A Design Method of Low Noise and High Pressure Fuel System

A fuel system and design method technology, applied in the direction of charging system, design optimization/simulation, mechanical equipment, etc., can solve problems such as unreasonable design of high-pressure fuel system, difficult to control noise risk, etc., to shorten product development cycle and reduce tests The effect of rounds and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

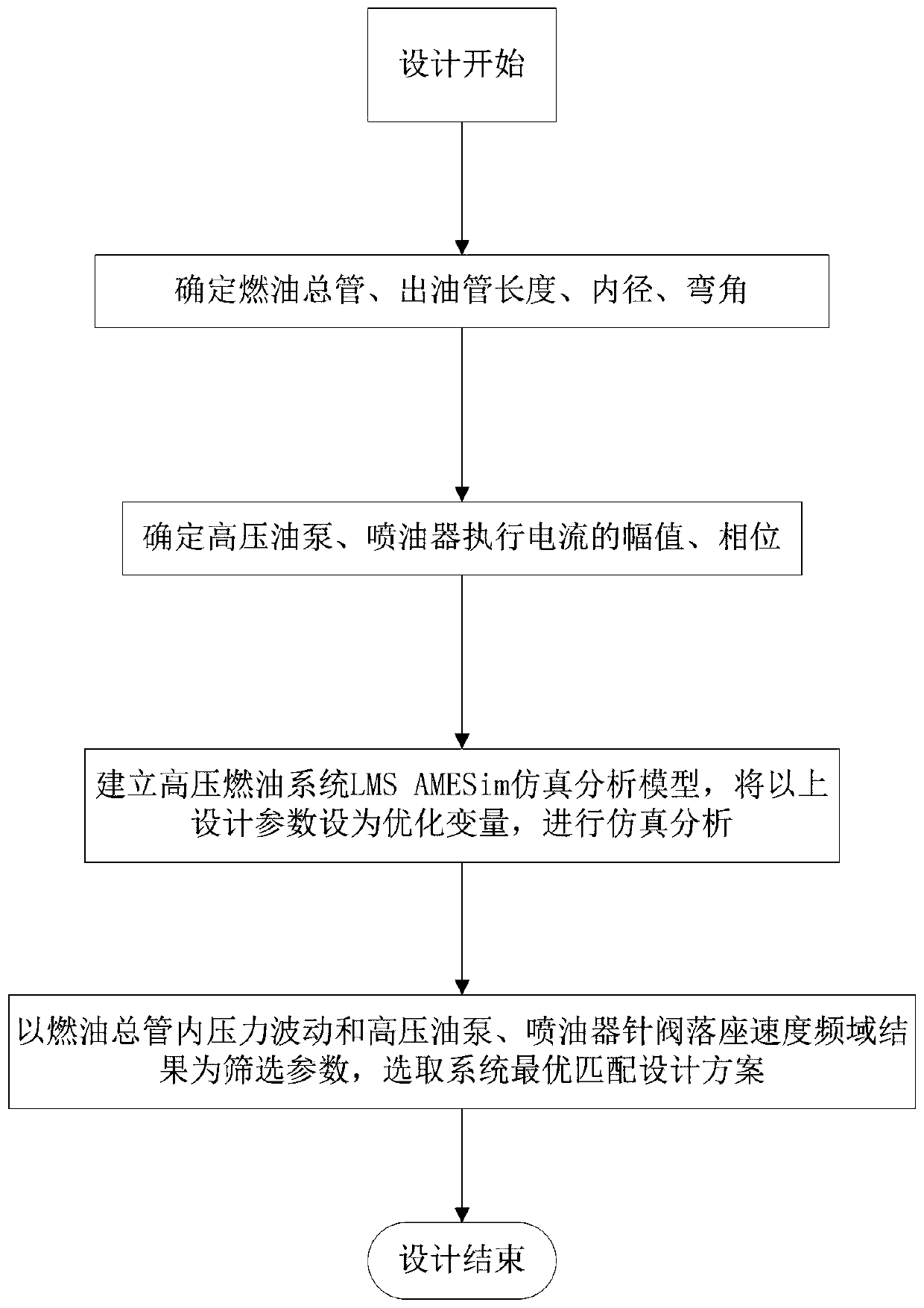

[0025] The following combination figure 1 The steps shown, detail the design process of a low-noise, high-pressure fuel system for a direct-injection engine:

[0026] Step 1: Preliminarily determine the length and inner diameter of the fuel main pipe, the length, inner diameter and bend angle of the fuel outlet pipe.

[0027] According to the engine cylinder center distance (80mm) and the engine length (420mm), the length of the fuel main pipe is initially determined to be 380mm, of which the lengths of cylinders 1 to 4 are all 80mm, and the lengths of both ends are 60mm and 80mm respectively. The inner diameter of the fuel main pipe is based on experience Choose 20mm. According to the general layout of the engine, considering the positional relationship between the high-pressure oil pump and the fuel main pipe, the length of the oil outlet pipe is initially determined to be 200mm, the bend angle is 120deg, and the inner diameter is initially determined to be 8mm according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com