Dust collector motor shell and dust collector motor comprising same

A technology for motor shells and vacuum cleaners, applied in the field of vacuum cleaner motor shells and vacuum cleaner motors, which can solve problems such as affecting the suction force, bursting of the outer shell, and increasing wind resistance, so as to improve processing efficiency, reduce processing costs, and reduce processing steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

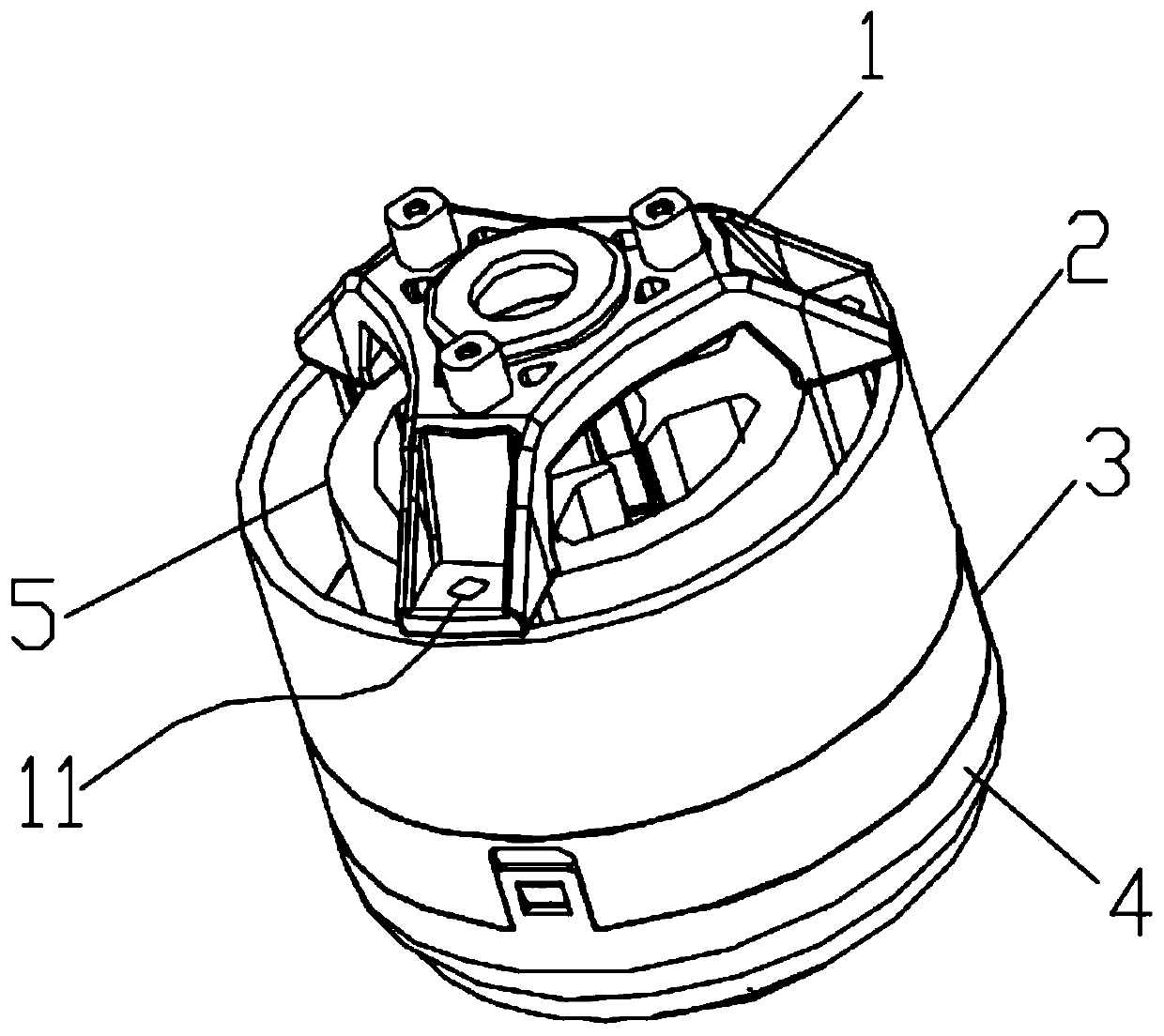

[0027] see figure 1 As shown, the motor casing of the vacuum cleaner in this embodiment includes a motor fixing frame 1, an upper casing 2, a cover plate 3 and an outer cover body 4 arranged in sequence from top to bottom, and inside the upper casing 2, it is located on the motor fixing frame 1 is provided with a motor housing frame 5 below. The upper casing 2 is snapped connected with the cover 3 , and the outer cover 4 is snapped on the side wall of the cover 3 .

