Automatic component inserter for PCB

An automatic plug-in machine and PCB board technology, applied in the field of automation, can solve problems such as affecting work efficiency, increasing production costs, and easy tilting or falling off of electronic components, achieving the effect of improving aesthetics and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

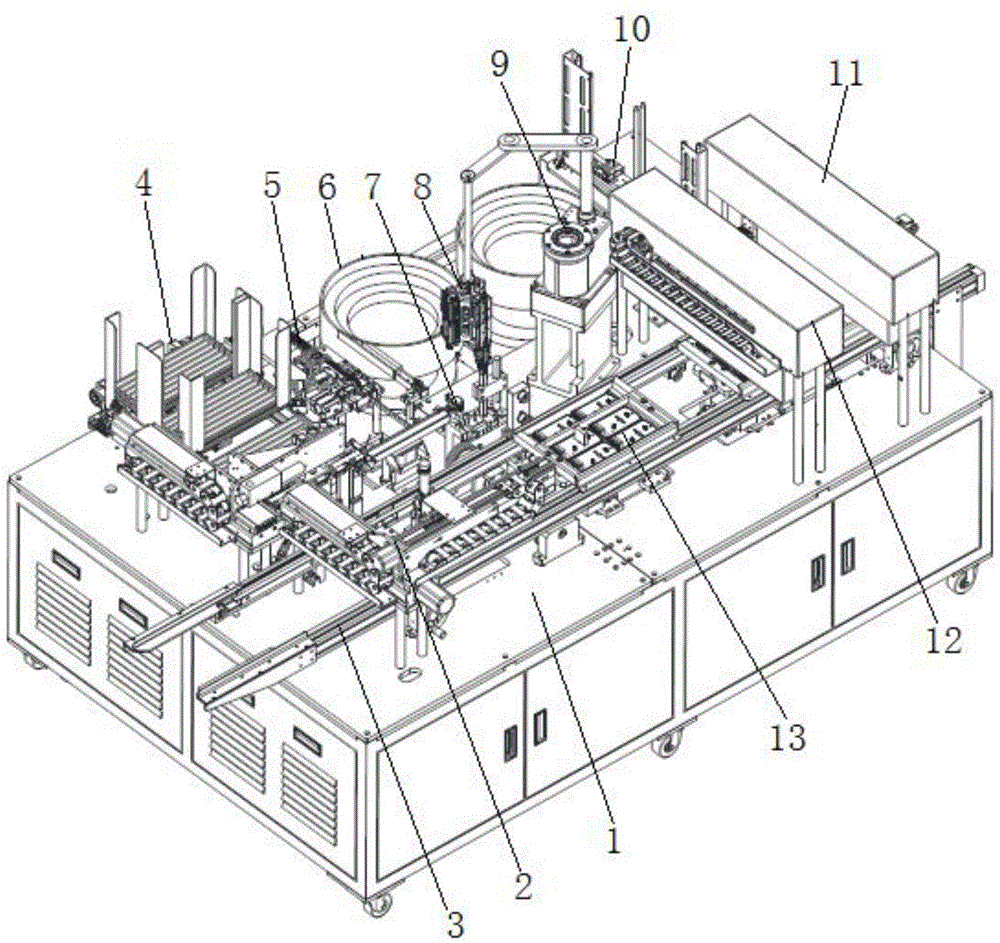

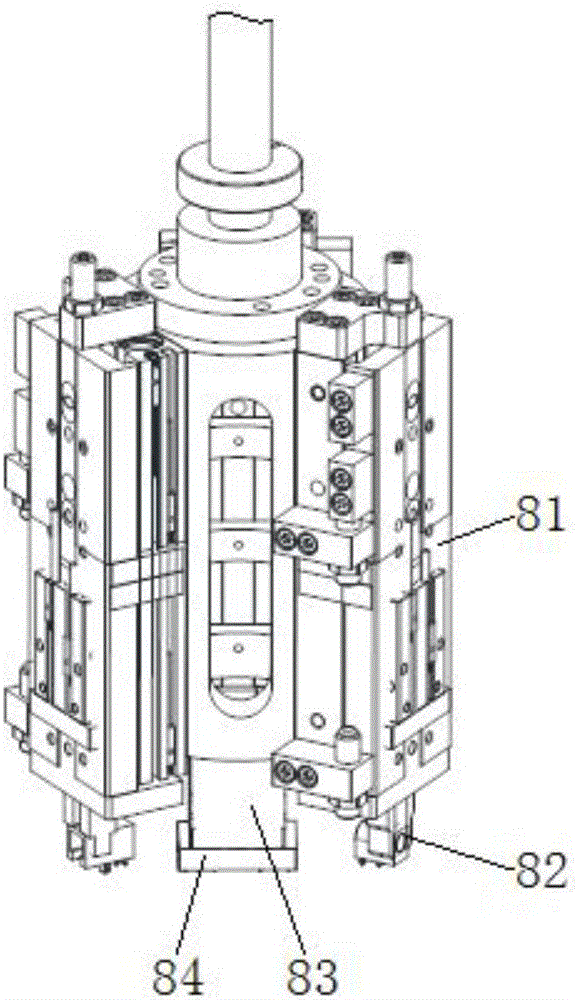

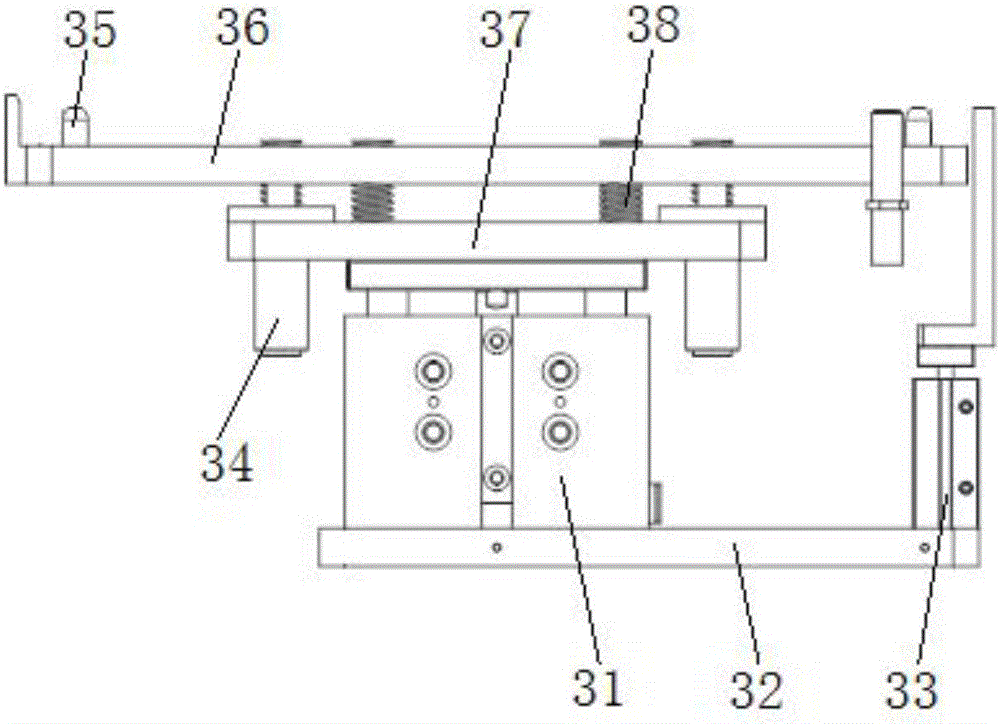

[0026] attached figure 1 It is the PCB board automatic plug-in machine according to the present invention, comprising a machine base 1, a PCB board conveying mechanism respectively arranged on the machine base 1, a mechanical arm 9, a manipulator 11, a component feeding mechanism, and a component pin for detecting Whether the detection mechanism 7 of damage and inclination, the dispenser 2, the component positioning mechanism 12, the controller (not shown) that controls the action of the above-mentioned mechanism; Before inserting electronic components, put a layer of glue on the socket of the PCB board, so that the components will not fall off after sticking to the PCB board, and reduce the defective rate; the component positioning mechanism 12 is set on the PCB board conveying mechanism The discharge end plays the role of fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com