Bent RF connector housing

A technology of radio frequency connectors and shells, which is applied in the direction of connection, parts of connecting devices, electrical components, etc., can solve problems such as product corrosion, shell shedding, and irregular process operations, so as to facilitate expansion and deformation, not easy to loosen and fall off, Guarantee the effect of normal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

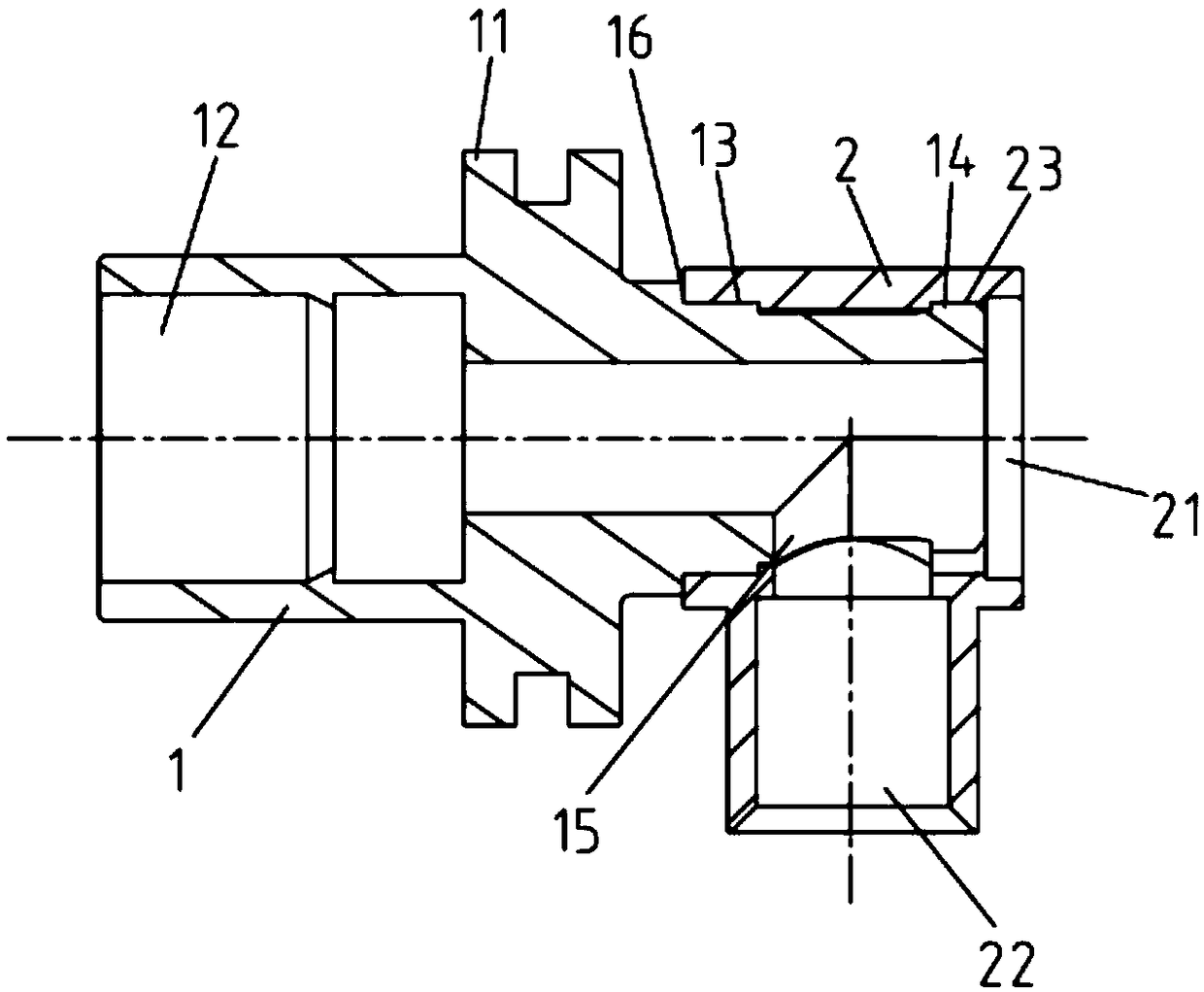

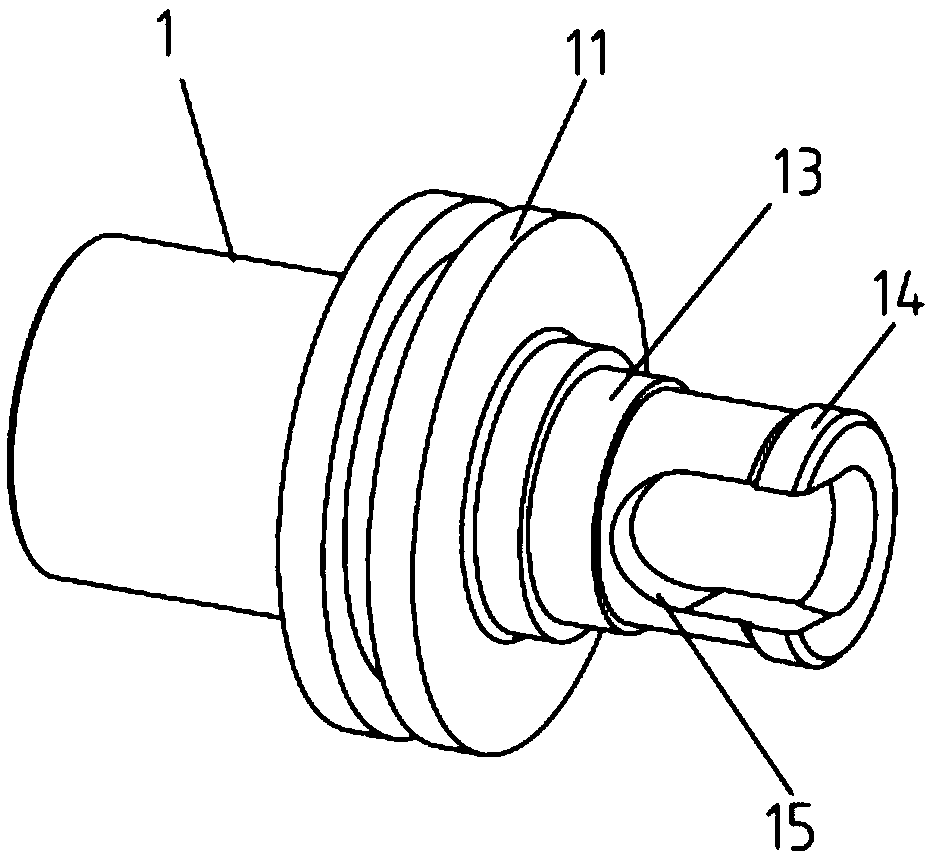

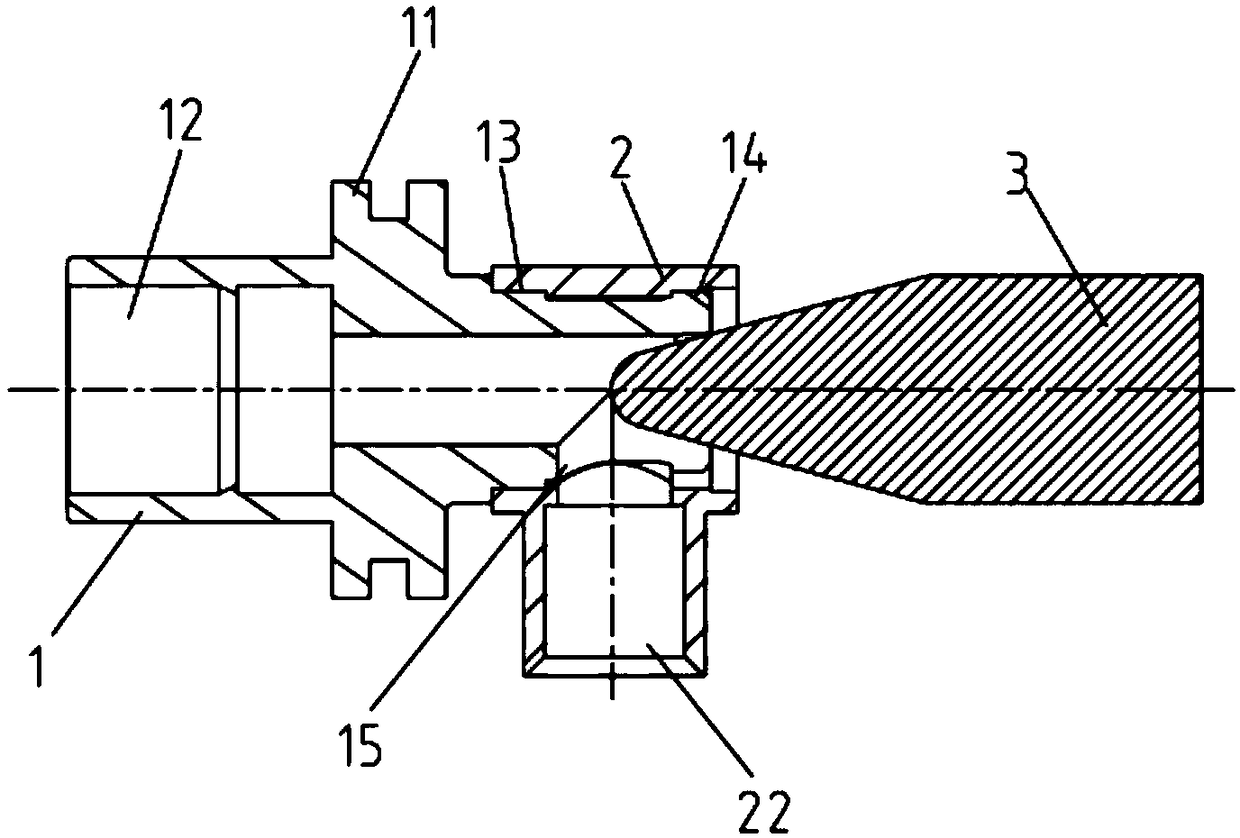

[0017] Such as figure 1 with figure 2 As shown, the present invention includes a main shell 1 and a secondary shell 2 fixed on the right end of the main shell 1 . The main housing 1 is a stepped shaft structure with a large left end and a small right end, and two anti-slip platforms 11 extend radially outward from the middle. The main housing 1 is provided with an axial through hole 12 of a stepped structure. An annular press-fit platform 13 is provided with an annular positioning platform 14 on the outside of its small end, and a U-shaped axial through groove 15 is also provided on one side of the outer peripheral surface of the small end of the main shell 1 . The sub-housing 2 is an overall structure of a cube at the upper end and a cylinder at the lower end. The sub-housing 2 is provided with an upper horizontal through-hole 21 and a lower-end vertical through-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com