Steel-concrete bridge body and assembling construction process thereof

A construction technology and concrete technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems affecting positioning reliability, inconvenient positioning adjustment, easy to shift, etc., to ensure reliability, ensure assembly effect, and improve positioning The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

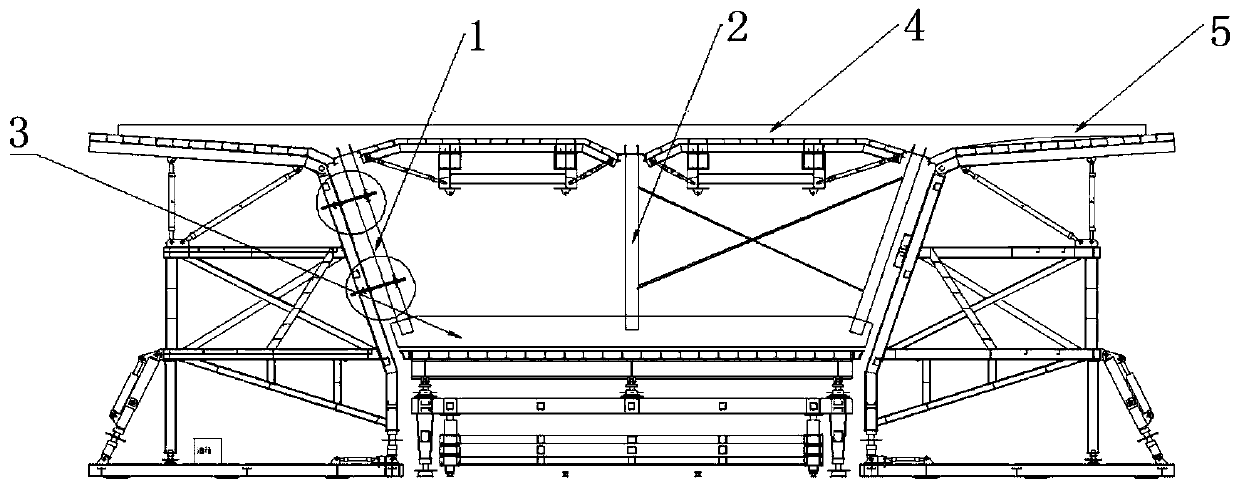

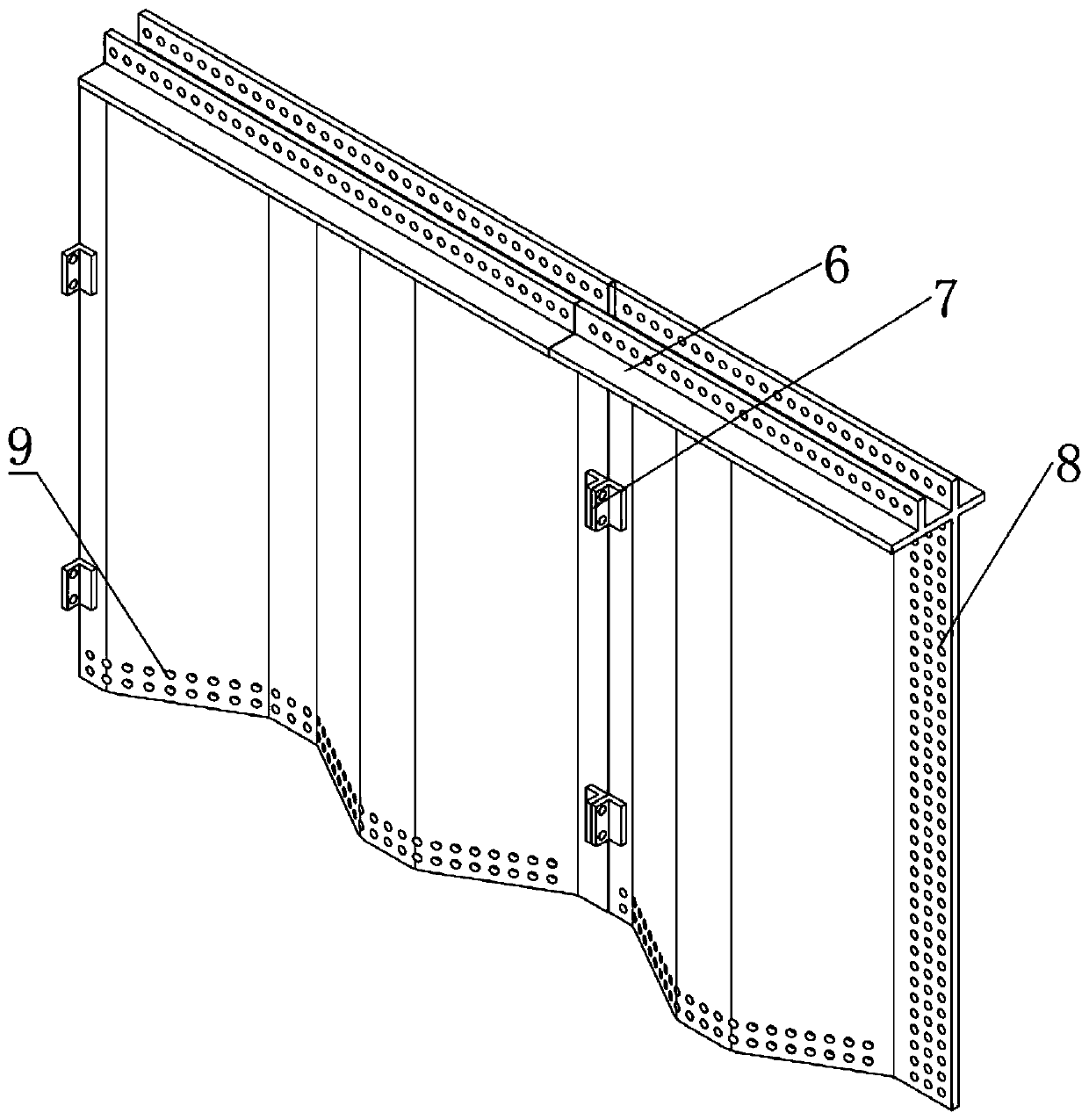

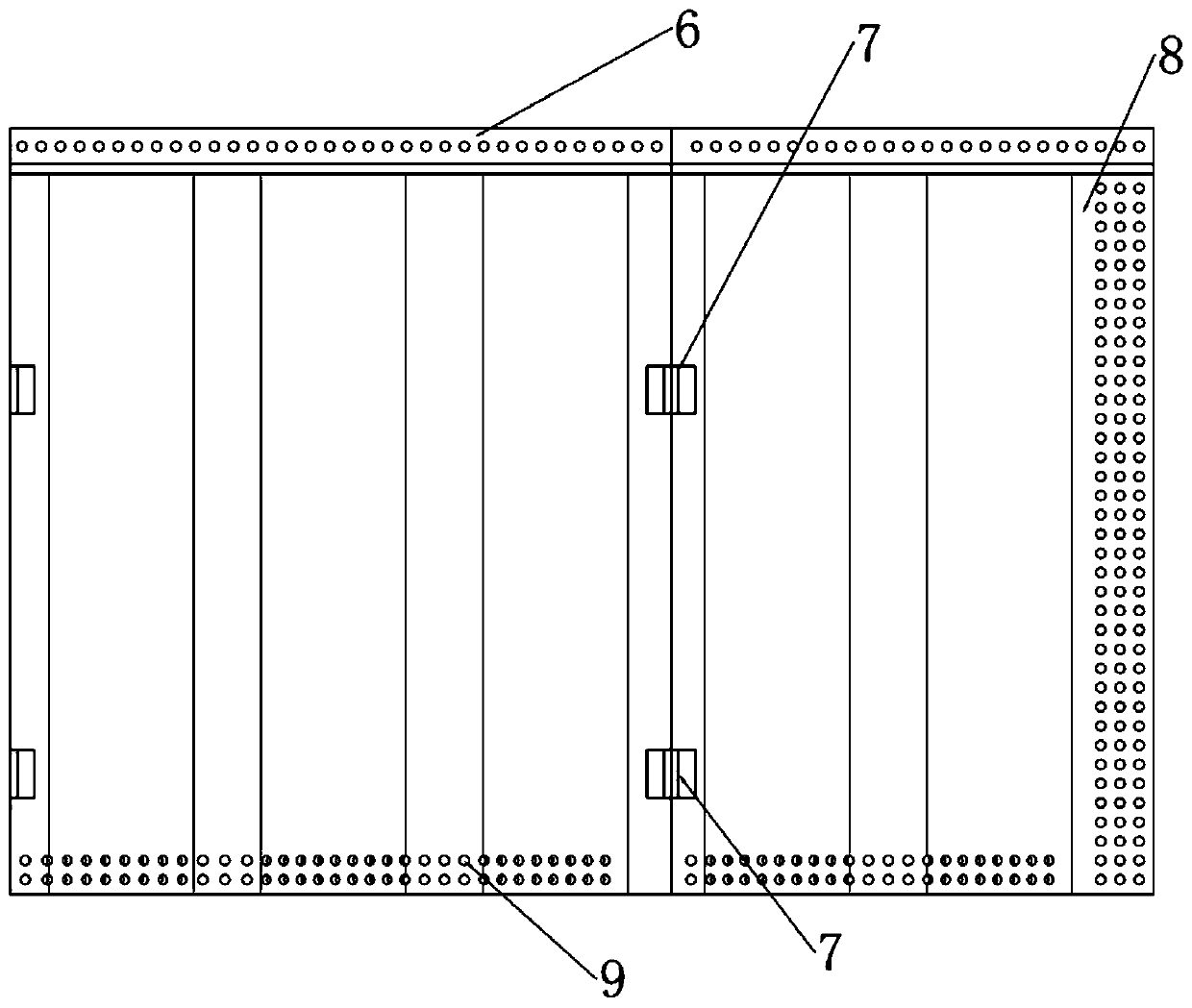

[0027] Such as Figure 1-4 As shown, the present invention provides a steel-concrete bridge girder, which is characterized in that: the girder is a composite girder formed by longitudinally connecting a plurality of prefabricated segmental box girders, and the segmental box girders include a concrete roof 4. The concrete floor 3, the middle web 2 vertically arranged in the middle of the section box girder and the side webs 1 symmetrically arranged on both lateral sides of the concrete floor 3, the middle web 2 and the side web 1 All are corrugated steel webs, and temporary matching parts 7 are fixed on the sides of the corrugated stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com