Printing control method and device

A printing control and equipment technology, applied in printing devices, printing, etc., can solve problems such as time-consuming, laborious, and paper waste, and achieve the effect of ensuring printing quality and improving adjustment processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

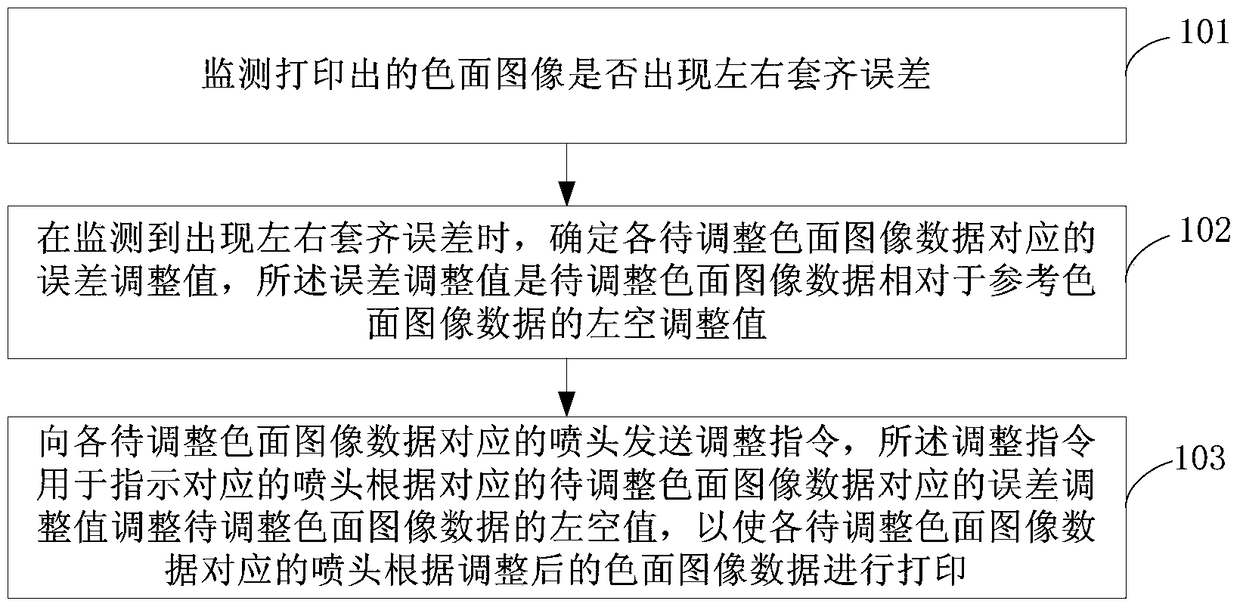

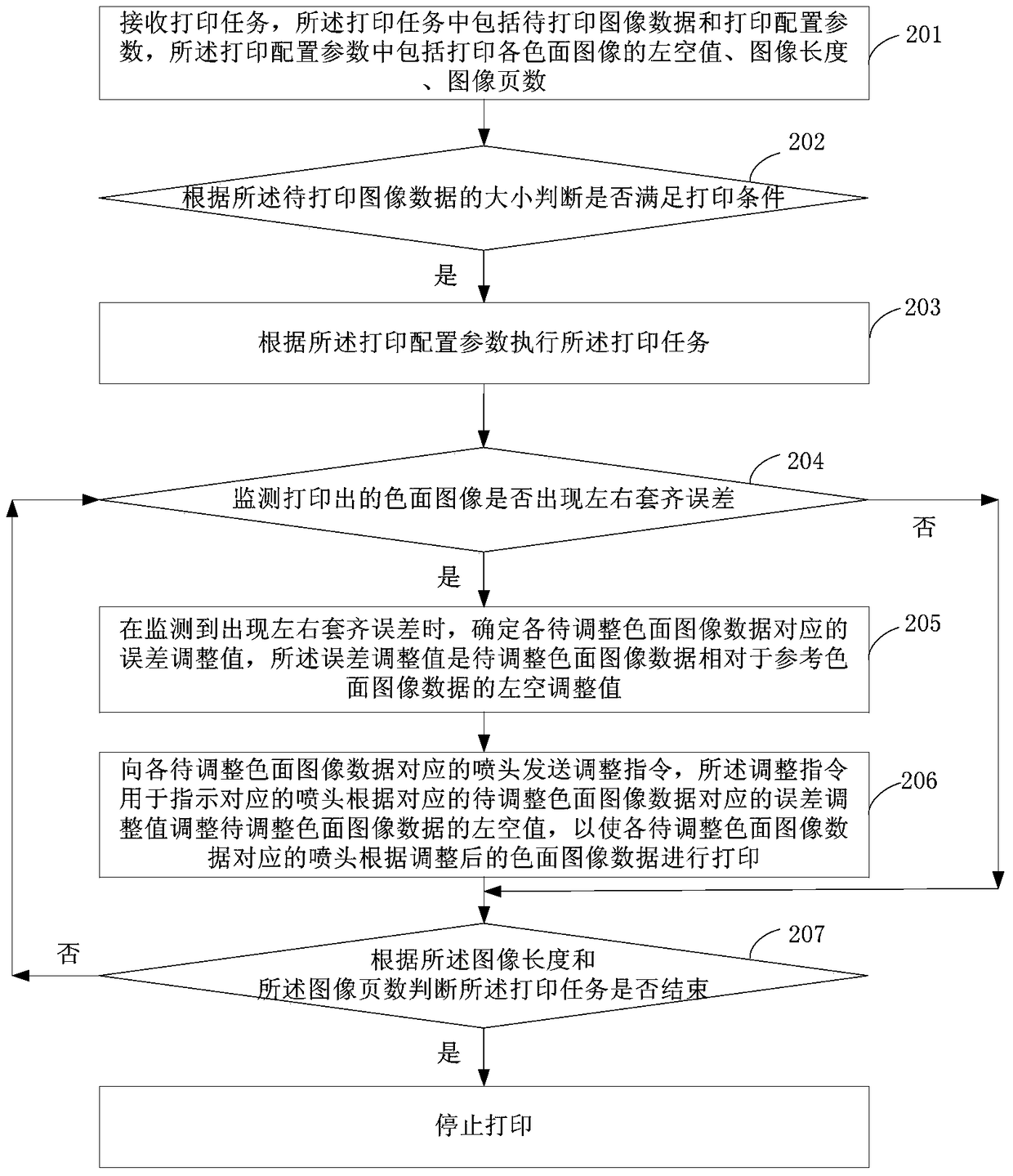

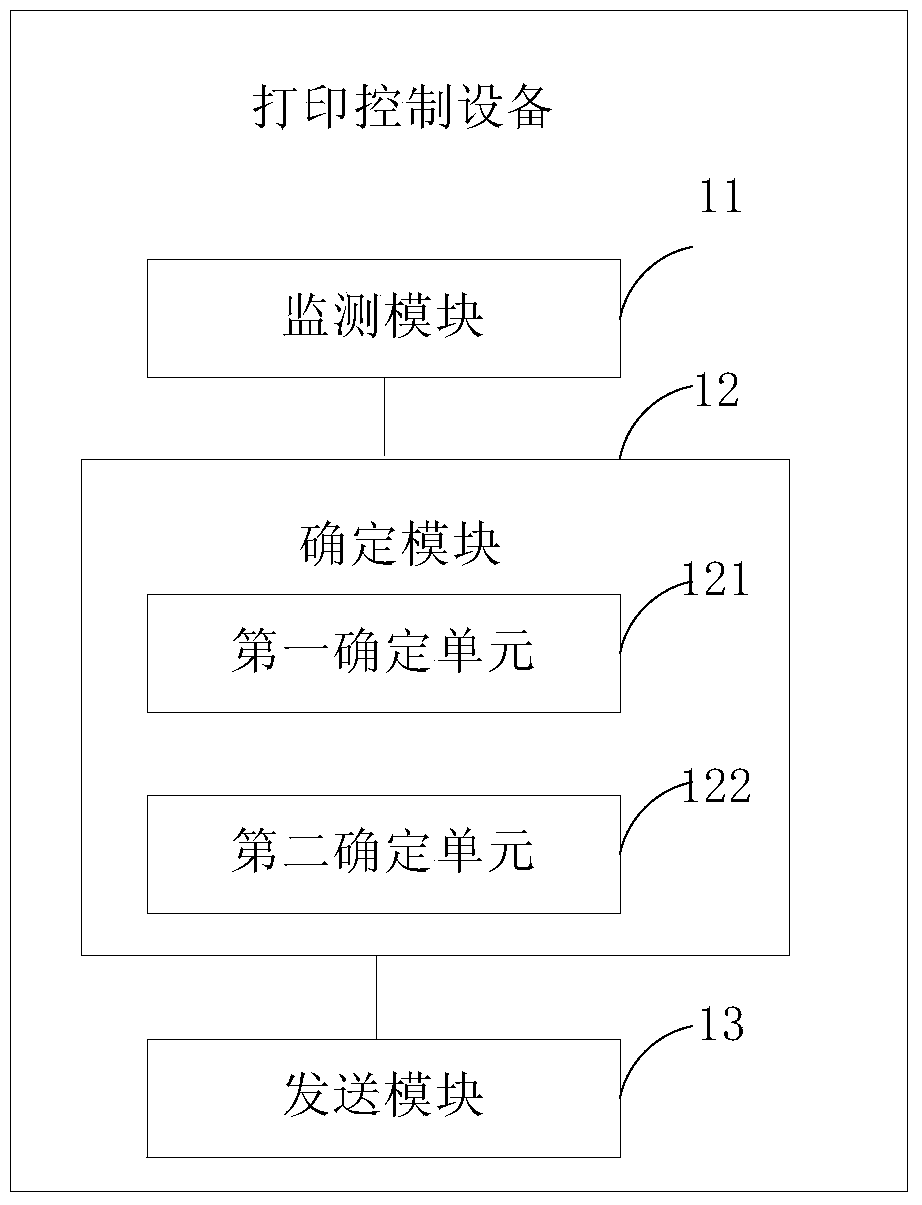

[0019] figure 1 It is a flow chart of Embodiment 1 of the printing control method of the present invention. In this embodiment, the printing control method is executed by a printing control device. The printing control device may be a digital printing device, such as figure 1 As shown, the printing control method includes the following steps:

[0020] Step 101 , monitoring whether there is a left-right alignment error in the printed color surface image.

[0021] Step 102. When the left-right registration error is detected, determine the error adjustment value corresponding to each color plane image data to be adjusted, and the error adjustment value is the left-space adjustment of the color plane image data to be adjusted relative to the reference color plane image data value.

[0022] Step 103: Send adjustment instructions to the nozzles corresponding to the color surface image data to be adjusted, the adjustment instructions are used to instruct the corresponding nozzles t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com