system is arranged; the movable end of the main rope is pulled to the opposite bank, and temporary connection is carried out; the traction system is transformed, a fixed pulley block and a movable pulley block are used for continuing to pull the movable end of the main rope to the design position; a fork lug type adjusting lock is manually adjusted, and the vector of the main rope is adjusted to the design requirement; and the rest of main ropes continue to be set up according to the above steps. According to the method, the traction cost of the main ropes of the cableway bridge is greatly reduced, work efficiency is improved, and the method is particularly suitable for traction of main ropes of cableway bridges of various spans, widths and main rope tensions in various precipitous-terrain places with traffic inconvenience.

Owner:NO 7 ENG CO OF CHINA RAILWAY NO 8 ENG GRP CO LTD

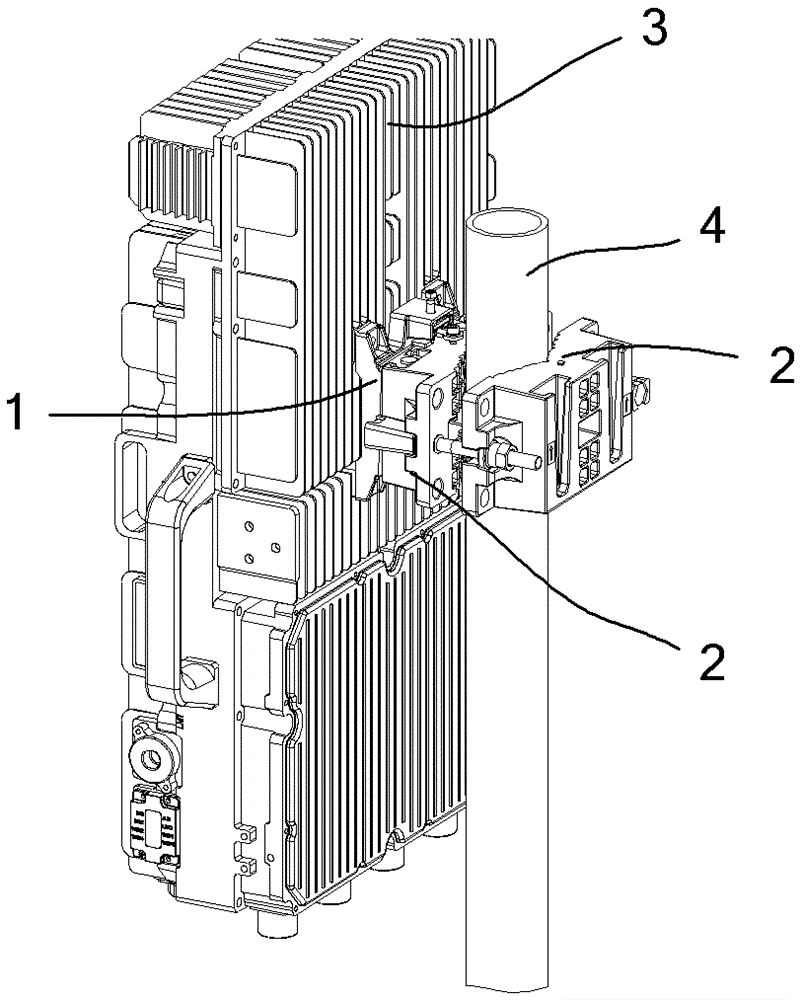

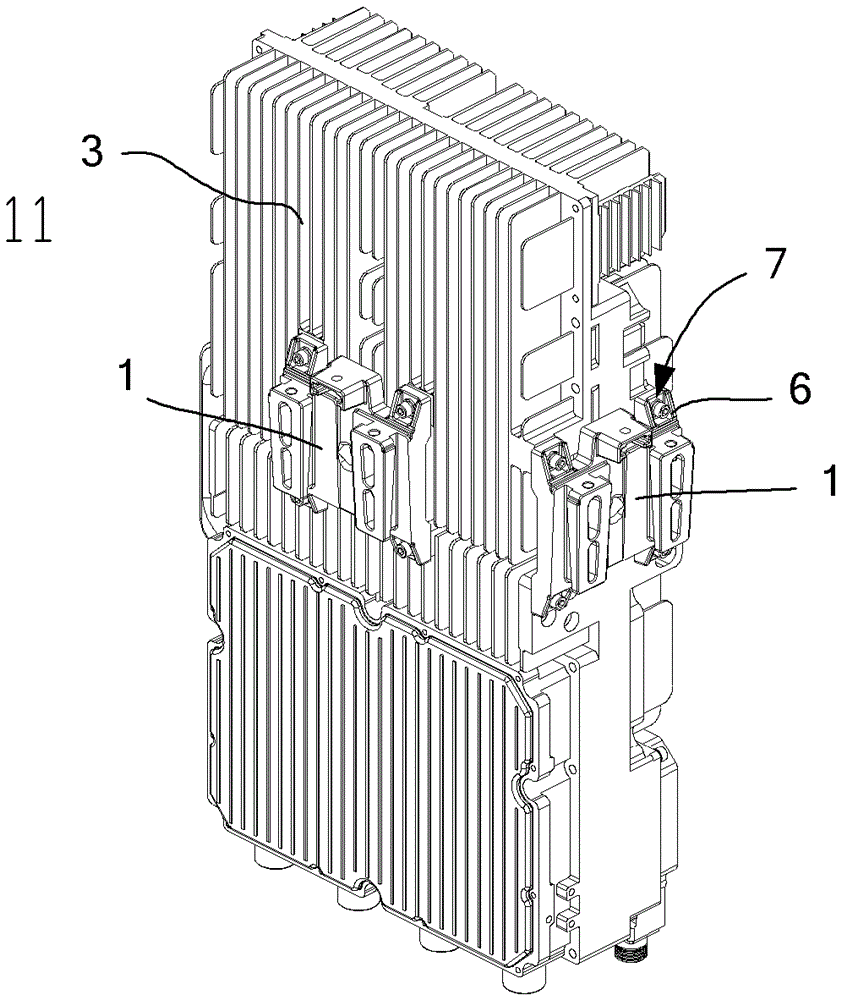

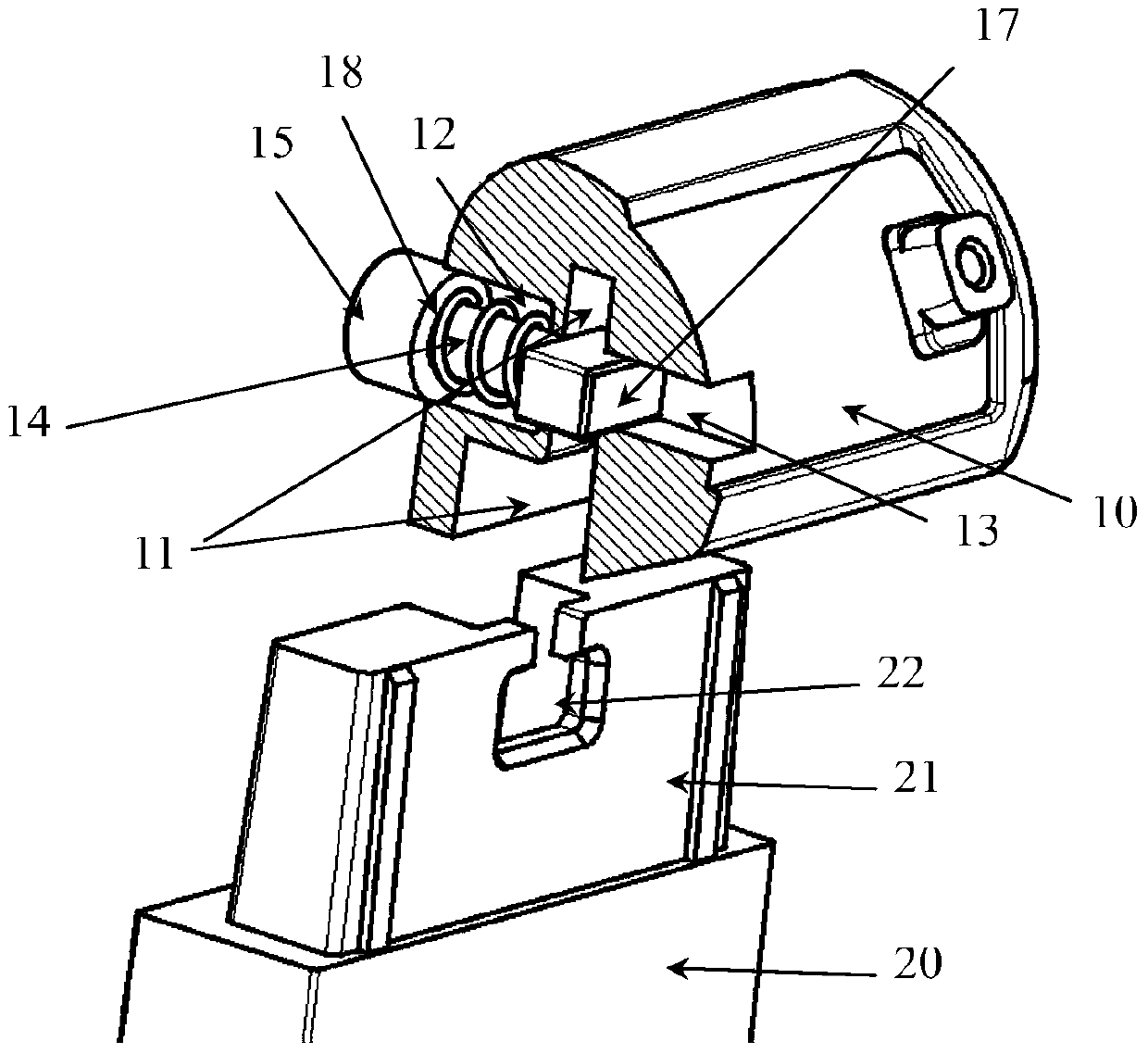

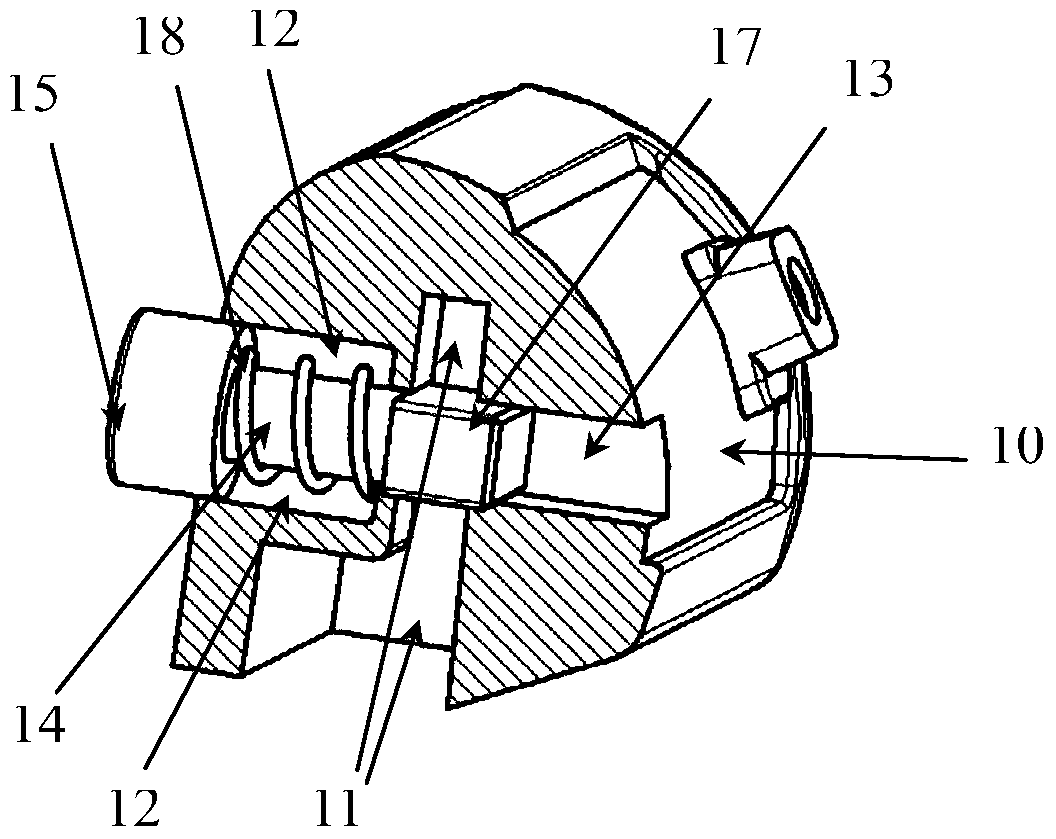

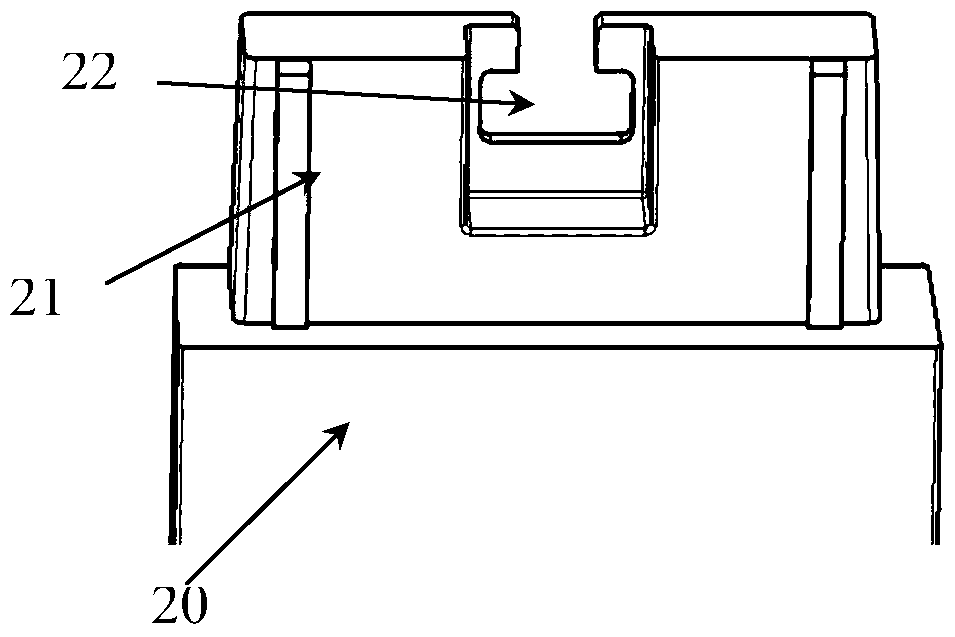

A quick installation device for rru radio frequency module

ActiveCN102088799BQuick fix connectionQuick installationMachine supportsSheet joiningRF moduleComputer engineering

The invention provides a quick installation device for an RRU radio frequency module, comprising: an adapter plate, one side of the adapter plate is fixedly connected to the RRU radio frequency module, and the other side is provided with a mounting block for fast mounting on a clamping part; A fastening piece, one side of the fastening piece is matched with the fixed object, and the other side is provided with a hanging groove matching the hanging block. The present invention adopts the adapter board and the clamping part, the quick fixed connection between the adapter board and the RRU radio frequency module, the fast fixed connection between the clamping part and the fixed object, and then the adapter board is quickly mounted on the RRU radio frequency module with the RRU radio frequency module. On the clamping parts, the RRU radio frequency module can be quickly installed on the fixed object, with strong versatility, high efficiency, saving a lot of manpower and material resources, and the installation is reliable.

Owner:ZTE CORP

A component connection structure and a display base connection device

InactiveCN106678133BQuick fix connectionShorten the timeTelevision system detailsColor television detailsDisplay device

Owner:TIANJIN SAMSUNG ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com