Automatic fastening screw

A screw, fastening technology, applied in the field of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

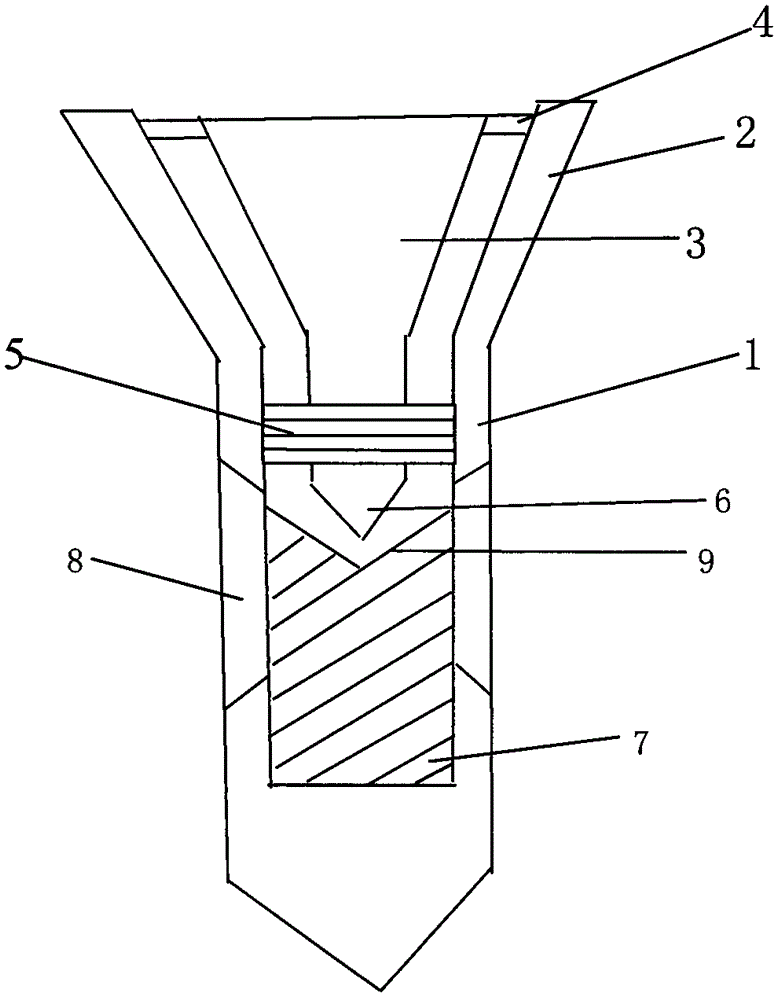

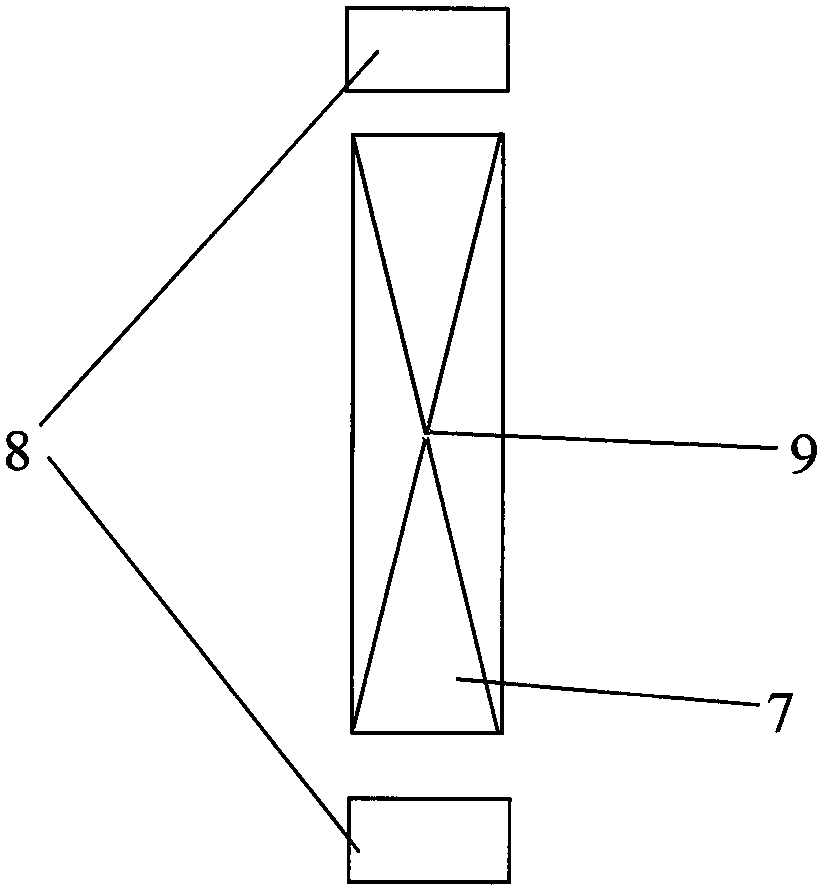

[0016] The automatic fastening screw of the present invention has a hollow outer nail body 1, an external screw thread is arranged outside the outer nail body 1, a hollow outer nail cap 2 is arranged on the top of the outer nail body 1; Expansion piece 7, the upper end of expansion piece 7 is provided with V-shaped groove 9; Cooperate expansion piece 7 is provided with expansion groove 8 on outer nail body 1 side, can stretch out from expansion groove 8 when expansion piece 7 expands; Outer nail cap 2 and The hollow structure of the outer nail body 1 is also provided with a solid inner nail body 3, the bottom end of the inner nail body 3 has a protruding inner nail body tip 6, and the inner nail body tip 6 is facing the center of the V-shaped groove 9; the inner nail body The body tip 6 has a thread on the