Via hole bent miniaturized PCB_RFID antenna

A technology of vias and antennas, applied in the field of RFID antennas, can solve the problems of single form, too large size of RFID antennas, and lack of aesthetic feeling, and achieve the effect of good performance and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

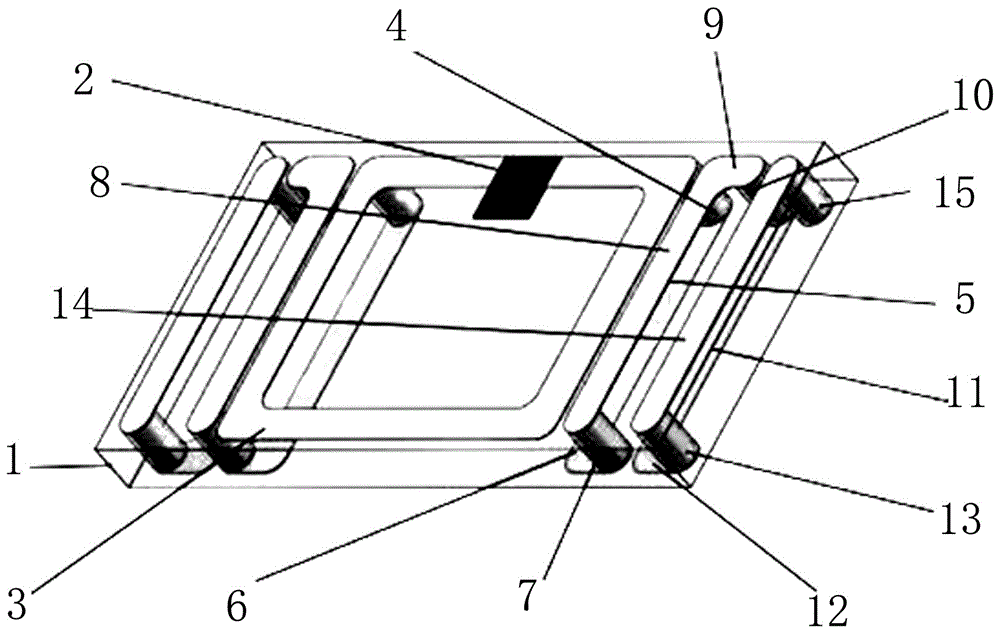

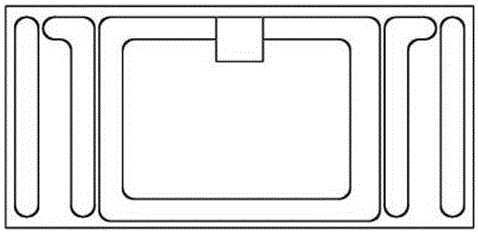

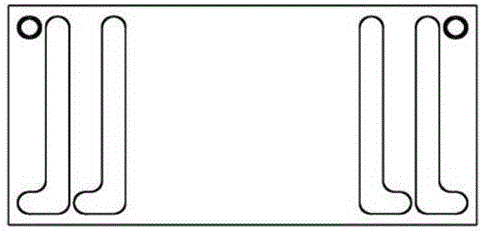

[0019] like Figure 1-3 As shown, the miniaturized PCB RFID antenna bent via holes of the present invention includes a PCB substrate 1, which is made of polyimide or glass fiber epoxy resin material, with a length of 20 mm, a width of 10 mm, and a thickness of 1.6 mm. mm. The antenna is fed by the feeder chip 2 above the substrate, and is symmetrical about the vertical midline of the feeder chip 2, so only the right half of the PCB RFID antenna is marked, and the structural parameters of the left half are exactly the same, and the length of the feeder chip is and width are both 2mm. The matching ring 3 is located on the upper surface of the PCB substrate 1, above it is connected to both sides of the feed chip, the height is 0.035mm-0.036mm, the length of the outer ring is 11mm-12mm, the width of the outer ring is 9mm-9.5mm, and the length of the inner ring is 9mm-10mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com