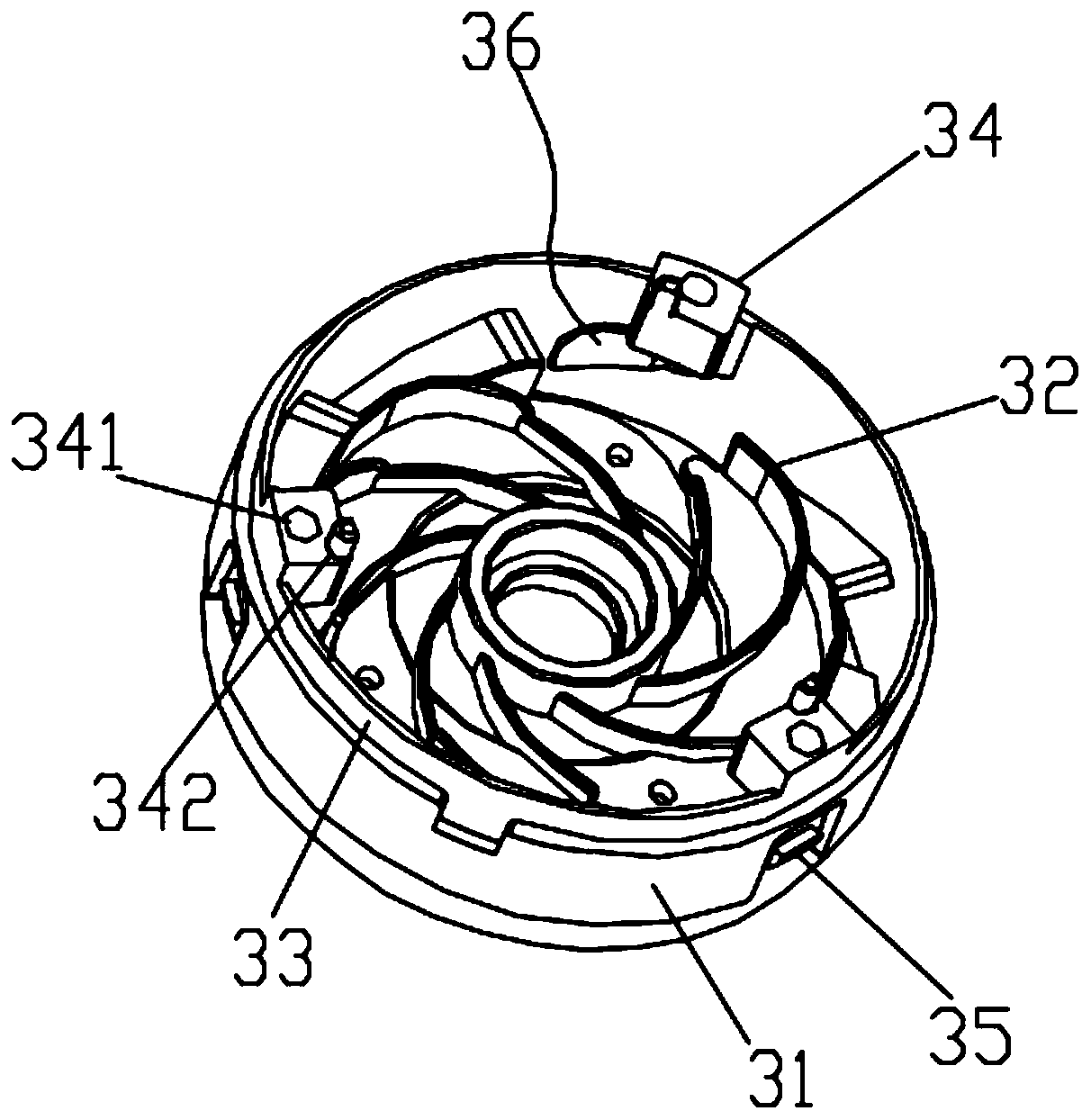

[0028] see figure 2 As shown, along the circumferential direction of the cover plate 3, a cover plate side wall 31 extending from the lower edge of the upper housing 2 is provided. The inner side of one end (i.e. the lower end in this embodiment) is provided with a number of helically distributed wind guide vanes 32, forming a spiral air guide channel in the middle of each wind guide vane 32, so that the air sucked by the motor can pass along the The air guide channel is sucked in quickly. The upper edge of t...

