A device for installing and adjusting extreme ultraviolet reflective lenses

A lens and adjustment technology, applied in the field of extreme ultraviolet lithography, can solve the problems of increasing pumping speed loss, increasing pumping time, increasing pumping air resistance, etc., and achieves the effect of isolating the impact of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

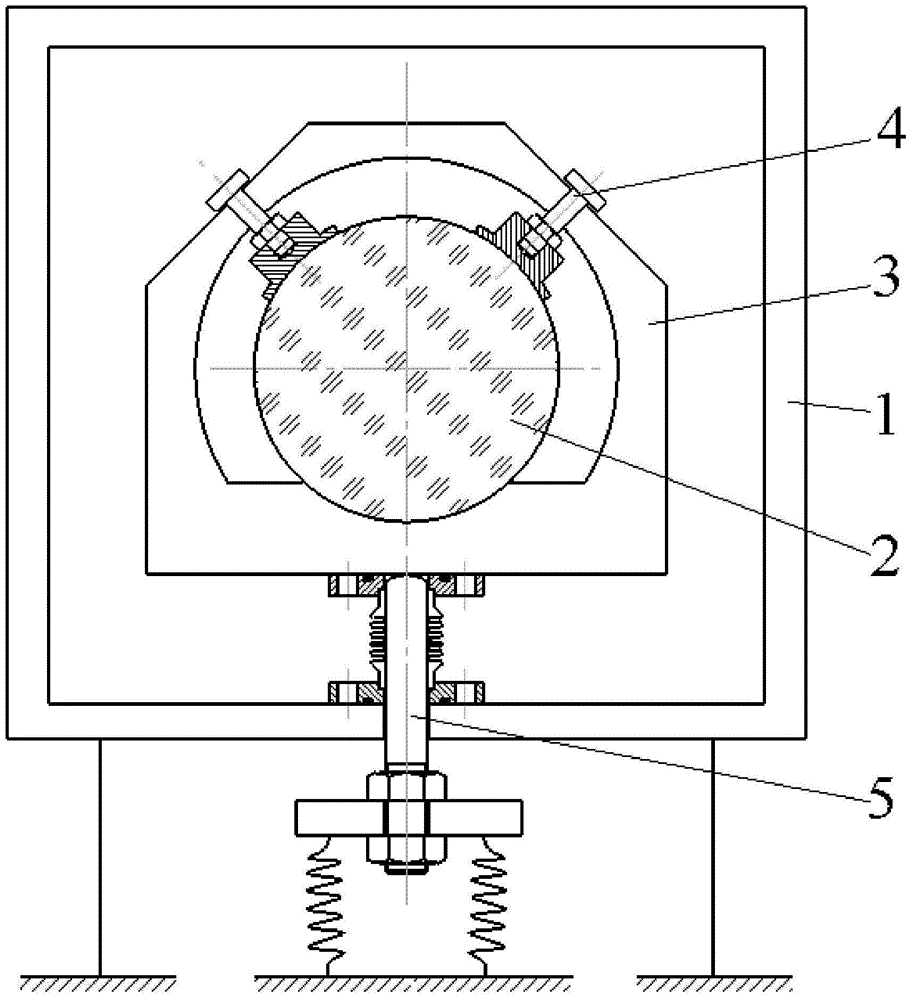

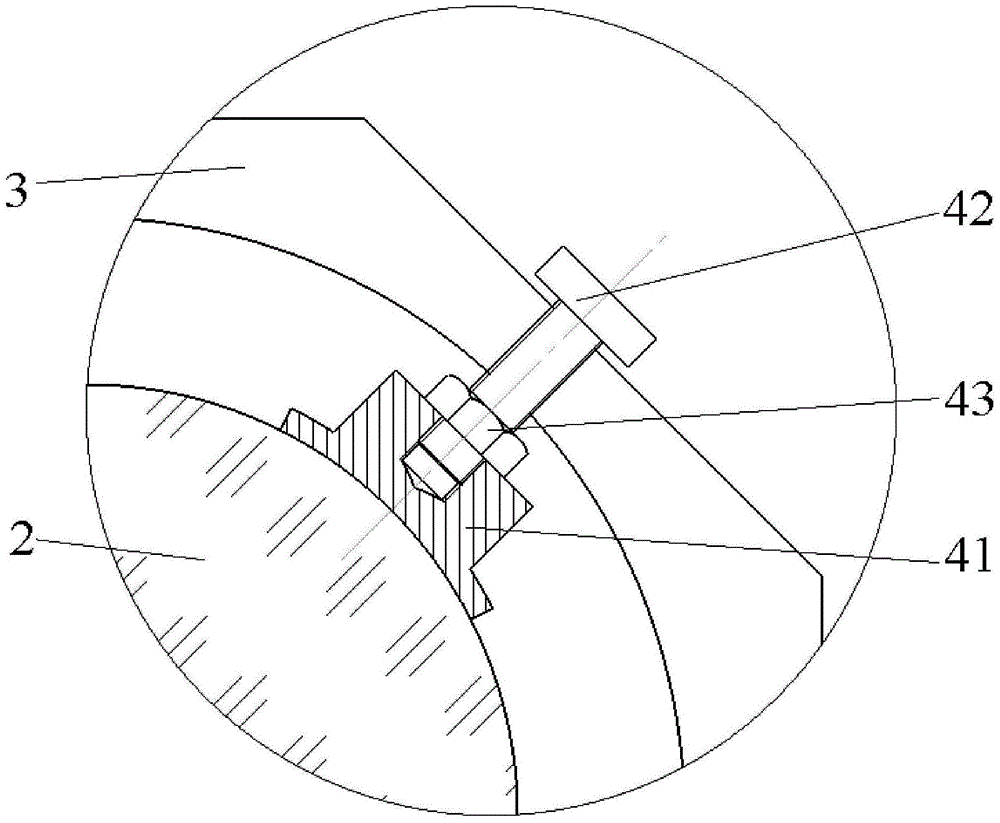

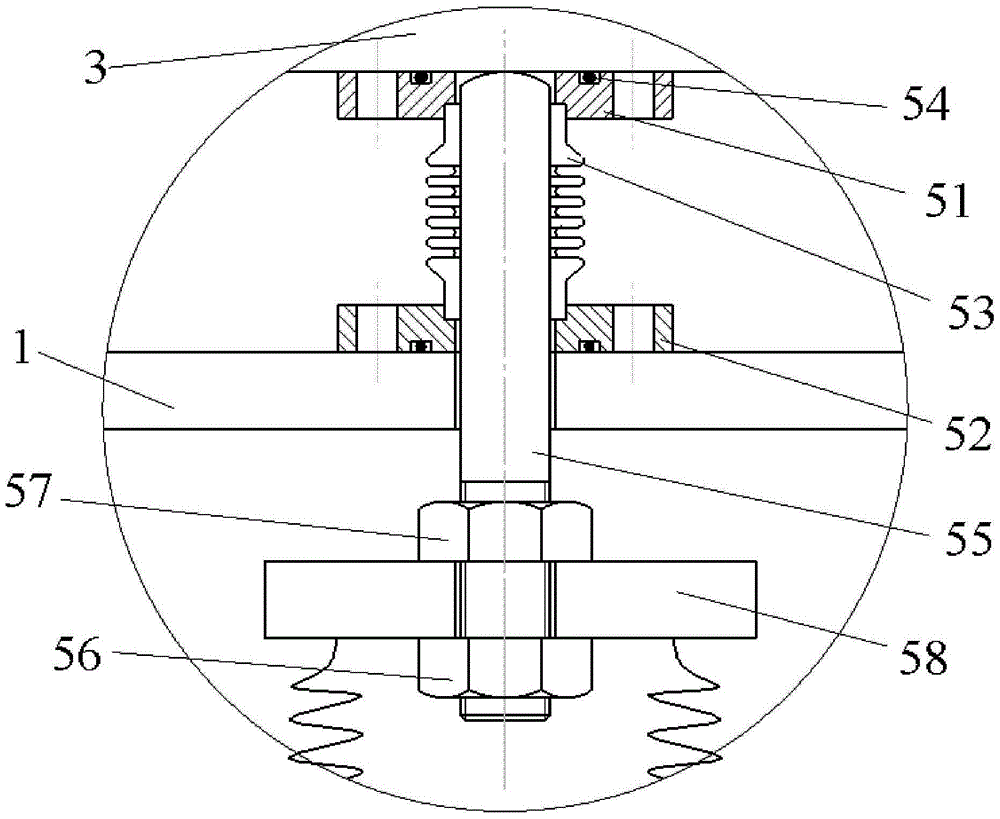

[0023] The lens adjusting device proposed by the present invention is used for installing and adjusting lenses, and is especially suitable for EUV reflective lenses. The adjusting device at least includes a cavity, a lens support frame, a holding pressure system and a support system. The bottom wall of the cavity has a through hole, and the lens support frame is located in the cavity for supporting the lens. The hold pressure system is used to fix the lens on the lens holder. The support system passes through the through hole of the cavity, so that one part of it is located in the cavity, the other part is located outside the cavity, and the part located in the cavity is fixedly connected with the bottom of the lens support frame.

[0024] In order to adjust the height of the lens, the length of the support system is adjustable. That is, a change in the length of the support system will result in a change in the height of the lens support frame affixed to one end of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com