Rear-cutter trimming device of sewing machine

A technology of sewing machine and cutting knife, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., which can solve the problems of unfavorable work efficiency and improvement, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

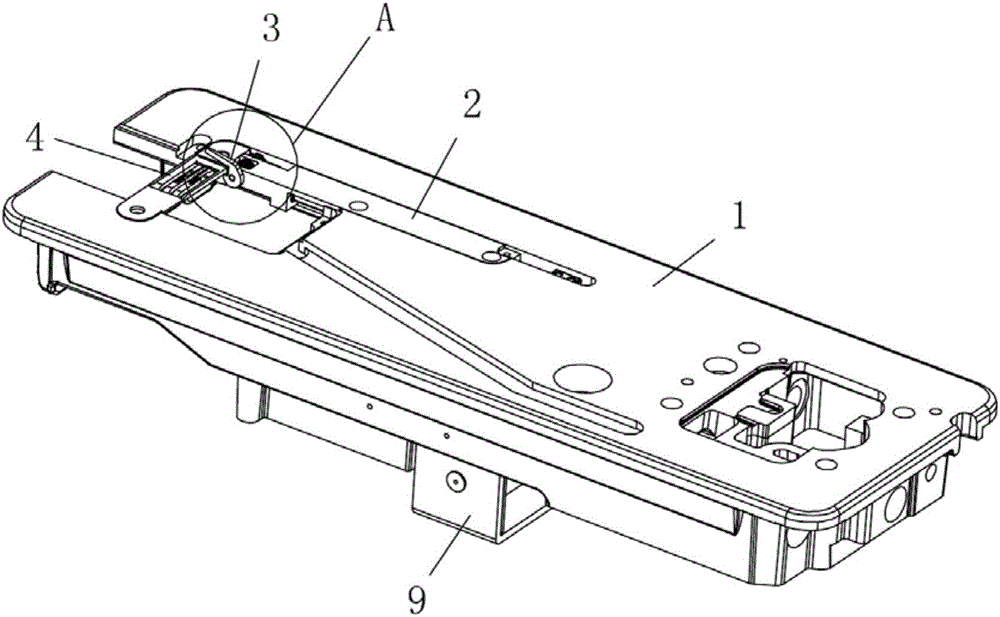

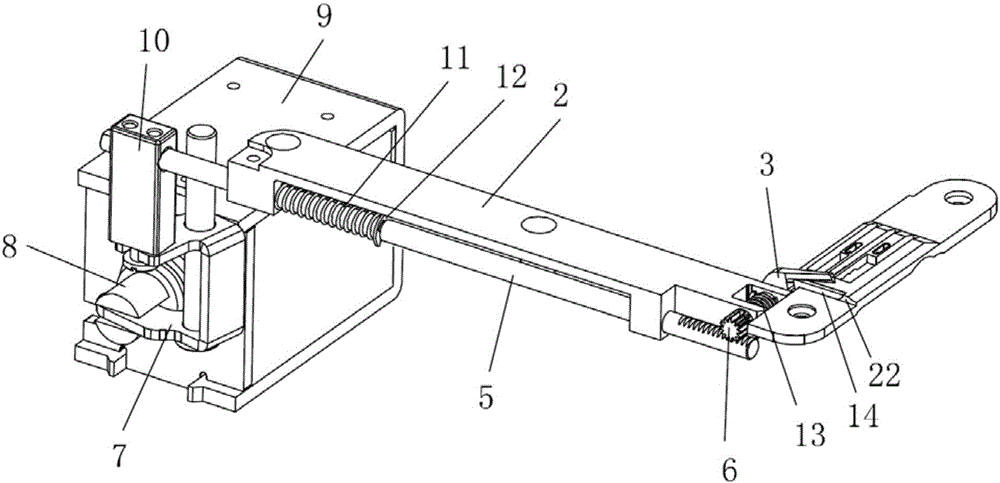

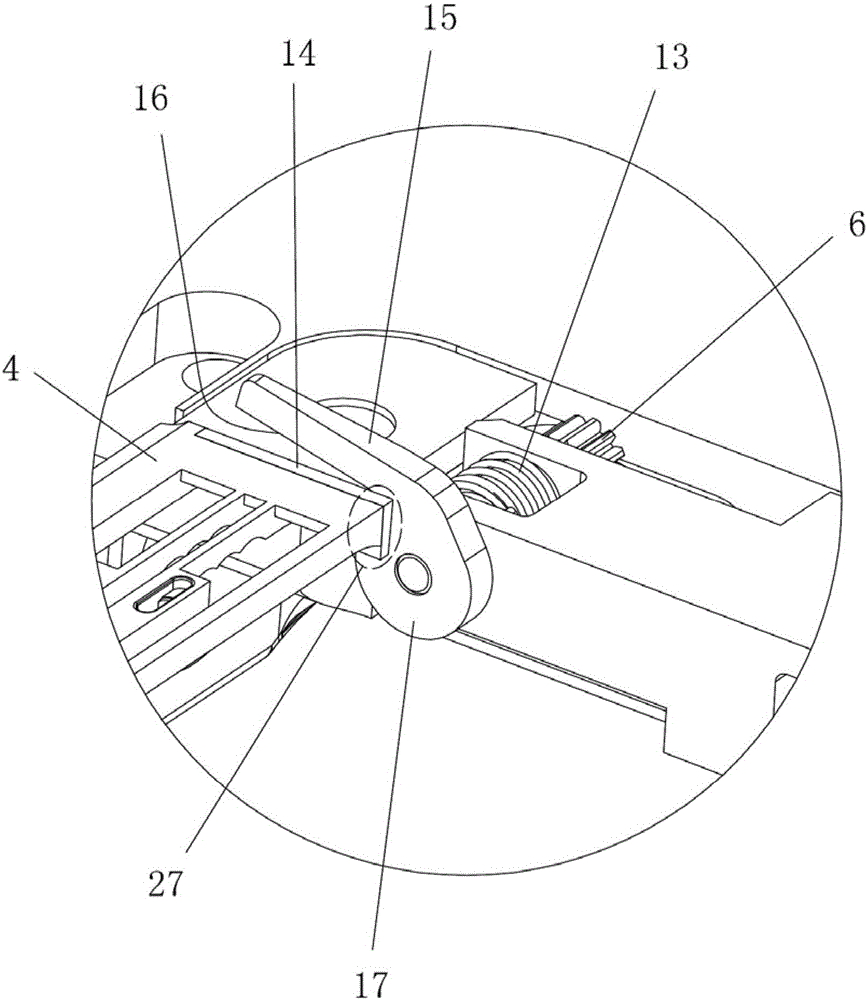

[0029] Embodiment 1: the rear cutter thread trimming device of the sewing machine, a thread trimming step 22 is provided on the frame 1 at the rear part of the needle plate 4, and a fixed knife 14 is installed on the side wall of the thread trimming step 22, and the thread trimming step 1 The side frame is rotatably equipped with a tool bar 6, on which a moving knife 3 is installed, and the moving knife 3 is close to the fixed knife 14; the lower side of the frame is provided with a driving mechanism for driving the tool bar to rotate.

[0030] The thread trimming step 22 is provided on the needle plate 4 .

[0031] Described frame 1 is provided with a cross bar 5, and the frame of cross bar 5 rear ends is provided with driving mechanism, and driving mechanism drives described cross bar 5 to do lateral reciprocating motion, and the front end of cross bar 5 is provided with rack portion 25, and tooth The bar portion is engaged with the end teeth on the rear portion of the cutte...

Embodiment 2

[0037] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that a thread trimming groove 23 is designed on the needle plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com