Round-tunnel double-layer lane frame structure system and full-prefabricated construction method thereof

A frame structure and construction method technology, applied to roads, roads, buildings, etc., can solve the problems of low prefabrication, achieve good seismic performance, fast speed, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

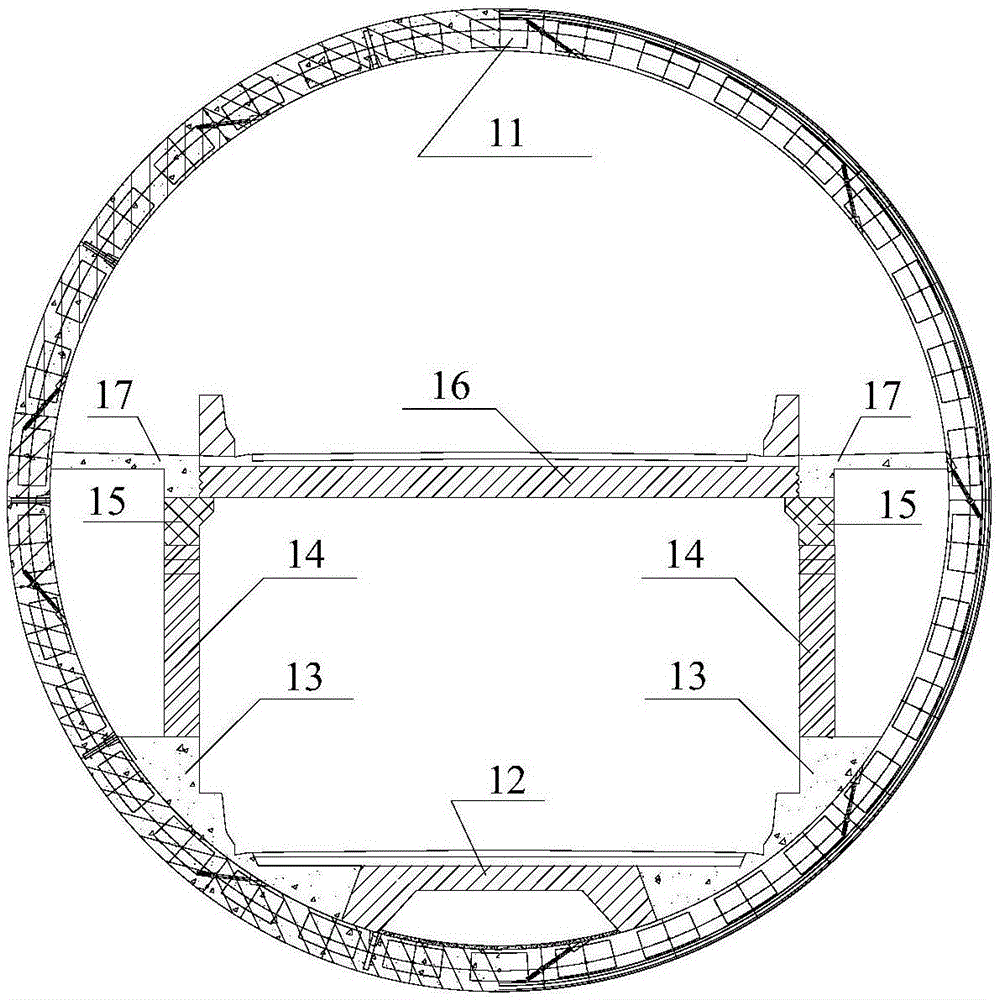

[0028] Please refer to Figure 1-3 , the present embodiment 1 provides a fully prefabricated construction method for a circular tunnel double-layer driveway frame structure system, including the following steps:

[0029] Step 1, forming the construction steps of the circular tunnel 11;

[0030] Step 2, hoisting the prefabricated lower lane component 12 at the bottom of the circular tunnel 11, pouring concrete on both sides of the prefabricated lower lane component 12, so that the prefabricated lower lane component 12 is fixedly arranged at the bottom of the circular tunnel 11, forming the lower lane structure system;

[0031] Step 3, pouring the base 13 of the upper driveway frame structure system on both sides of the circular tunnel 11 and above the prefabricated lower driveway component 12;

