Single-pole attachment fabricated mooring structure for offshore wind turbine foundation and construction method of single-pole attachment fabricated mooring structure

An offshore fan and assembly technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of increasing the berthing difficulty of operation and maintenance ships, small berthing space, inconvenient replacement and maintenance, etc., to achieve convenience The effects of ship berthing and operation and maintenance operations, increased strength and stability, and easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

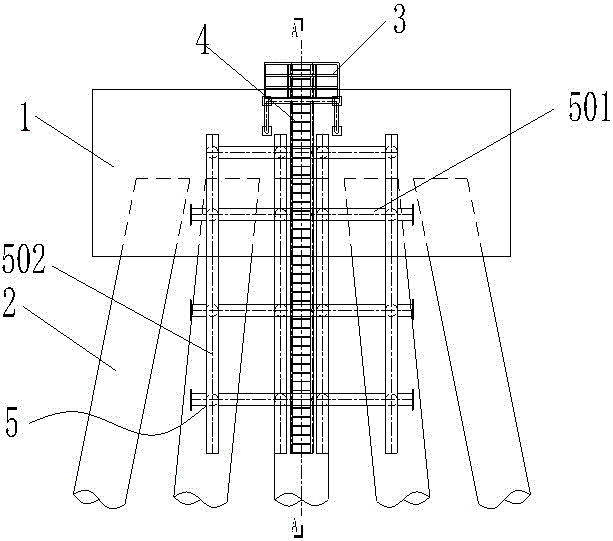

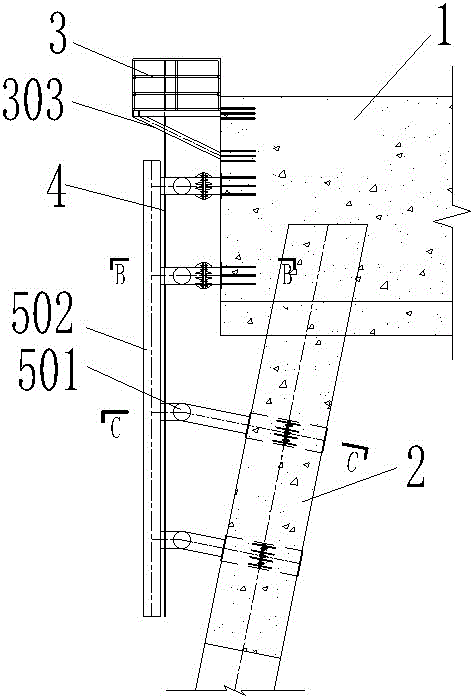

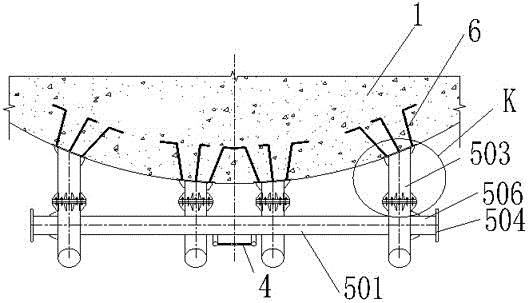

[0031] The offshore wind turbine foundation single-column attachment assembled berthing structure of the present invention includes a concrete cap 1 and several steel pipe piles 2 whose upper ends are obliquely inserted into the concrete cap 1, and the upper side wall of the concrete cap 1 is provided with a steel platform 3 and the vertical steel ladder 4 pierced on the steel platform on the upper part, the concrete cap 1 and the steel pipe pile 2 are provided with a vertical berth member 5, and the berth member 5 includes several interconnected horizontal The steel pipes 501 for berthing and several steel pipes 502 for berthing are arranged vertically. The vertical steel ladder 4 is fixed on the side of the steel pipes 501 for berthing horizontally, and the bollard 506 is fixed on the side of the steel pipes 502 for berthing vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com