Control system for hybrid vehicle

A technology of hybrid electric vehicle and control system, which is applied to the layout of multiple different prime movers of hybrid electric vehicles and general power plants, and traction driven by engines, etc., which can solve problems such as insufficient driving force and driver discomfort, and achieve Effect to prevent decline of driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

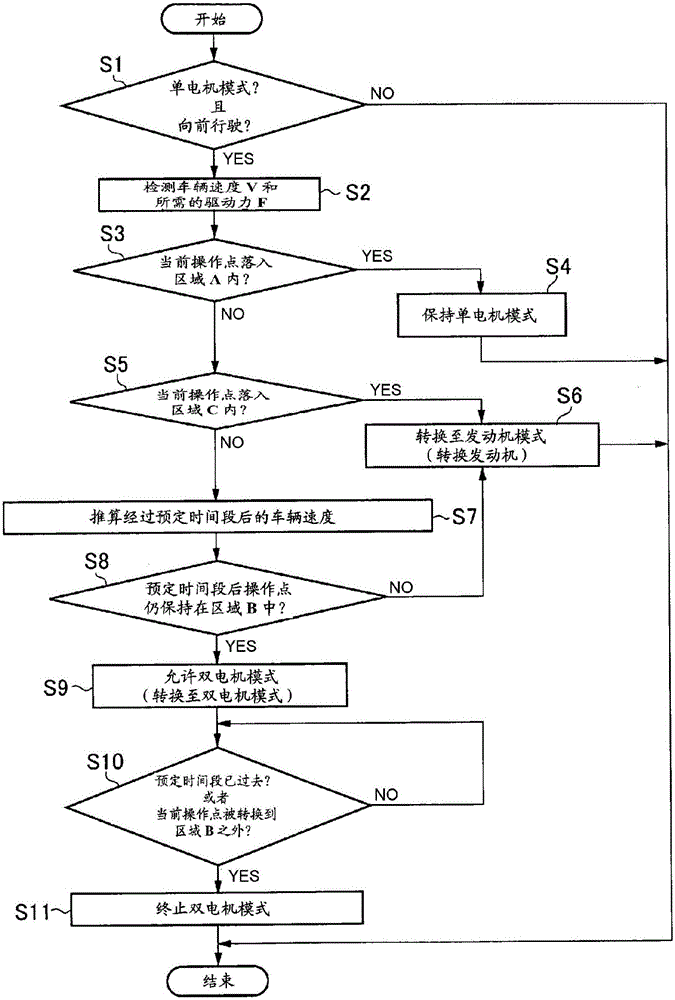

Method used

Image

Examples

Embodiment Construction

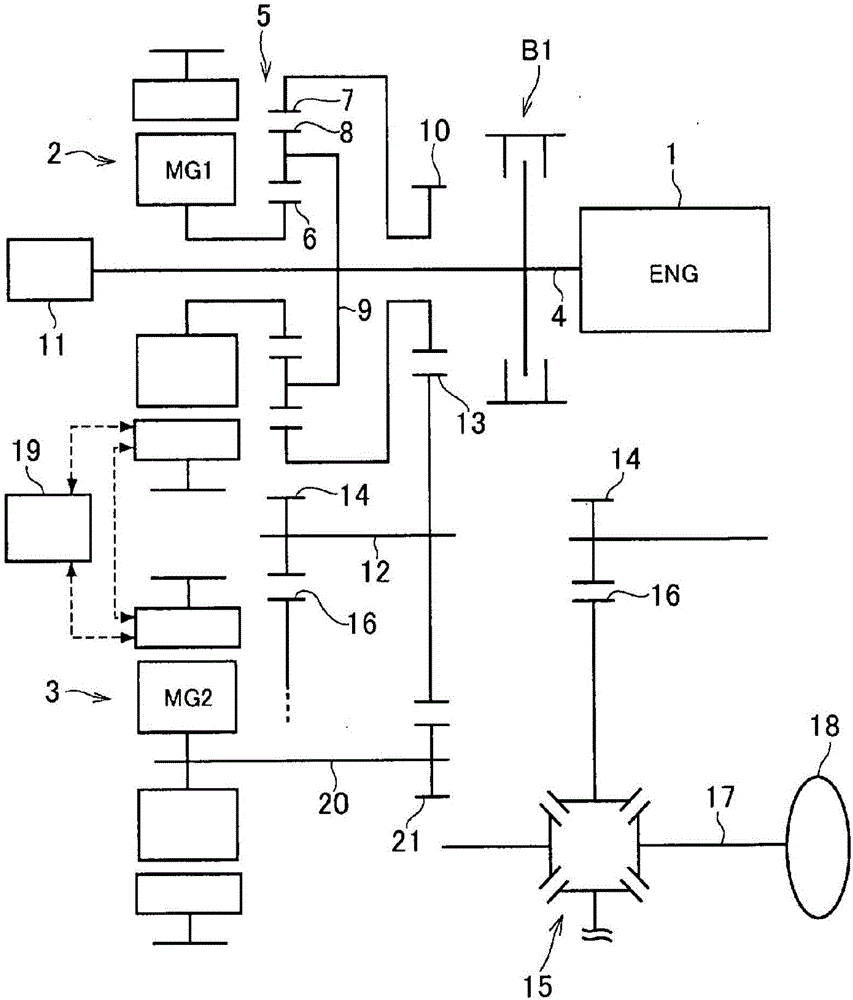

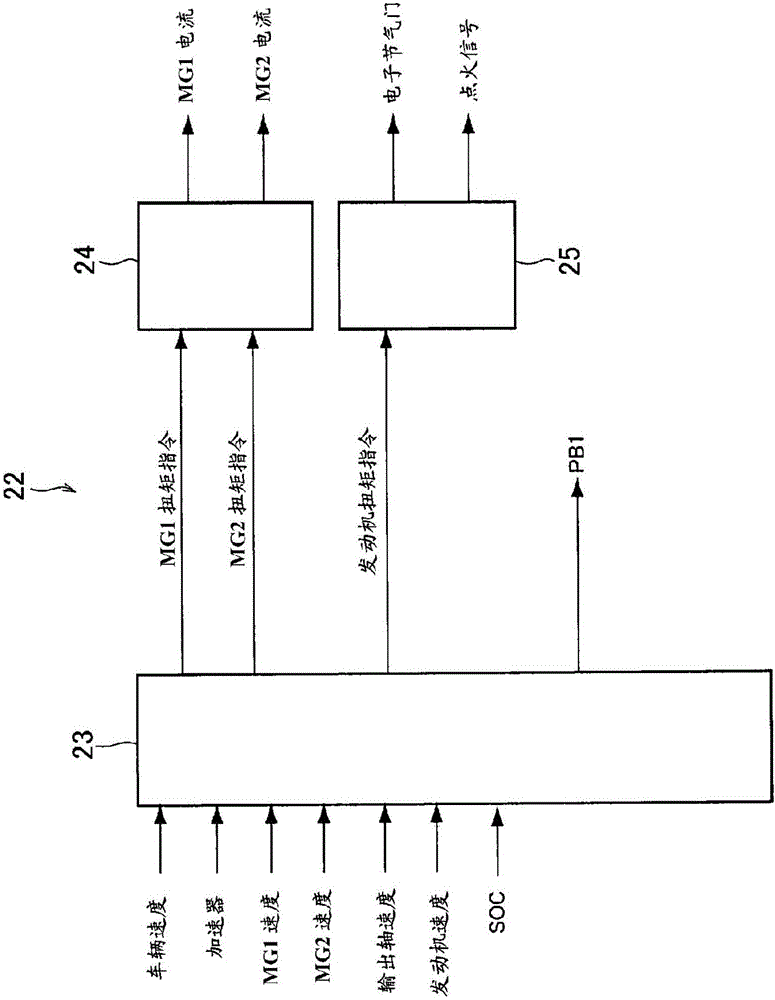

[0030] now refer to figure 2 , shows a first example of a hybrid vehicle to which the control system of the preferred example is applied. figure 2 The illustrated hybrid vehicle includes a prime mover comprising an engine 1 (in figure 2 referred to as "ENG") and the first motor / generator 2 and the second motor / generator 3 (in figure 2 referred to as "MG1" and "MG2"). A hybrid vehicle can operate in an appropriate operating mode selected from an engine mode, a dual-motor mode, and a single-motor mode, in which the vehicle is powered by the engine 1; in a dual-motor mode, the vehicle is powered by the first motor / generator 2 and the second motor / generator 3, while the engine 1 is stopped; in single motor mode, the vehicle is powered by either the first motor / generator 2 and the second motor / generator 3, while the engine 1 stop.

[0031]An output shaft 4 of the engine 1 is connected to a power split device 5 . The power distribution device 5 is a single-pinion type plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com