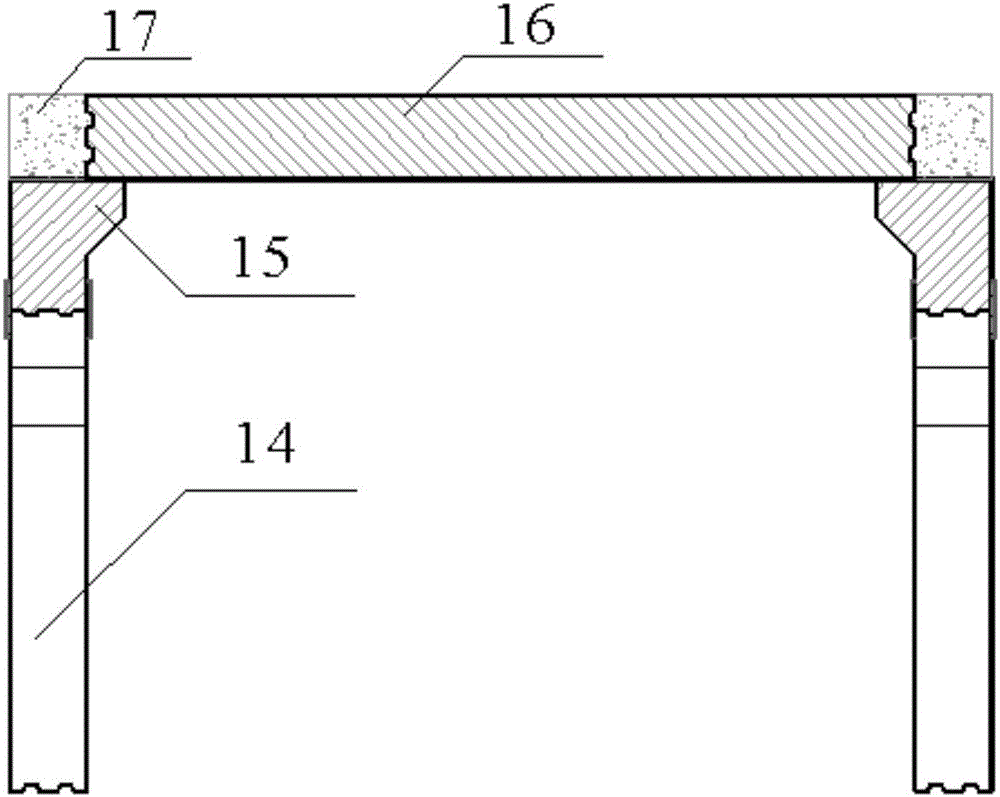

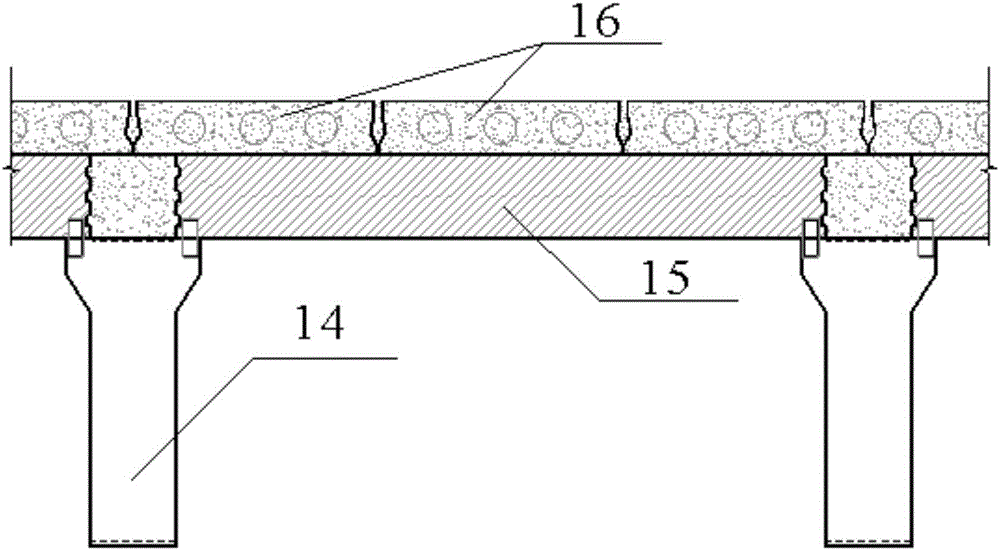

[0032] Step 4, assembling the prefabricated corbel column 14 perpendicular to the base 13;

[0033] Step 5, assembling the prefabricated corbel longitudinal beam 15 on the prefabrica...

Embodiment 2

[0042] Please refer to Figure 1-3 , the present embodiment 2 provides a circular tunnel double-layer lane frame structure system, including a round tunnel 11, and a prefabricated lower lane member 12 is fixedly arranged at the bottom of the round tunnel 11 to form a lower lane structure system; on both sides of the round tunnel 11 and The pedestal 13 of the upper driveway frame structure system formed by pouring above the prefabricated lower driveway component 12, each base 13 is vertically fixedly connected with a prefabricated corbel column 14, and each prefabricated corbel column 14 is fixedly connected with a prefabricated cattle The leg stringers 15 are fixedly connected with the prefabricated upper driveway slabs 16 on the prefabricated corbels 15 on both sides to form the frame structure system of the upper driveway.

[0043] As a preferred embodiment, the present invention provides a circular tunnel double-layer driveway frame structure system, the prefabricated lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com