Miniature probe illuminometer

An illuminance meter and lens technology, applied in the field of illuminance measurement devices, can solve the problems of complex structure, the size of the illuminance probe cannot be placed in a narrow space, and the demand for illuminance measurement cannot be directly performed, etc., and achieves the effect of miniaturization and compact mechanical structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

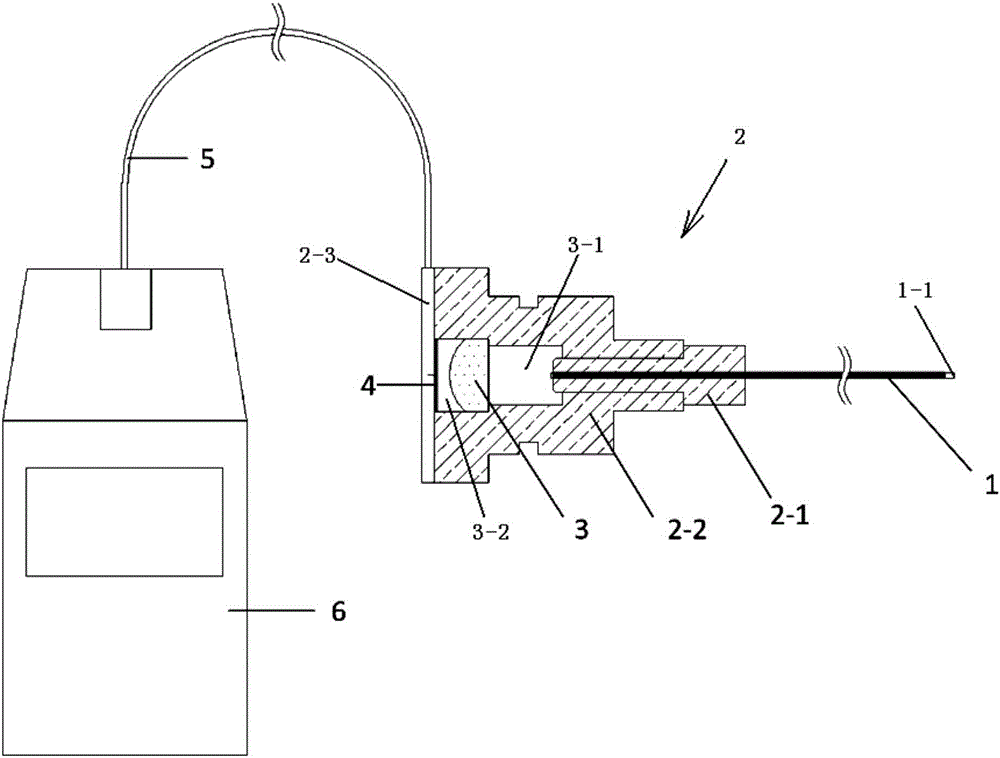

[0024] Such as figure 1 shown. The invention discloses a micro-probe illuminance meter. The micro-probe illuminance meter sequentially includes an optical fiber 1, a lens 3 and a photoelectric sensor 4 according to the optical signal transmission path;

[0025] The optical fiber 1 , the lens 3 and the photoelectric sensor 4 are axially and sequentially fixed inside the fixing assembly 2 according to the optical signal transmission path. The lens 3 is used to diverge the light guided by the optical fiber into parallel light.

[0026] The fixing assembly 2 sequentially includes a first sleeve 2-1, a second sleeve 2-2 and a sealing end cap 2-3; socket connection;

[0027] The second sleeve 2-2 sequentially includes an isolation cavity 3-1 and a lens cavity 3-2 according to the optical signal transmission path; the end of the optical fiber 1 is placed and fixed in the first sleeve 2-1;

[0028] The lens 3 is placed and fixed in the lens chamber 3-2 of the second sleeve 2-2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com