An engine performance detection and comparison device

A comparison device and engine technology, which is applied in the direction of engine testing, measuring equipment, machine/structural component testing, etc., can solve problems such as errors and power consumption, and achieve the effect of reasonable structure, small assembly length and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

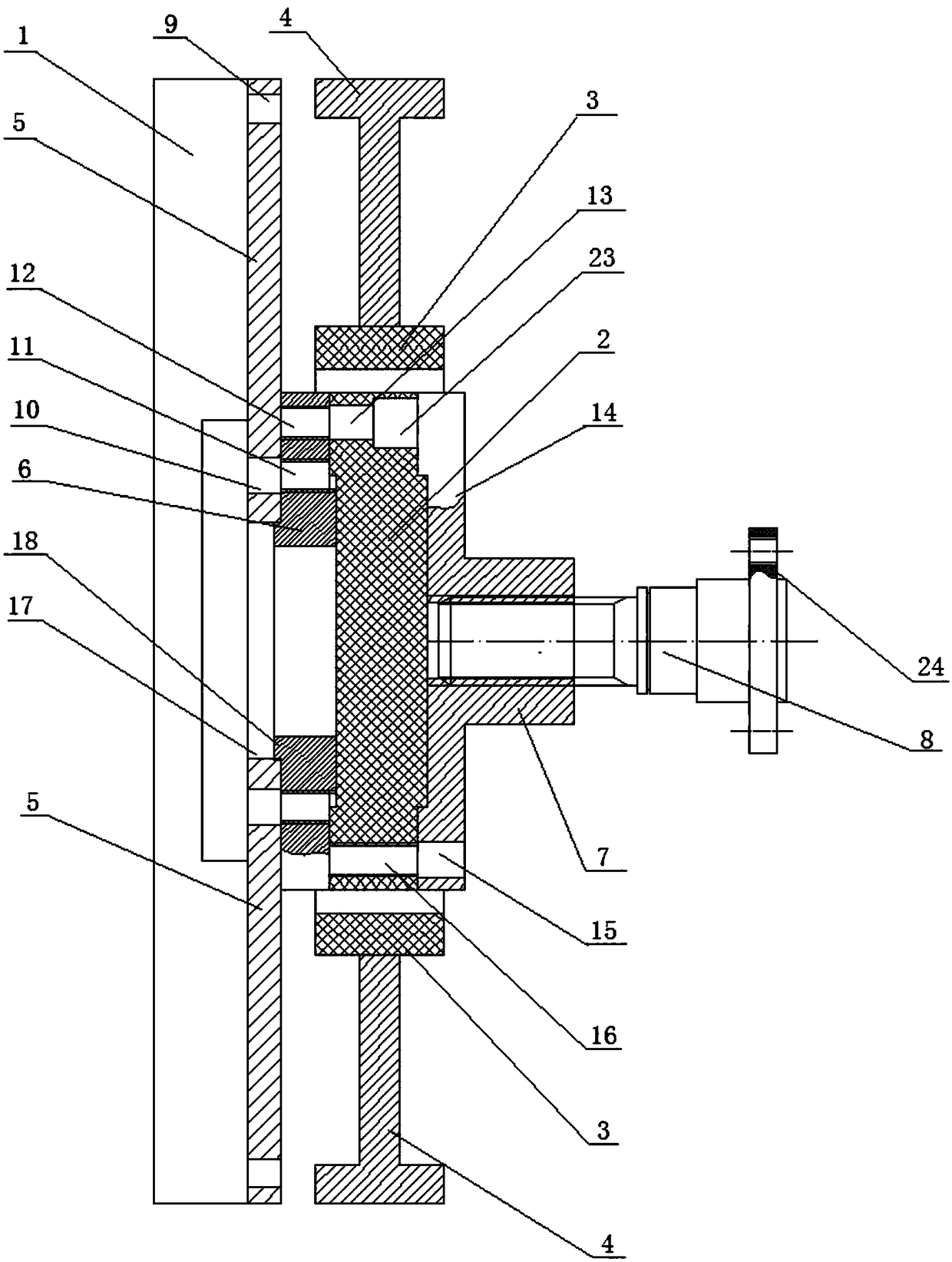

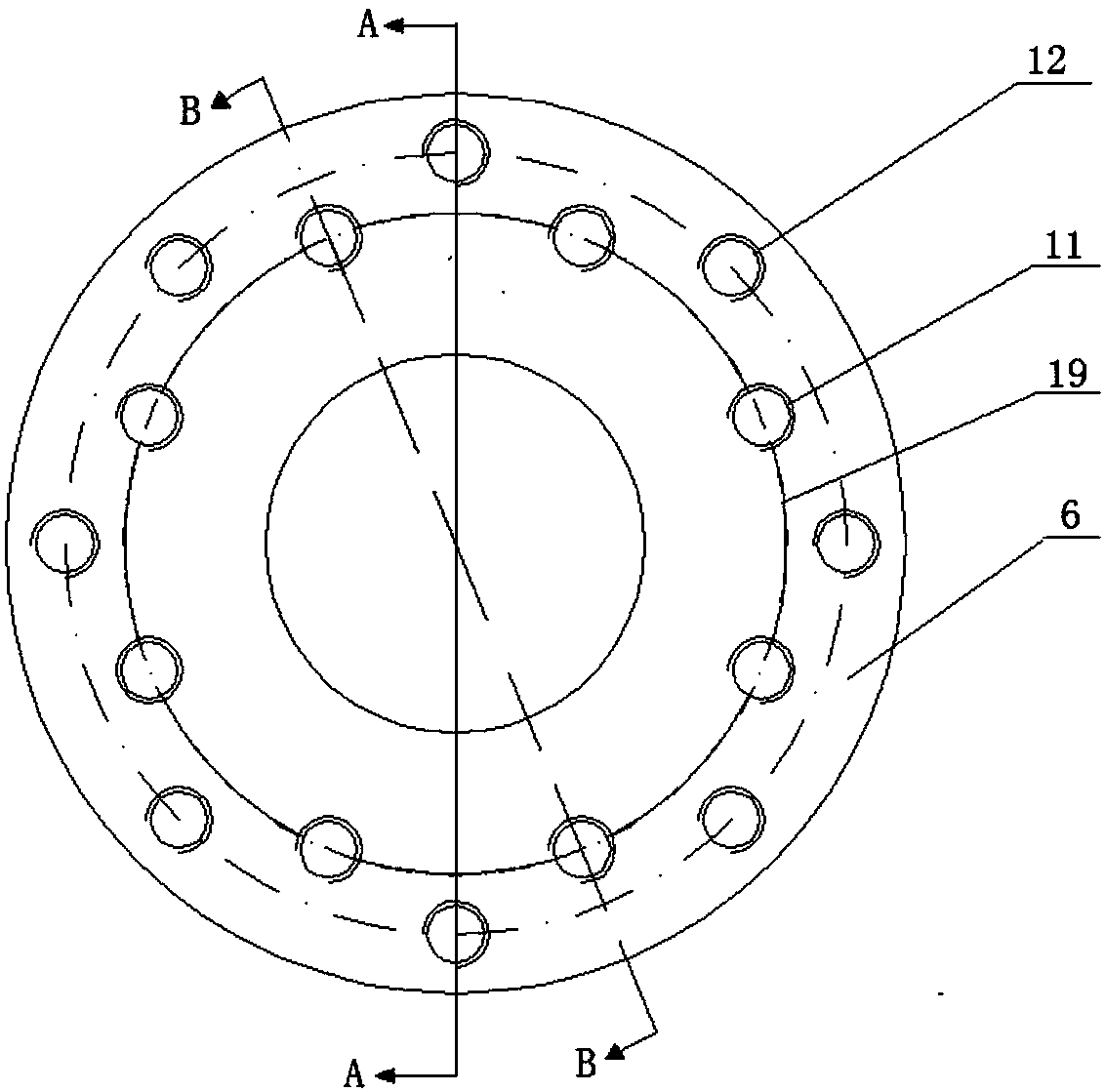

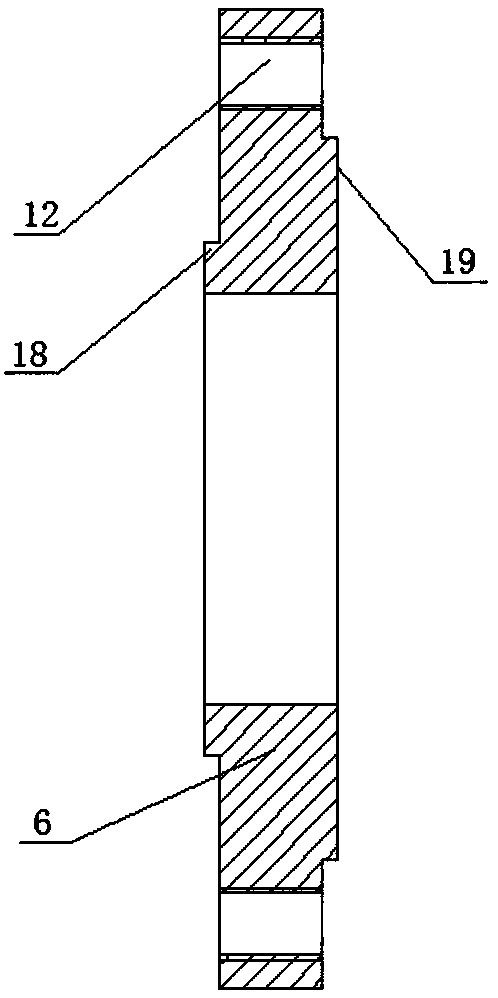

[0026] The specific embodiment of the present invention is like this: with reference to Figure 1-Figure 8 As shown, an engine performance detection and comparison device includes a connecting assembly that is coaxially connected with the flywheel 1 and outputs torque to the outside. A sensor 2 that can transmit torque is coaxially installed on the connecting assembly. The matching processing device is coaxially installed on the outside of the sensor 2 with a drive shaft assembly that can be connected to the load. Connected to drive the load to rotate, the sensor 2 can detect the received torque, speed and other parameters, through the processing device for data analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com