Broken nail extractor

A technology for extractors and broken nails, applied in the direction of fixers, etc., can solve the problems of low work efficiency, large volume, large bone damage, etc., and achieve the effect of convenient operation, simple structure, and good docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

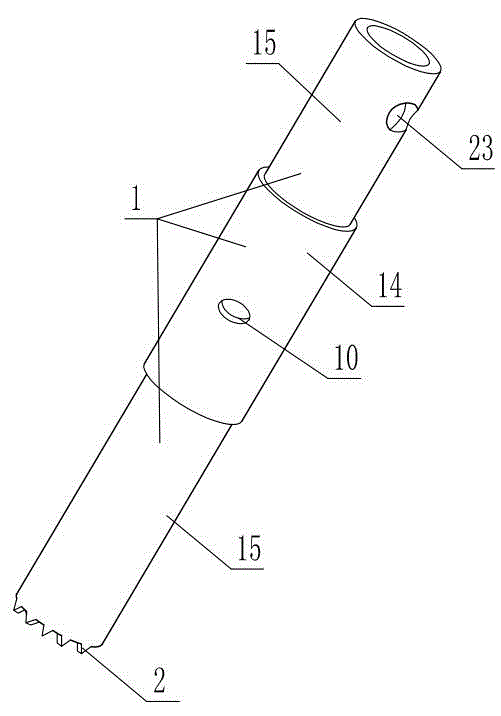

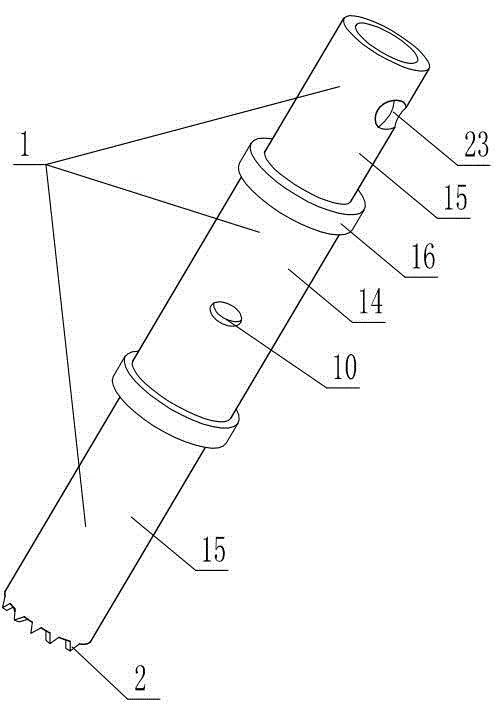

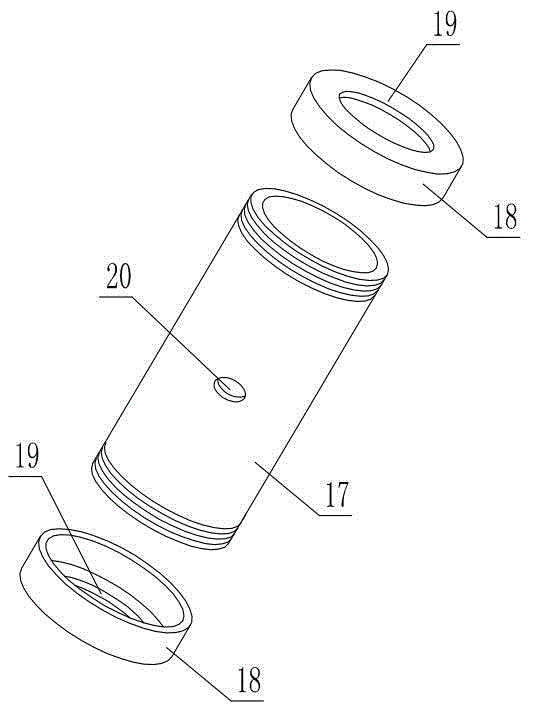

[0046] As shown in the figure, the broken nail remover includes a round tube 1 with a milling port and a locking port. The ring of the milling port of the round tube is provided with milling teeth 2 extending downward. Part 3, the inner cylinder 4 with the mouth downwards is inserted in the round tube, the spacer ring at the mouth of the inner cylinder is provided with a clip 5 extending downward and gradually stretched outward, and the inner wall of the clip is provided with an axially extending clip Teeth 7, the lower ends of the clips are all located on the axial extension track of the circular pipe, the upper end of the inner cylinder is fixed with a polygonal column 8, the middle part of the inner cylinder is provided with an external thread 9, and the middle part of the inner wall of the circular pipe is provided with an internal thread that is screwed with the external thread. Thread 6.

[0047] The round tube is a hollow tube with two ports. For the convenience of desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com