Embodiment 2

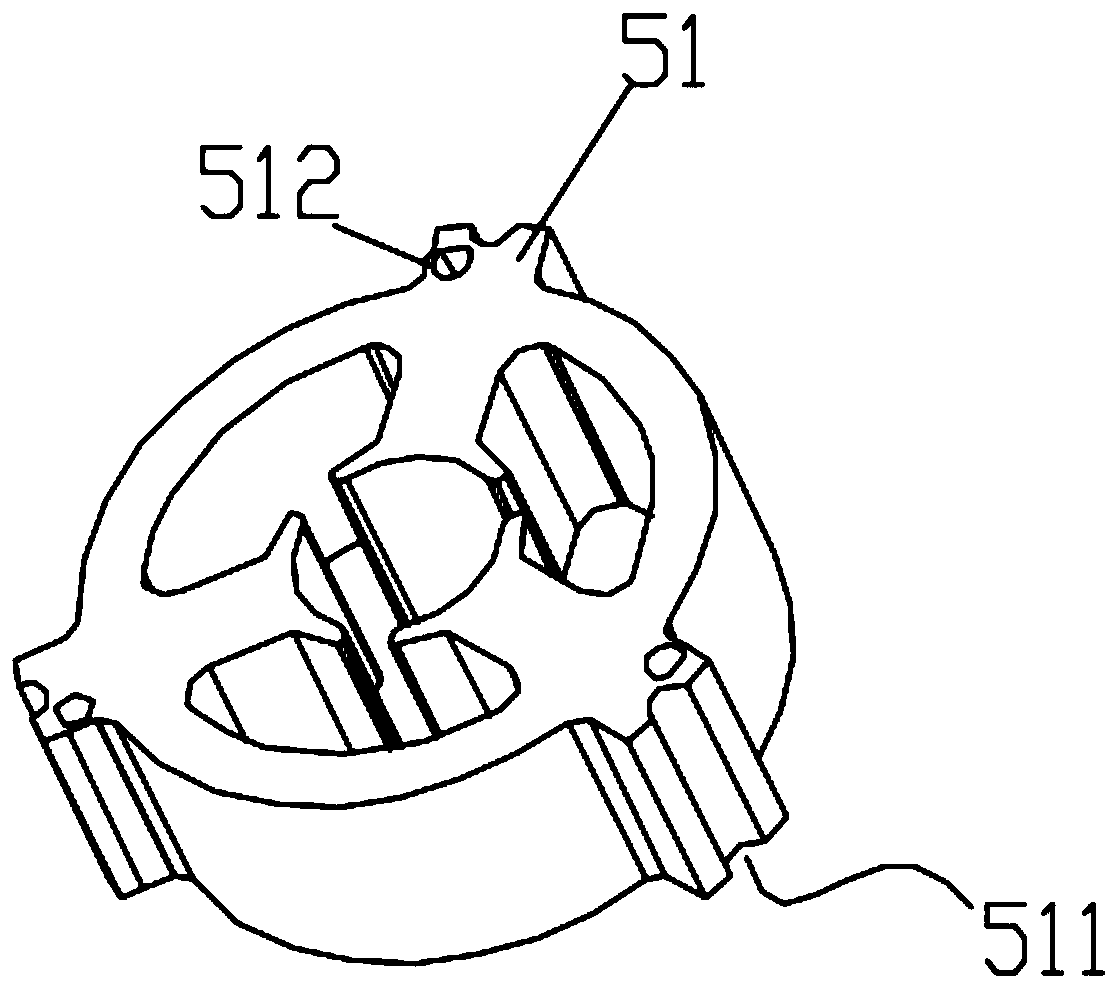

[0036] see Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the connecting ear 51 of the motor housing frame 5 is provided with a second mounting hole that communicates with the first mounting hole 341, and the second mounting hole is connected to the first mounting hole 341. It is arranged coaxially with the third mounting hole 11 and the diameters of the three holes are consistent, that is, the second mounting hole is directly opened on the connecting ear 51 , and correspondingly, there is no need to set the second slot 21 on the upper shell 2 . There is clearance fit between the outer edge of the connecting ear 51 and the upper shell 2 . The structure of the motor accommodating frame 5 in this embodiment is more convenient for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com