Ceramic valve element with drinking water control function

A ceramic spool and functional technology, applied in the direction of valve devices, multi-way valves, mechanical equipment, etc., can solve the problems of faucet structure complexity, inconvenient use process, high cost of use, and achieve low cost, avoid pollution, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

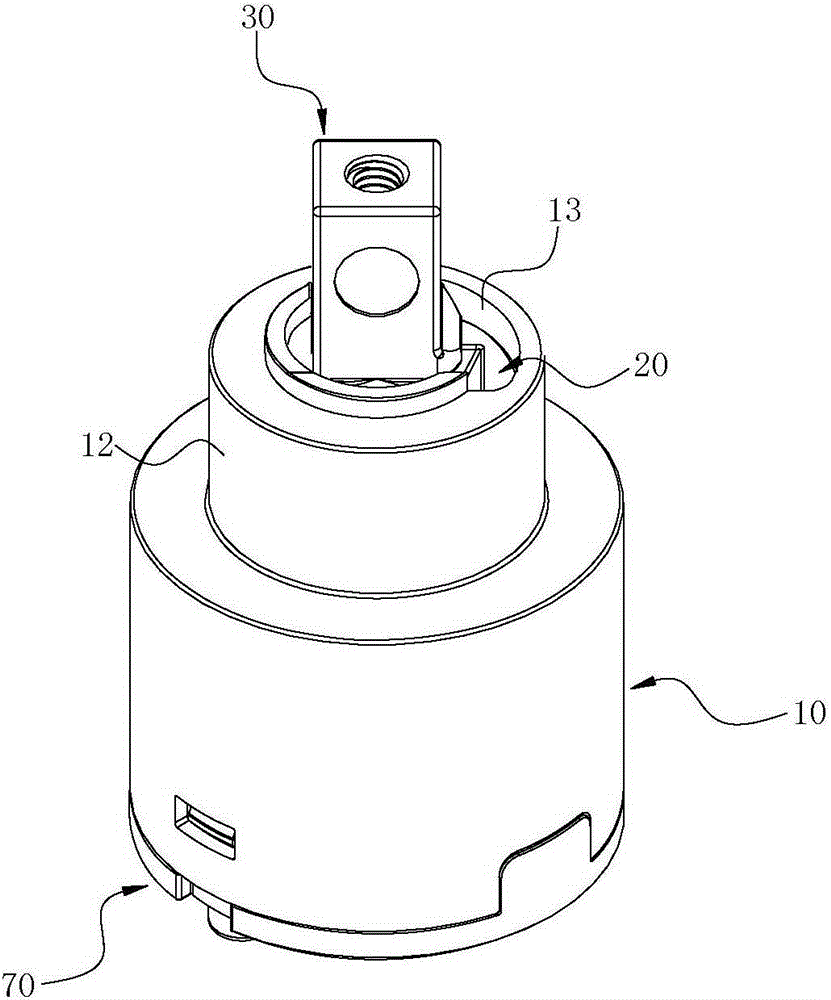

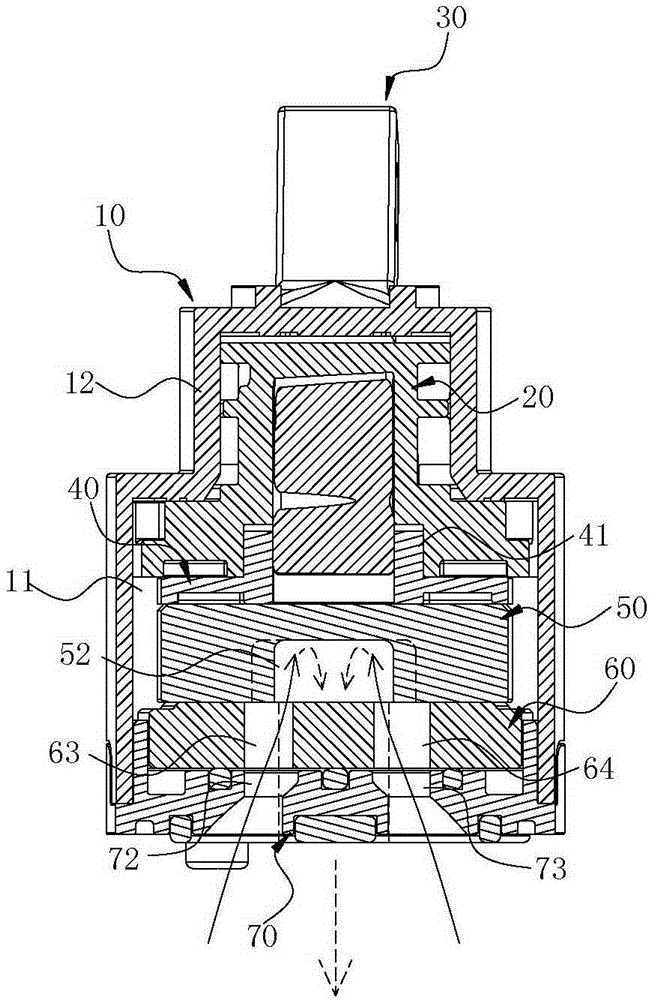

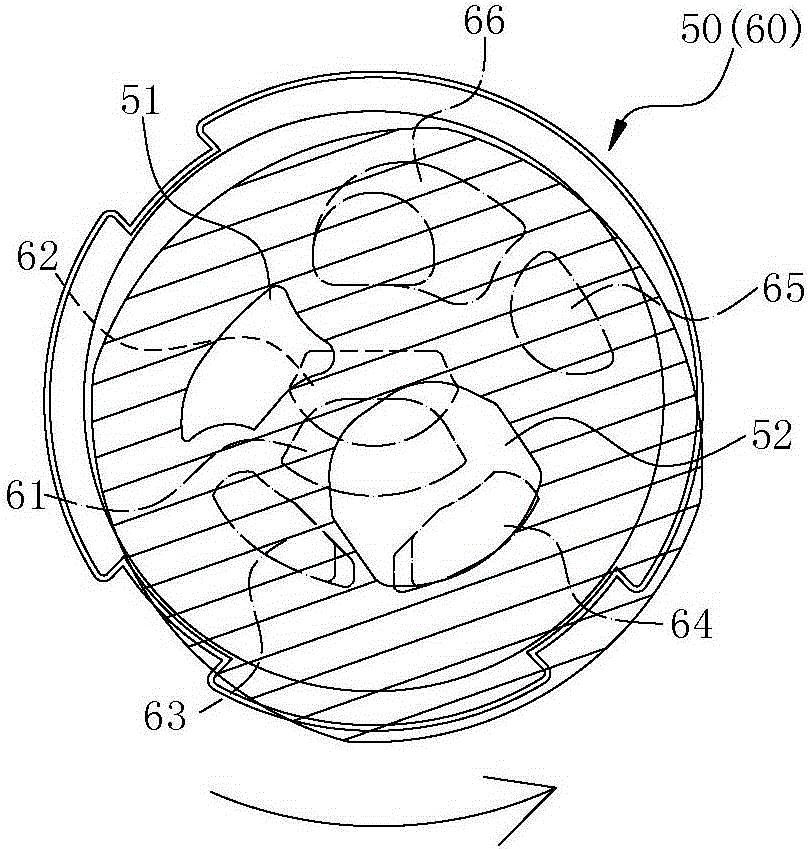

[0051] Usually according to the present invention, please firstly by Figure 1 to Figure 6As shown, the ceramic valve core of the present invention is provided with a rotating seat 20 in a valve casing 10, and a connecting block 40, a movable valve plate 50 and a fixed valve plate 50 are arranged in sequence below the rotating seat 20. The valve plate 60 and the rotating seat 20 have a valve stem 30 protruding upward from the valve housing 10 in the central group. The valve plate 50 will be able to drive the movable valve plate 50 to translate or rotate through the linkage block 40 through the operation of the valve stem 30, so as to use the change of the alignment relationship be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com