Soft rhombic monofilament artificial turf and preparation method thereof

An artificial turf, diamond-shaped technology, applied in the manufacture of rayon, conjugated synthetic polymer rayon, textiles and papermaking, etc., can solve problems such as damage to air quality, reduce maintenance costs, extend service life, and improve stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

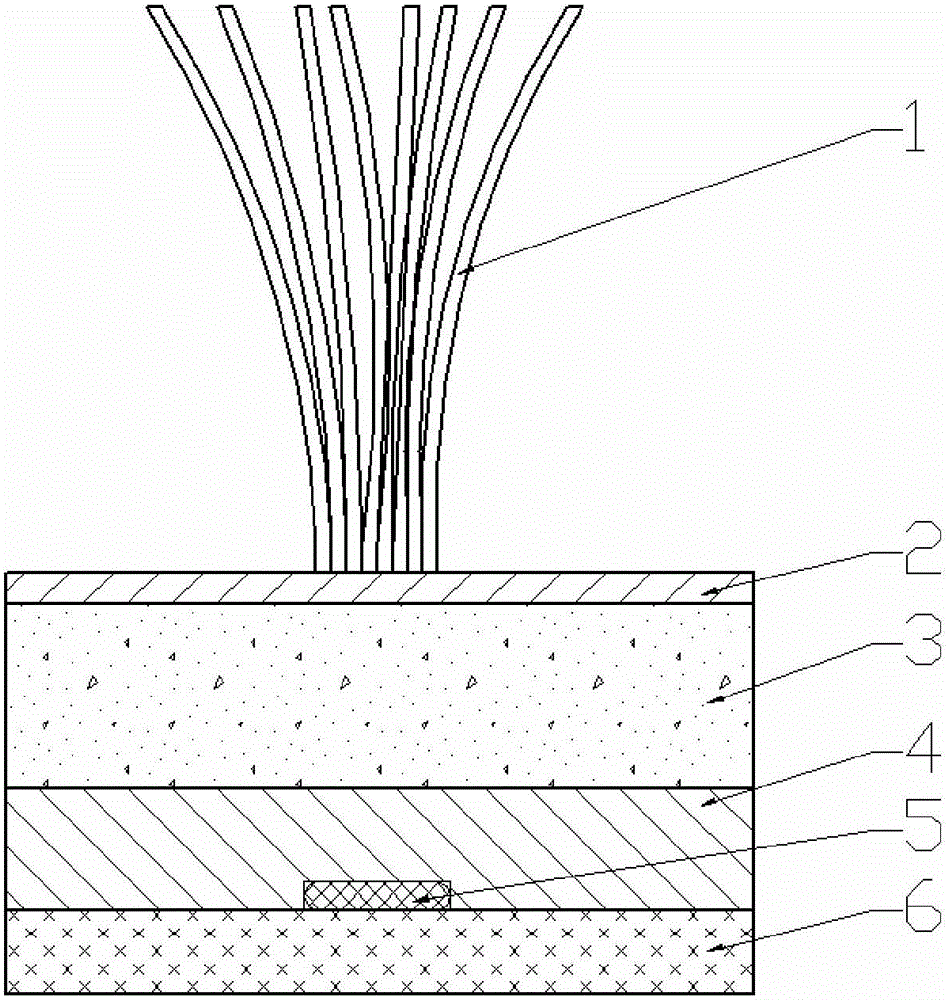

[0036] This embodiment provides a kind of pliable rhomboid monofilament artificial turf, the structure is as figure 1 As shown, it includes a diamond-shaped grass 1 with a rhombic cross-section. The diamond-shaped grass 1 is inserted into the base layer. The base layer includes a rubber layer 2. A felt layer 3 is arranged under the rubber layer 2, and a PU cushion layer is connected under the felt layer 3. 4. The lower surface of the PU cushion layer 4 is coated with an adhesive layer 6, and on the lower surface of the PU cushion layer 4, there is a pit corresponding to the insertion position of the diamond-shaped grass silk 1, and at the root of the lower end of the diamond-shaped grass silk 1 An anti-off fastening ring 5 is provided, and the anti-off fastening ring 5 is arranged at the pit.

[0037] The aforementioned felt layer 3 is an asphalt felt; the anti-off fastening ring 5 is a rubber ring.

[0038] The product of this embodiment is provided with an anti-loosening fa...

Embodiment 2

[0040] The present embodiment provides a method for preparing the adhesive layer 6 of a pliable diamond-shaped monofilament artificial turf, including the following specific steps:

[0041] (1) Weigh the raw materials according to the ratio, and the raw materials include the following components in parts by mass: 62 parts of natural rubber, 28 parts of hydroxystyrene-butadiene latex, 48 parts of tackifying resin, 6 parts of triethylhexyl phosphoric acid, Gur gum 5 parts, polyacrylate resin 13 parts, styrene-acrylic emulsion: 5 parts, epoxy acrylate: 3 parts, vinyl resin: 4.8 parts, styrene: 3.2 parts;

[0042](2) Add the above raw materials into the reaction kettle, set the temperature at 198°C, stir for 90 minutes, then add 4 parts of antioxidant, 4 parts of anti-aging agent, 1.6 parts of dispersant, 12 parts of filler oil, 9 parts of magnesium oxide, and oxidize 1 part of zinc, control the temperature at 168°C, and stir for 125 minutes;

[0043] (3) Cool down the mixed rubb...

Embodiment 3

[0045] This embodiment provides a kind of preparation method of soft rhomboid monofilament artificial turf, comprising the following steps:

[0046] (a) Send polyacrylate resin, vinyl resin, antioxidant, colorant, composite dispersant, POE elastic composite material, and methyl acrylate to the agitator at a stirring speed of 240-280r / min, and mix well to form a Mixture;

[0047] (b) Put the mixture into the extruder for extrusion and drawing. The temperature of each section of the extruder is 120°C, 160°C, 190°C, 230°C, 250°C; then go through the heat stretching box, heat treatment box, and finally wind up. Prepare artificial turf;

[0048] Wherein, the temperature of the heat stretching box is 135-145°C, and the temperature of the heat treatment box is 112-118°C;

[0049] (c) Twist the prepared artificial turf into strands, use a tufting machine to pass the turf through the rubber layer and the felt layer according to the specified row and needle distance, tuft it onto the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com