outside, and is rotatably fixed in the cavity of the outer nail body 1 by a nut 5 arranged in cooperation; There are nail slots for screwdrivers. The expansion sheet 7 is a...

Embodiment 2

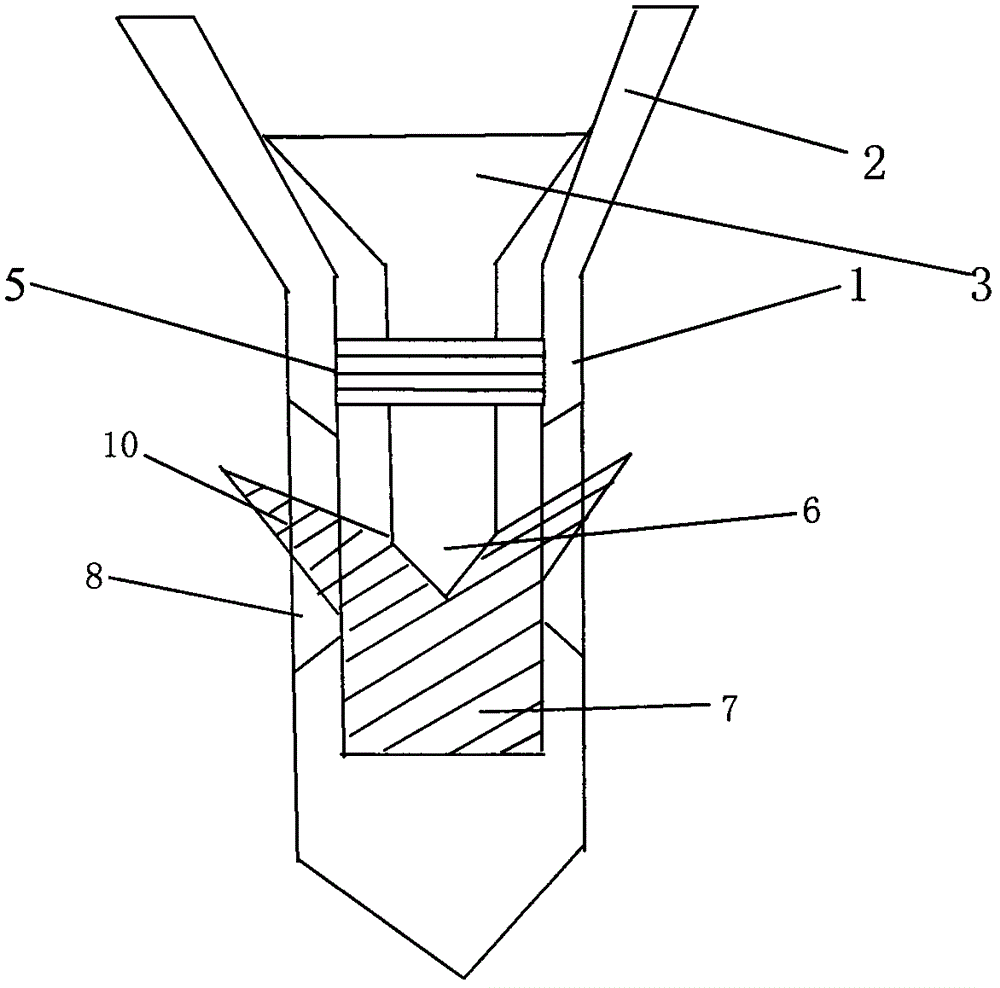

[0020] The main part of this embodiment is the same as that of Embodiment 1, the difference is that the expansion sheet 7 is a cross-shaped sheet structure; the number of the expansion grooves 8 is four, and the installation positions are evenly distributed at an angle of 90 degrees to each other.

[0021] During use, the main working process of this embodiment is the same as that of Embodiment 1. The difference is that after the V-shaped groove 9 is broken, the upper edge of the cross-shaped expansion piece 7 will form four fixed thorns 10 distributed at an angle of 90 degrees to each other, and the fixing of the outer nail body 1 is more firm. There will be no slight rotation, and the fixed object is more difficult to loosen and fall off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com