Electromagnetic actuator and electrical contactor including such actuator

A technology of electromagnetic actuators and electrical contactors, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as weakening the impact resistance of actuators, and achieve the effect of increasing electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

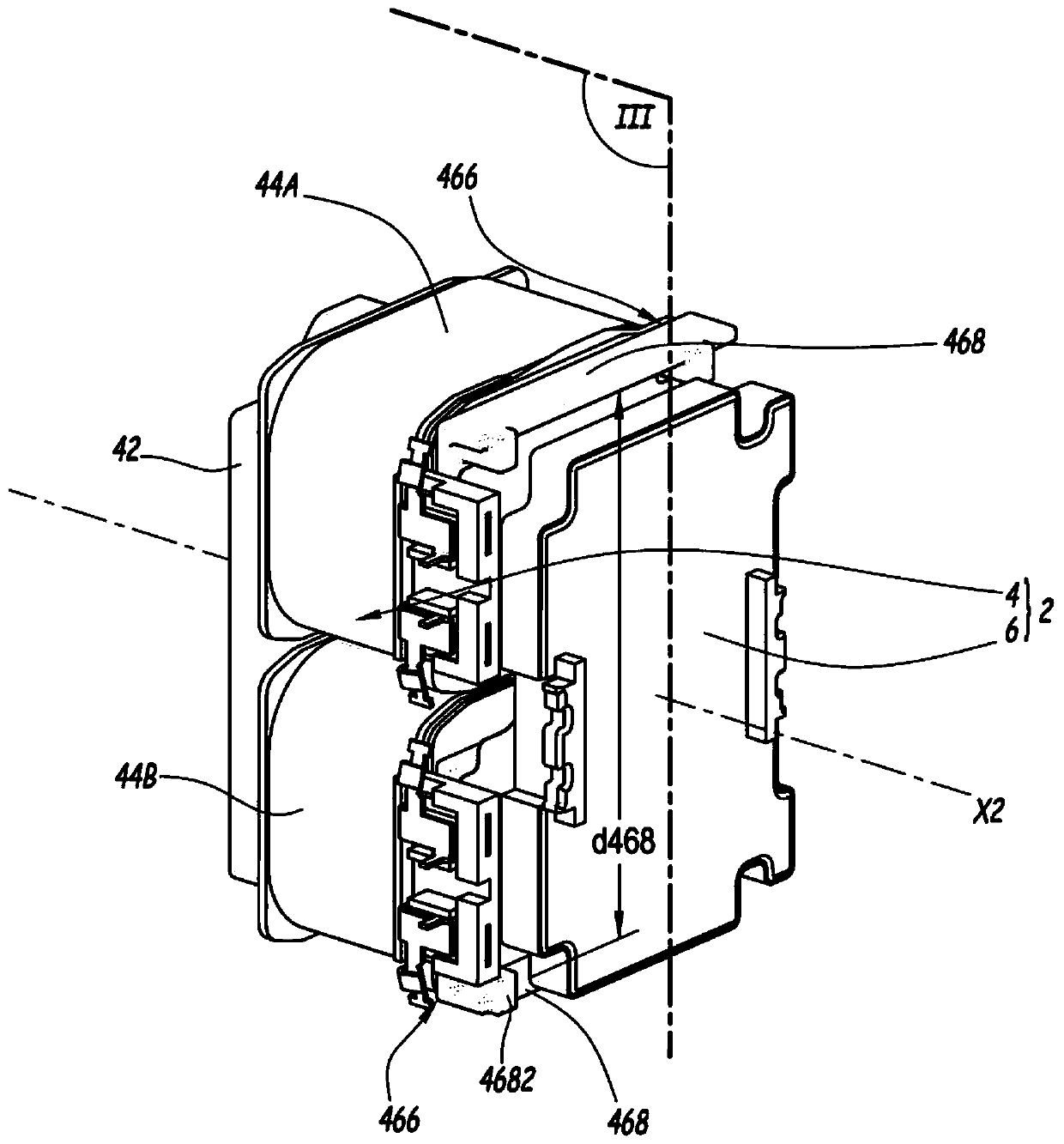

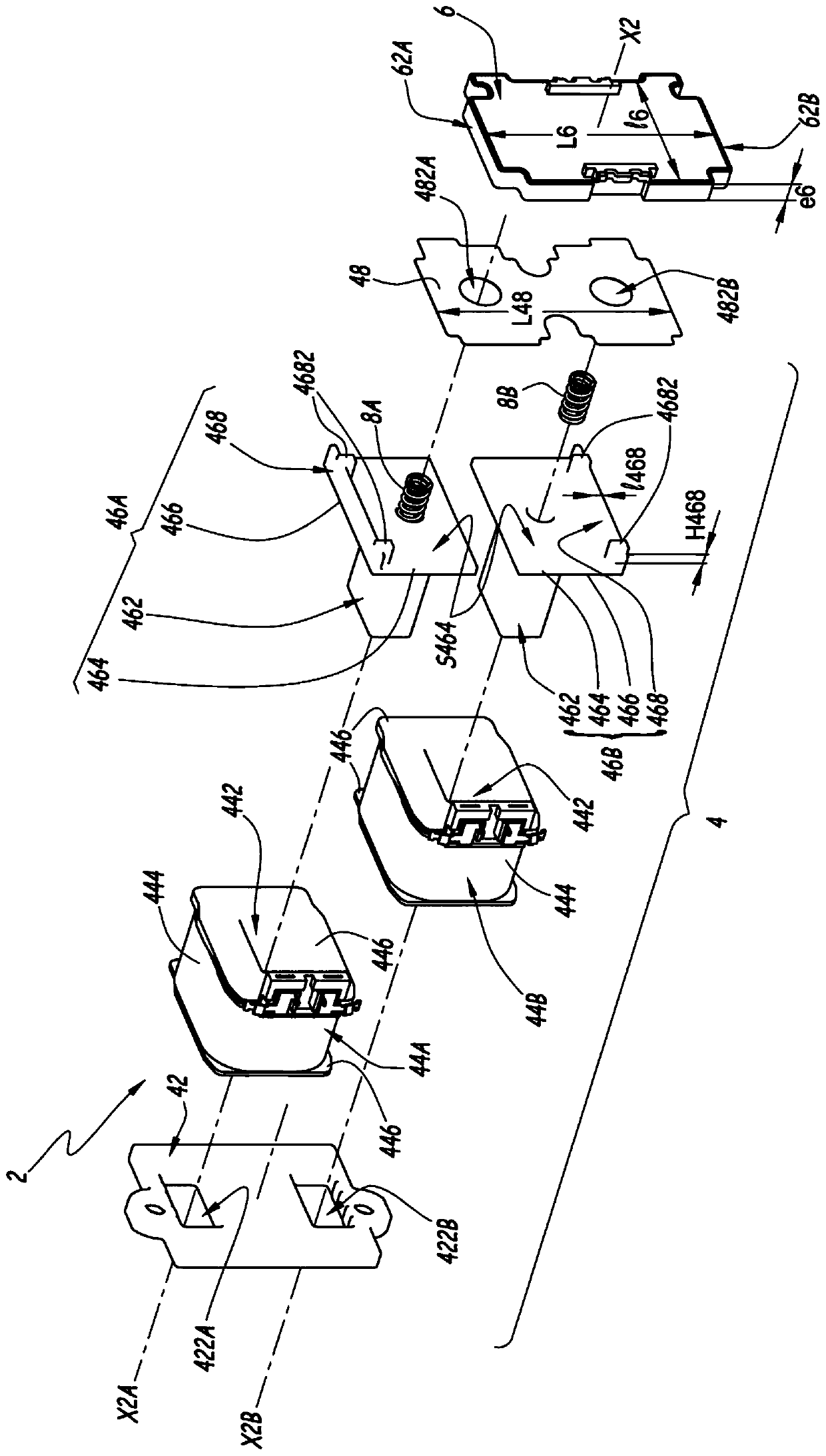

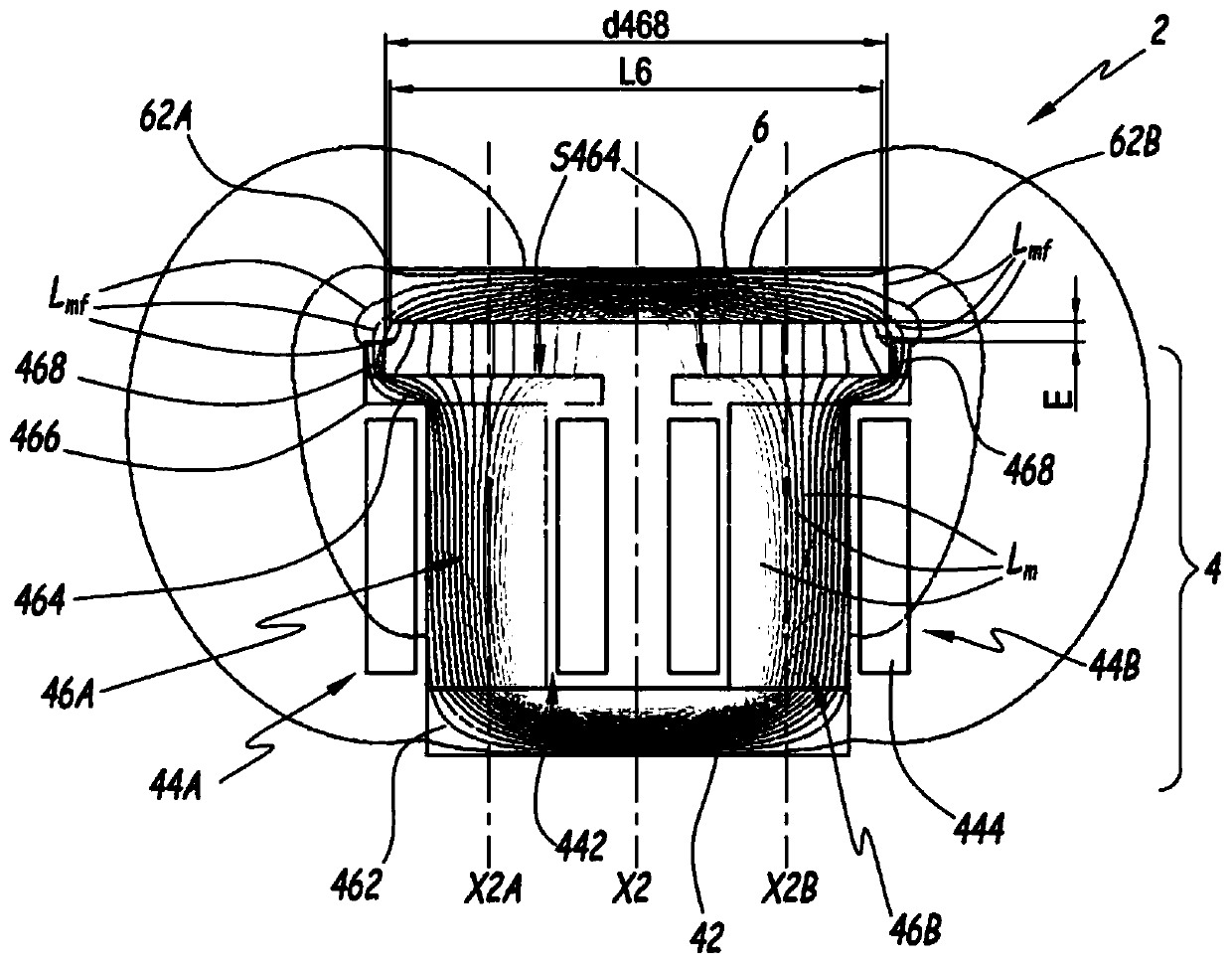

[0026] figure 1 and 2 shows an electromagnetic actuator 2, which is designed for incorporation in Figure 5 In the electrical contactor 200 shown. The actuator 2 comprises a fixed part 4 and an armature 6 movable in translation with respect to the fixed part 4 on the longitudinal axis X2 of the actuator 2 .

[0027] The fixed portion 4 includes a base plate 42 , two identical coils 44A and 44B, two identical cores 46A and 46B, and an air gap spacer 48 . Base plate 42 incorporates two identical orifices 422A and 422B, each centered on axis X2A or X2B, parallel to longitudinal axis X2. Because the coil and core are identical, only coil 44A and core 46A are described in detail. The coil 44A defines a socket 442 around which a winding 444 is wound, disposed between two end plates 446 . The socket 442 for the coil 44A is centered on the axis X2A, while the socket 442 for the coil 44B is centered on the axis X2B. Core 46A incorporates a leg 462 designed to pass through socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com