Shift performance rack test fixture

A technology for bench testing and shifting performance, applied in the field of gearbox testing, can solve the problems of inability to test abnormal vibration of gearboxes and insufficient testing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

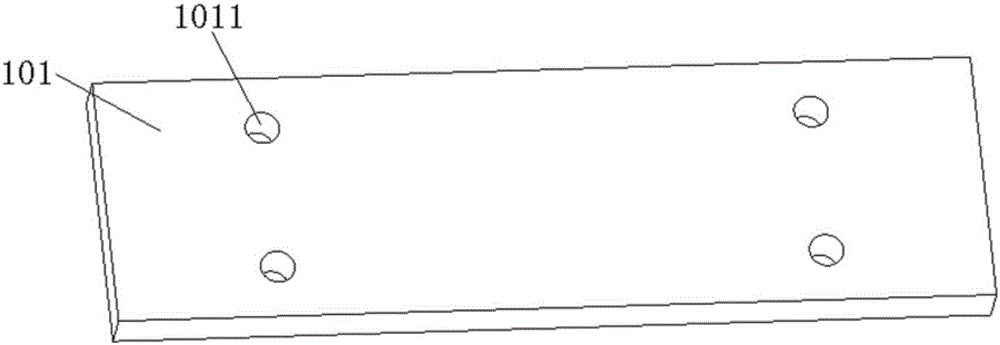

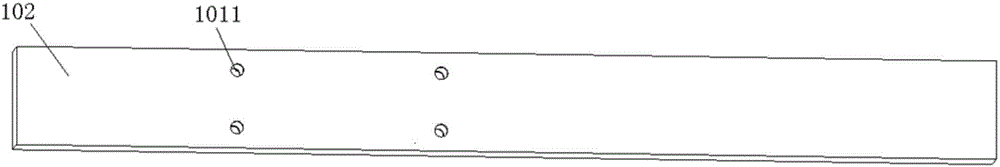

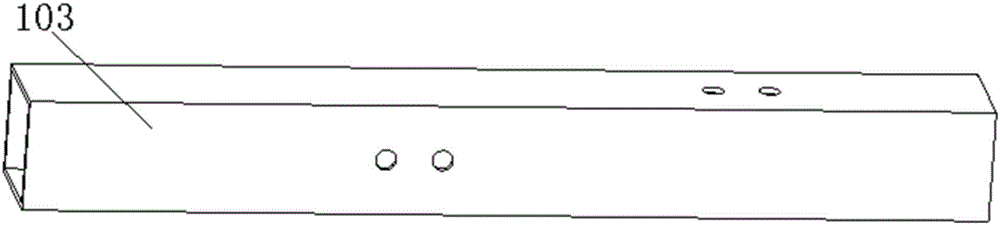

[0100] This application provides a shift performance bench test tooling, such as Figure 1 to Figure 44 As shown, including tooling bracket assembly 1, engine mount support plate 2, engine mount 3, gearbox upper mount support plate 4, gearbox upper mount 5, gearbox lower mount support assembly 6, gearbox Lower mount 7, dual-mass flywheel 22, dual-mass flywheel flange, high-speed half shaft 9, input motor 23, mount connection plate assembly 14, left half shaft 17, right half shaft 18, left output motor 24 And the output motor 25 on the right side.

[0101] The engine suspension support plate 2 , the gearbox upper suspension support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com