Fireproof door quick mounting structure

An installation structure and technology for fire doors, applied in the field of fire doors, can solve the problems of troublesome installation and time-consuming, and achieve the effects of easy cleaning, shortening installation time, and convenient and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

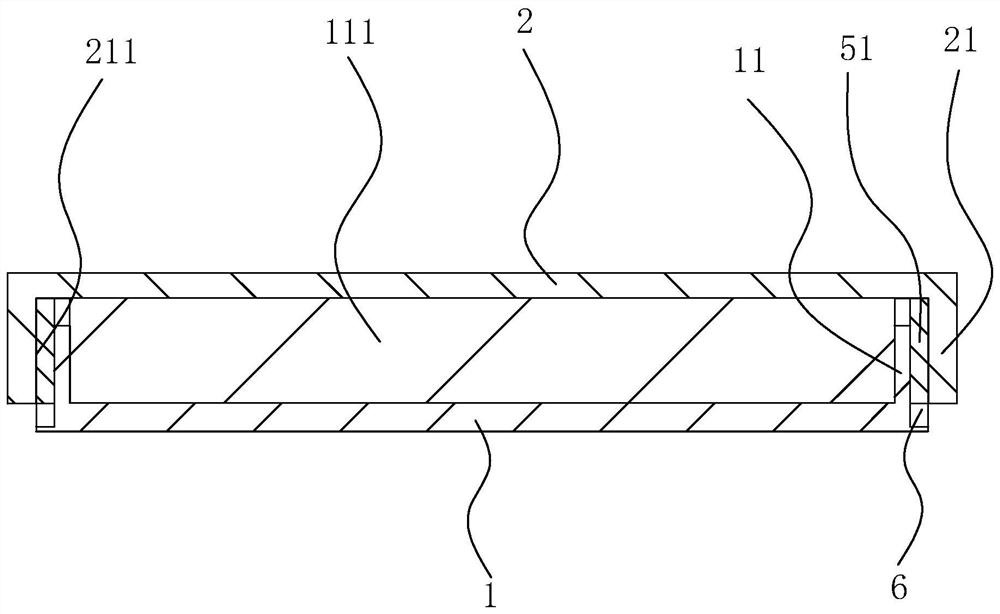

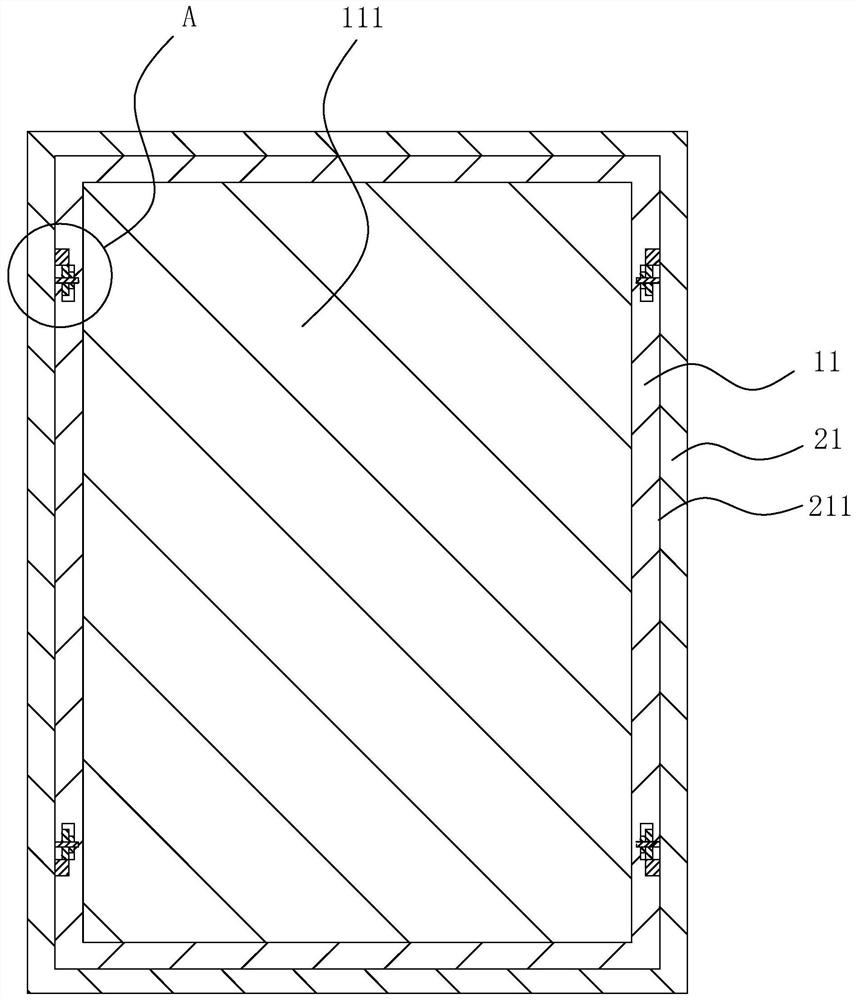

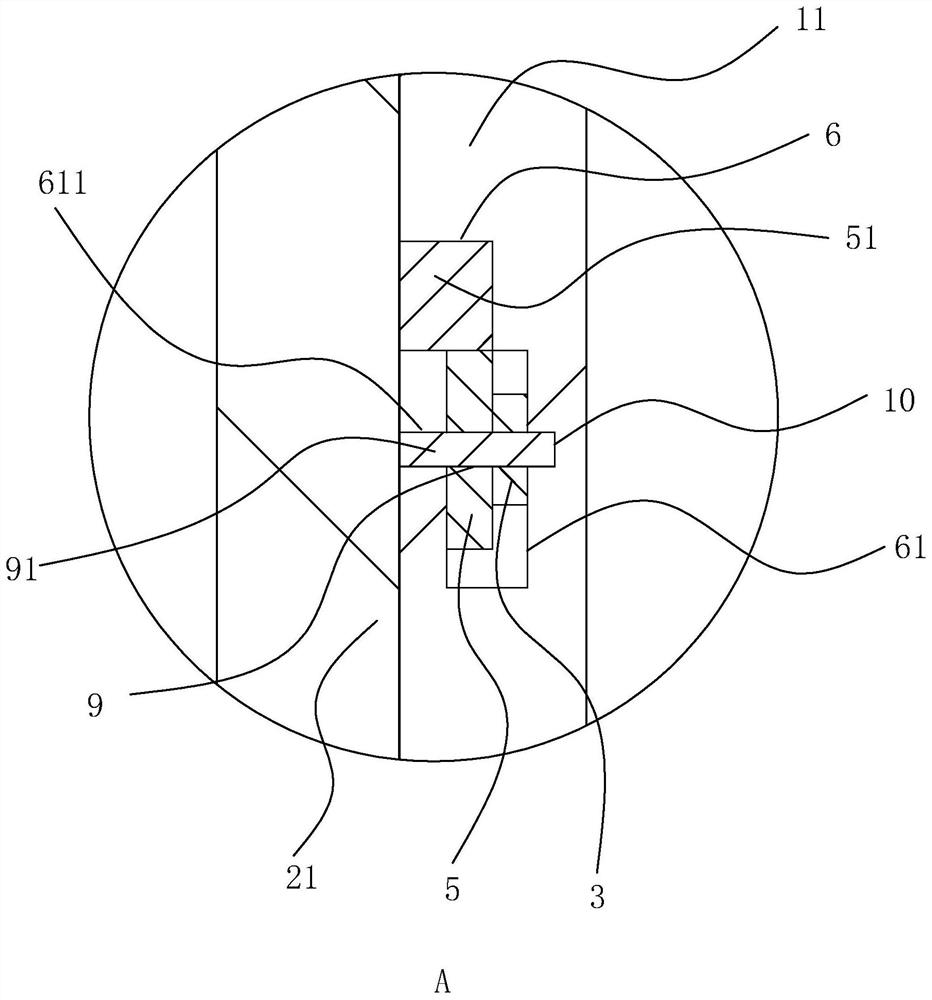

[0037] refer to Figure 1 to Figure 4, is a quick installation structure for a fireproof door disclosed in the present application, including a first door panel 1 and a second door panel 2, the first door panel 1 and the second door panel 2 are arranged parallel to each other, and the first door panel 1 faces one side of the second door panel 2 The first installation plate 11 is arranged symmetrically by bending, the length direction of the first installation plate 11 is arranged along the length direction of the first door panel 1, and the second door panel 2 is provided with a second door panel 2 facing the side of the first door panel 1 through bending. Mounting plate 21, the length direction of the second mounting plate 21 is arranged along the length direction of the second door panel 2; Between the second mounting plate 21, form a connection groove 211 for the insertion of the first mounting plate 11, the inner side wall of the connection groove 211 and The outer sidewal...

Embodiment 2

[0044] refer to Figure 5 , the embodiment of the present application also discloses a quick installation structure for a fire door. The length direction is set along the height direction of the first mounting plate 11, the first mounting groove 112 is provided with a rivet 10, the rivet 10 can slide in the first mounting groove 112, and the second mounting plate 21 is symmetrically provided with a rivet 10 Insert and slide the second mounting groove 212, the length direction of the second mounting groove 212 is set along the length direction of the second mounting plate 21; when installing between the first mounting plate 11 and the second mounting plate 21, the The rivet 10 is inserted into the first installation groove 112 and the second installation groove 212 at the same time, and according to the actual bonding degree of the first installation board 11 and the second installation board 21, the rivet 10 can be inserted between the first installation board 11 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com