Micro rotary locking device

A locking device and locking technology, applied in the direction of coupling device, parts of connecting device, electrical components, etc., can solve the problems of heavy weight, large packaging size of locking mechanism, redundant steps, etc., and achieve small occupation size and structure. Ingenious, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed description will be made below in conjunction with the accompanying drawings and preferred embodiments.

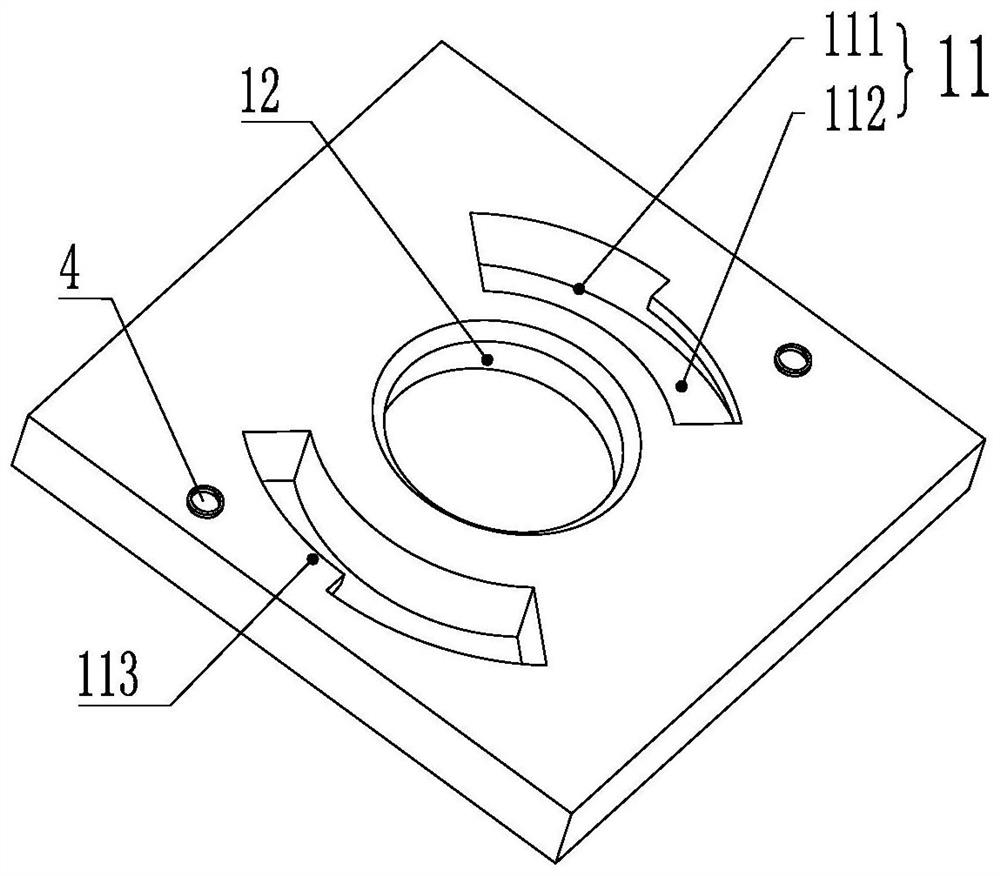

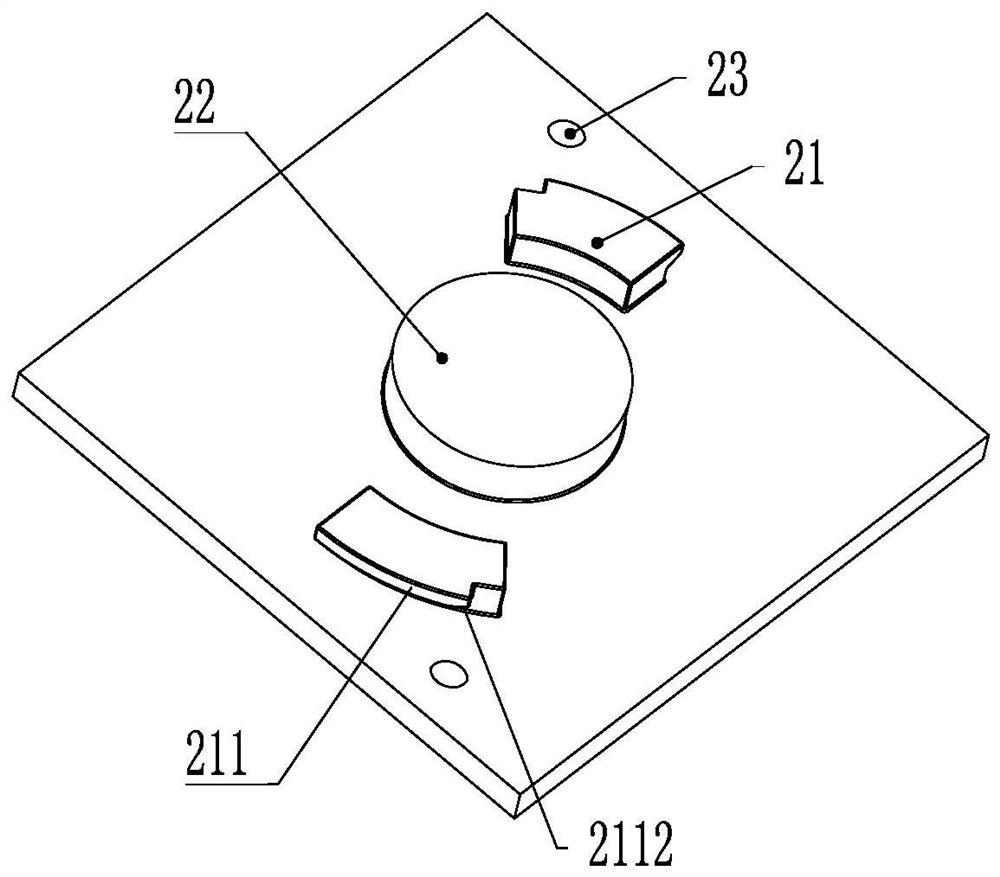

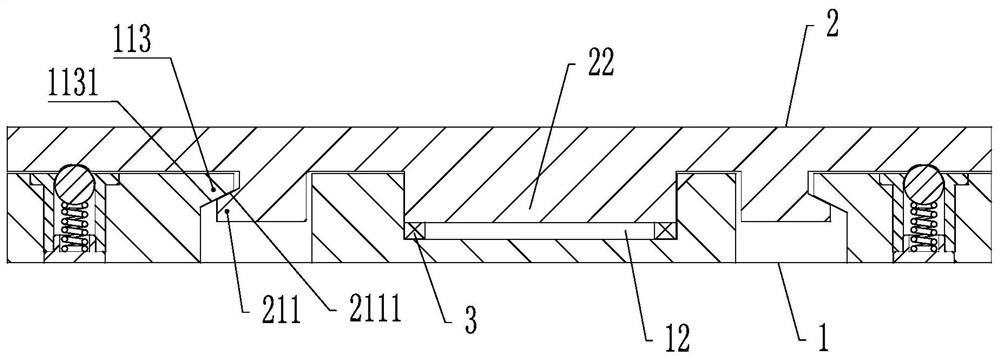

[0025] An embodiment of a miniaturized rotary locking device of the present invention is Figure 1 to Figure 4 As shown, a miniaturized rotary locking device includes a locking fixed end 1 and a rotating movable end 2 that are engaged in relative rotation to achieve mutual locking, with the locking mating ends of the locking fixed end and the rotating movable end as their respective front ends; At least one swivel groove 11 is provided on the locking fixed end, and the swivel groove 11 is an arc-shaped groove. Preferably, there are two swivel grooves arranged symmetrically on both sides of the locking fixed end, so as to achieve a stable locking fit relationship The screwing groove includes a connected initial section 111 and a locking section 112. The inner wall of the front end of the locking section 112 has a stopper 113 extending toward the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com